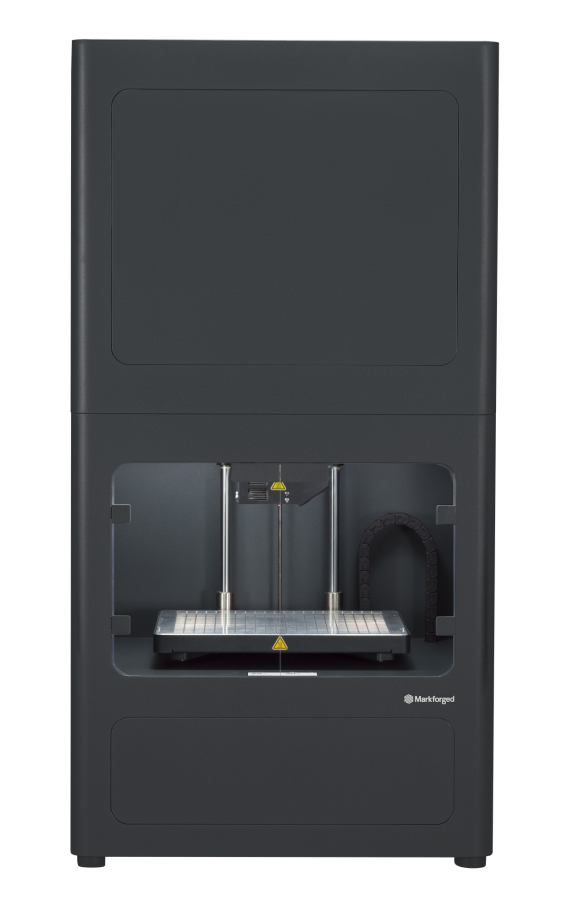

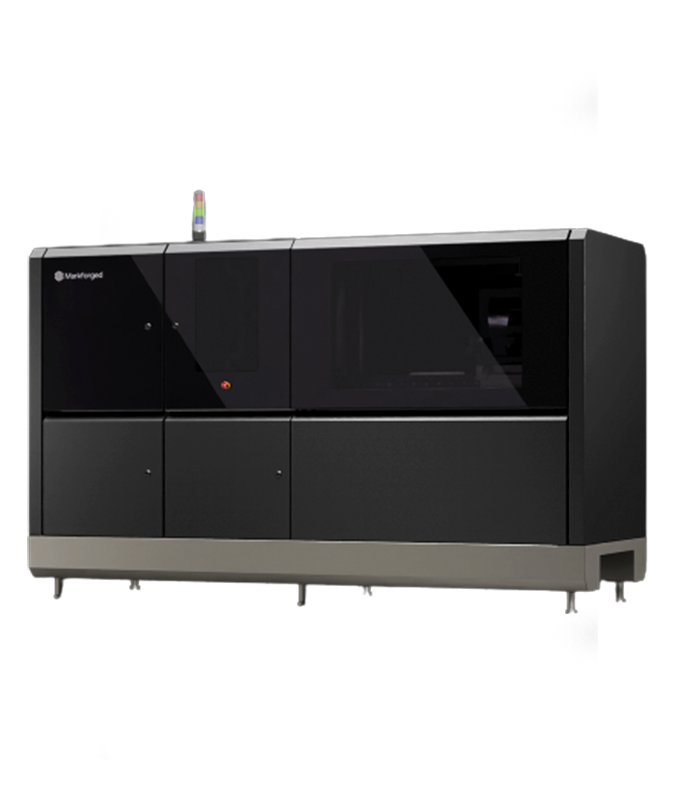

The New Markforged FX10!

The most versatile tool for your factory floor

Markforged’s fifth generation industrial printer. With built-in quality assurance sensors in a modular architecture and automated printing routines, the FX10 takes your manufacturing to a new level. With the same process reliability and reliability, the FX10 produces all components even bigger and better.

