Produce the Right Part Every Time!

Blacksmith for X7 establishes and streamlines the quality control process for additively manufactured parts. Get to market faster with confidence in your parts. By scanning parts while they print, the X7 is the only industrial-grade FFF 3D printer with in-process part verification.

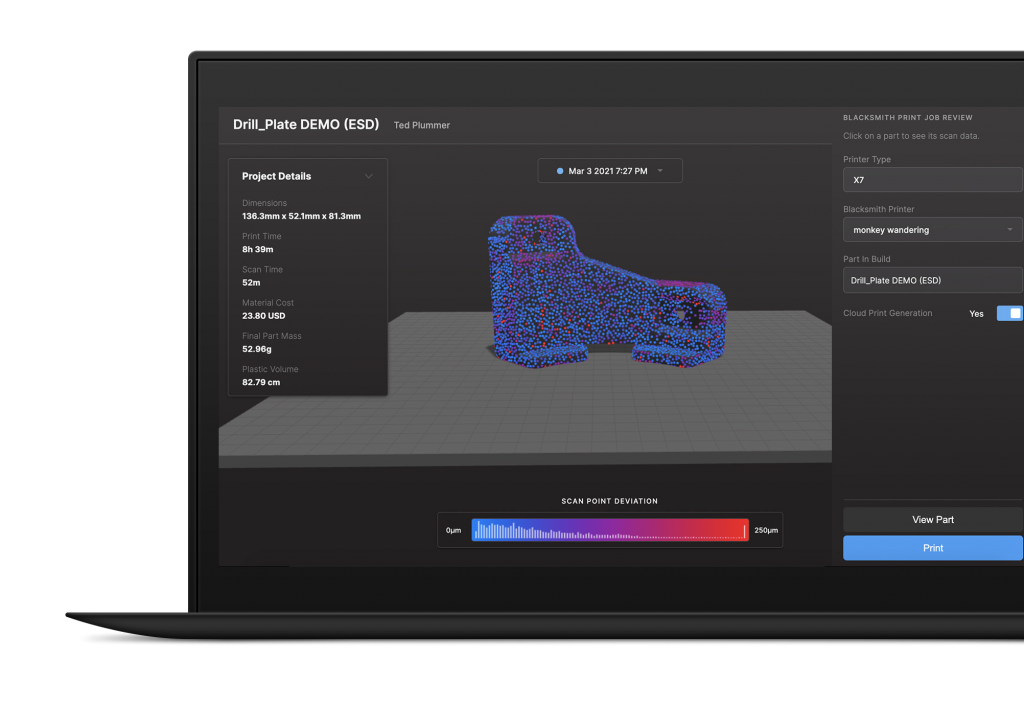

Blacksmith is a subscription feature available through Eiger, the additive manufacturing software for Markforged. It scans, measures, and compares dimensional accuracy data of printed parts to their design files – giving manufactures reliable parts right off the print bed.

Advantages of Blacksmith

Calibrate Machine

A series of automated calibration procedures is completed to ensure each printer is operating at the high standards required for Blacksmith.

Print & Scan Part

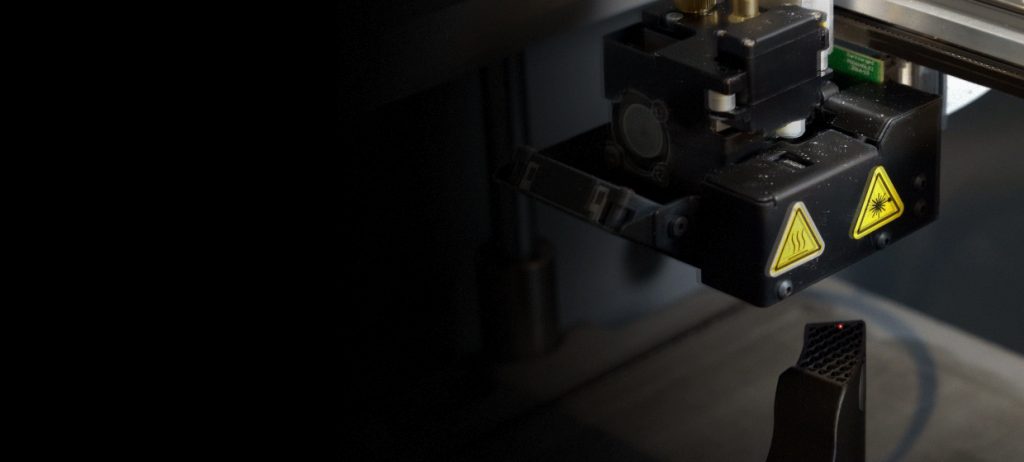

Blacksmith harnesses the power of the X7’s existing integrated laser micrometer and a patented intelligent scanning process to securely measure parts as they are printed.

