Metal 3D printing easier than ever before – an industrial revolution

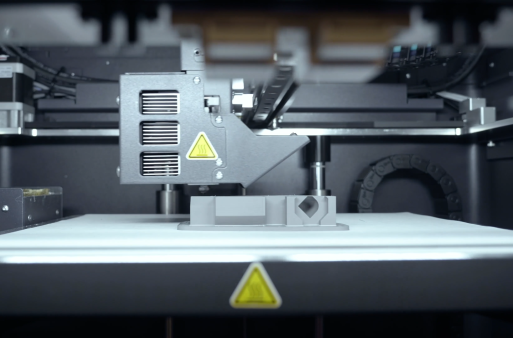

The Metal X delivers metal parts overnight. It uses a new technology and parts are a fraction of the cost of regular metal components. Instantly leave 20th century manufacturing behind, creating anything from industrial replacement parts to injection moulds to working prototypes. Built on already proven technology the Metal X comes as a bundle and includes the wash station and sintering oven. The filament based material is very cost effective making metal additive manufacturing attractive to businesses of all sizes.

ADAM Technology – A brief guide

Atomic Diffusion Additive Manufacturing

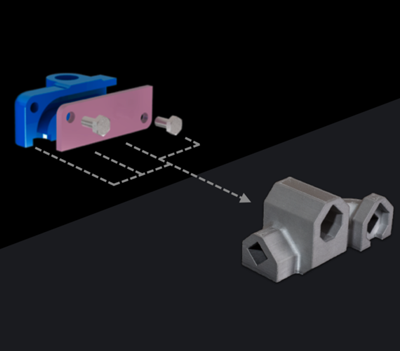

The Metal X uses an innovative technology to 3D print metal. Metal powder appears in the printing material in a very high concentration and is spooled, therefore it can be delivered via a heated nozzle.

This means printing is done by the already proven FDM process. Reassuringly, it’s completely without the toxic metal dust usually associated with metal printing. The sintering process that follows causes atomic diffusion (ADAM). This is due to the heat, the atoms shift slightly and stick together, resulting in an overnight metal part.

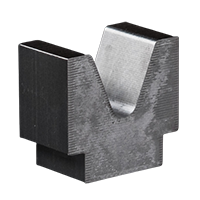

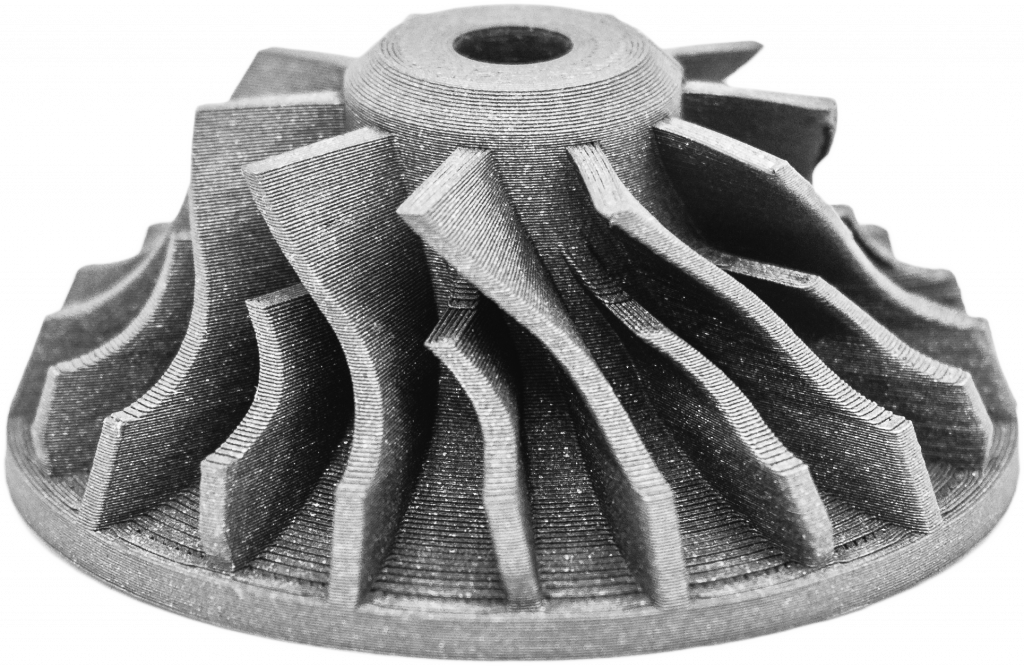

Upon completion the components achieve excellent mechanical properties and enormous rigidity in all directions.