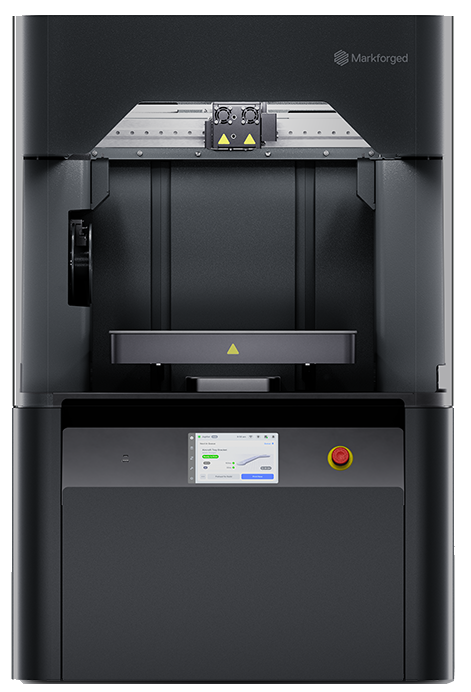

The Markforged FX20!

The beast of additive manufacturing – even bigger, even faster, even hotter.

The FX20 is the largest, fastest and most sophisticated 3D printer Markforged has ever developed. Built for everything from high-performance tools and fixtures to ready-to-fly production parts, the FX20 is the first 3D printer in the Markforged family to be able to reinforce ULTEM™ 9085 filament with continuous carbon fiber. Installation space temperature of up to 200 °C. Up to 8 times faster than previous composite printers.

X7 – Industrial Series 3D Printer

Industrial strength, precision and beauty

With in-process inspection, precision sensors and a large build area, the X Series takes fibre-reinforced strong printing to a new level. As a result, finished parts are exactly as designed, with an unprecedented combination of quality, dimensional accuracy and strength.

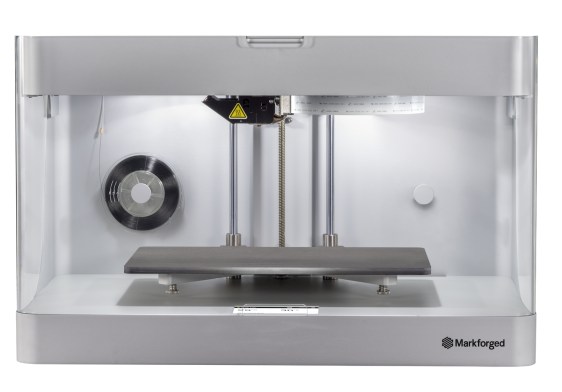

Mark Two 3D Printers

Industry leading strength in a desktop platform

The Mark Two combines Markforged’s unique continuous carbon fibre reinforcement with workhorse reliability. It is capable of producing the strongest, most versatile parts, making it the perfect 3D printer for engineering and manufacturing applications.

Print Materials

The range of reinforcing fibres that can be used include materials such as Kevlar, Carbon Fibre, Fibreglass and High Temperature Fibreglass, using Composite Filament Fabrication (CFF). It is the only printer in the industry, that enables you to go from CAD, to beautiful, strong end-use functional parts and components, such as prototypes, jigs, fixtures, tooling and moulds, in hours. Choose your plastic and reinforcement materials, then put your parts straight in to use as they come off the printer.

Metal X 3D Printers

3D Print Metal Parts

The Metal X printer greatly accelerates innovation. It delivers metal parts overnight using a new technology at a fraction of the cost. Now you can leave 20th century manufacturing behind. Create anything from industrial replacement parts to injection moulds to working prototypes.

The PX100 from Markforged

Metal components from the 3D printer from Markforged

The PX100 is a game changer in binder jetting technology, enabling mass production of everything from industrial components to medical and consumer products. Manufacture complex, production-ready parts where the components are used.

Request a demo!

Feel the strength of continuous fiber for yourself.

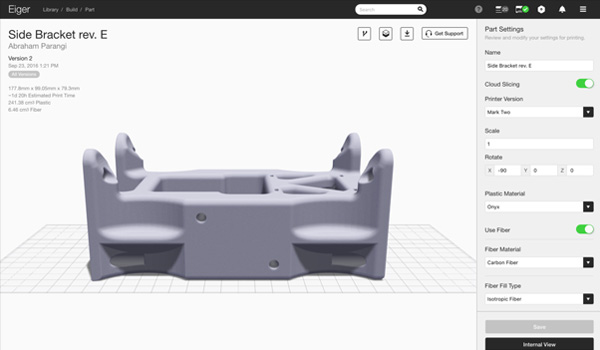

Eiger 3D Printing Software

Organize, Reinforce and Optimize Prints From Anywhere

High-strength, 3D composite printing, requires innovative smart software. Furthermore it requires good, easy to use software. As a result Markforged developed their own 3D printing software – Eiger, so you can easily control the strength and quality of your prints. Whether you have one printer or many, organize, collaborate, and invent in one integrated system.