Compare Scan Data to STL

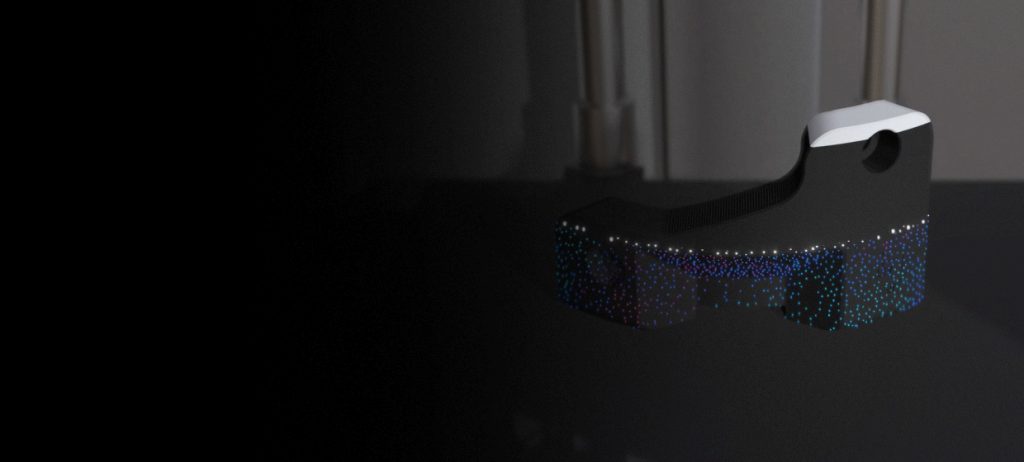

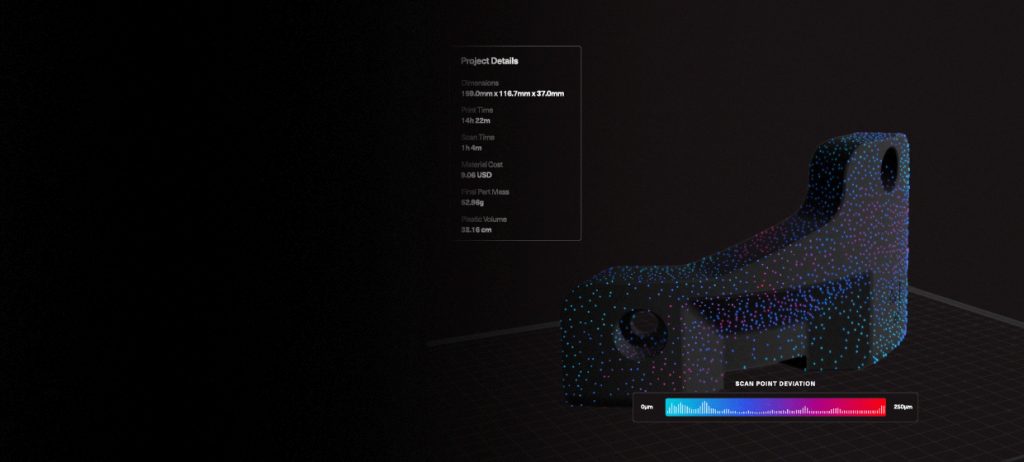

Blacksmith collects measurement data during the print, and assembles a point cloud for review in Eiger. This point cloud is automatically registered and overlaid on the input STL for comparison.

Report Data

View the deviation across the part’s geometry, and set tolerance limits to assess part quality. The print report is saved in Eiger and can be referenced at any future date.

Close the Loop with Adaptive Manufacturing

Blacksmith creates a continuous feedback loop to make parts more accurate. It analyzes a design, compares it to the scanned part, and automatically adapts the end-to-end process to produce in-spec parts. Blacksmith learns continually and adapts to variations in the process over the lifetime of your machine.

Grow Expertise at the Speed of Global Production

Markforged’s AI solution gets smarter with every part, meaning it learns at the speed of global production. Blacksmith makes the world’s factories more efficient, accelerates time to market, and reduces the cost of production.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.