Fiberglass

What is Fiberglass?

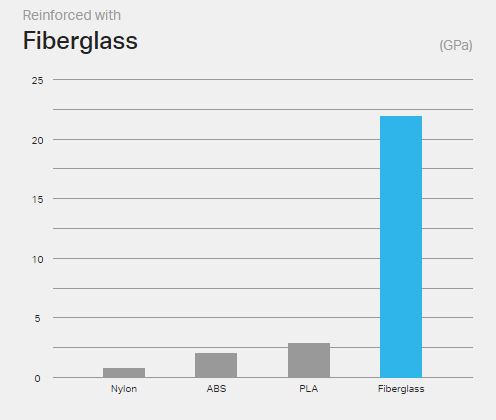

Inexpensive and 11 times stiffer than ABS, fiberglass is the perfect entry-level fiber for 3D printing.

When schould I 3D print Glassfiber?

Use fiberglass composite material to print parts that are an order of magnitude stiffer than typical 3D printed objects at the most affordable price.

Functional prototypes

Jigs

Fixtures

End Use Parts

3D Printed Fixtures for Laser Welding Machines

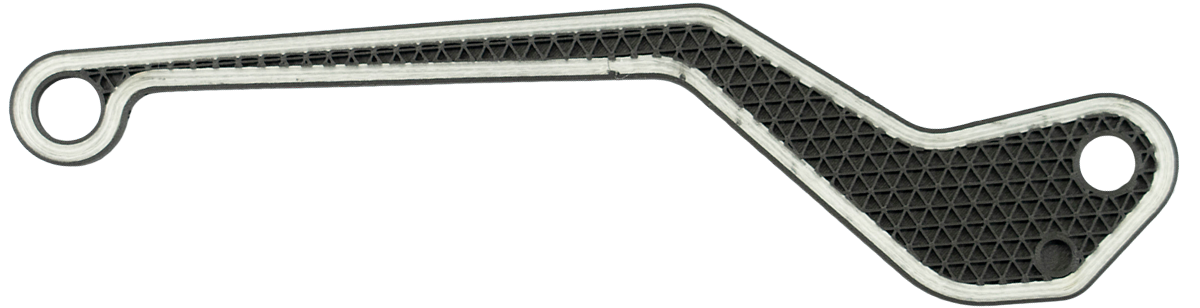

Primetall GmbH was faced with the challenge that different fixtures were required for a laser welding system, as they had invested in a new system. Until now, these jigs were conventionally made of aluminum.

Request a demo!

Feel the strength of continuous fiber for yourself.

FAQ

What is Fiberglass material? Extremely thin strands of glass bundled together into a fiber. Fiberglass is traditionally used in composites for boat, automobile, and aircraft manufacture.

How strong is Fiberglass? Fiberglass has a flexural strength of 200 MPa (29.0 ksi) and a tensile strength of 590 MPa (85.5 ksi). For more information on 3D printed fiberglass material properties, check out the data sheet.

What does the Fiberglass filament cost? A 50cc spool costs £64.00 excl. VAT and a 150cc spool is £184.00 excl. VAT.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.