ADAM allows the creation of unique geometry, such as closed honeycomb structures. As a result components that resemble a complex bone structure can also be realised with the Metal X. In other words a closed cell inside, encased in a sturdy outer shell.

Unsurprisingly, this geometry cannot be manufactured with a traditional subtractive methods or even with direct metal laser sintering process (DMLS). This means that the Metal X will allow you and other engineers to find new ways to change the world.

Large construction volume, high-quality resolution

The Metal X has a large construction volume. This enables the production of major components, end-use parts or spare parts in a range of materials quickly and inexpensively.

Components can be printed with a layer height of 50 μm, therefore even the smallest details can have the highest precision.

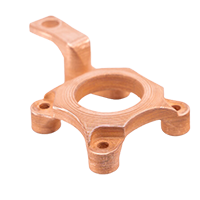

Metal X metals

The combination of proven MIM technology (Metal Injection Moulding) and our unique 3D printing platform allows you to use the same printing materials and processes in both prototyping and production.

Print components with predictable precision and tolerance

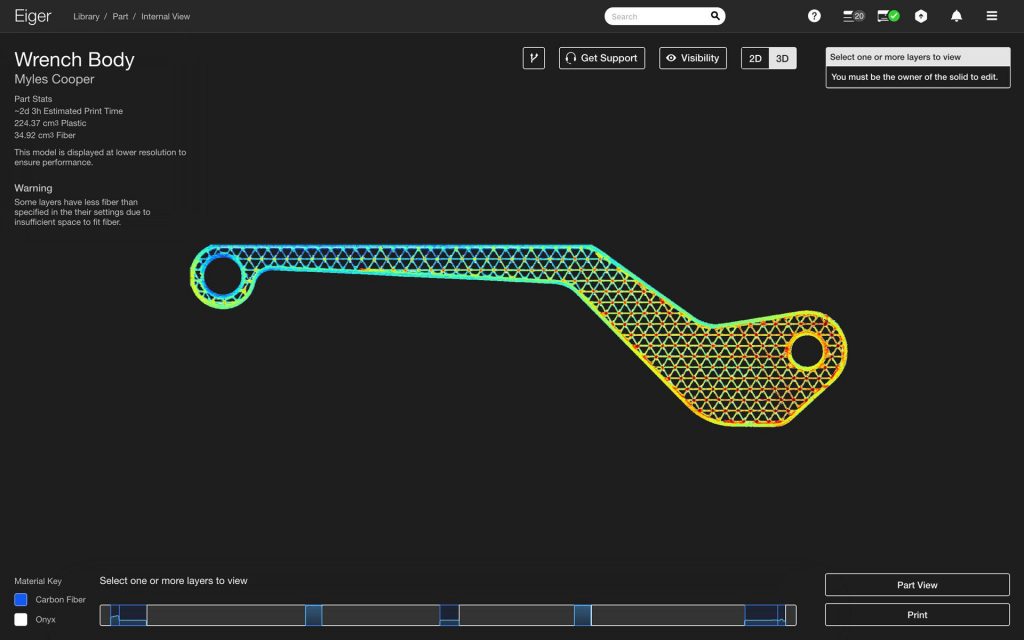

Highly stable 3D printed components designed for industrial applications require innovative and intelligent software. It is for this reason that Eiger is easy to use and allows you to easily control the stability and quality of your prints. With a cloud version shipped with every machine, Eiger offers you the benefits of automatically improving functionality, through seamless updates.

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.