Industrial Series Printers

Uncompromising Strength, Precision and Beauty with Markforged Industrial Series Printers

The Markforged Industrial Series of 3D printers takes fibre-reinforced 3D printing to a whole new level with a laser-assisted construction process control, precision sensors and a large working area. Finished parts are printed the same way they were designed with unmatched quality, dimensional accuracy and stability.

These printers combine the benefits of Markforged’s unique fibre reinforcement for parts as strong as metal with advanced “build as designed” sensors and the beautiful surface finish of Onyx. The Industrial Series will empower you to take any design concept and make it a reality.

Large Prints, High-Resolution

The large build volume of the Industrial Series makes it ideal for robotics, automotive parts, functional prototypes and prosthetics. With 50 micron resolution layer height, your parts will come out of the printer with a beautiful surface finish approaching the look and feel of injection molding.

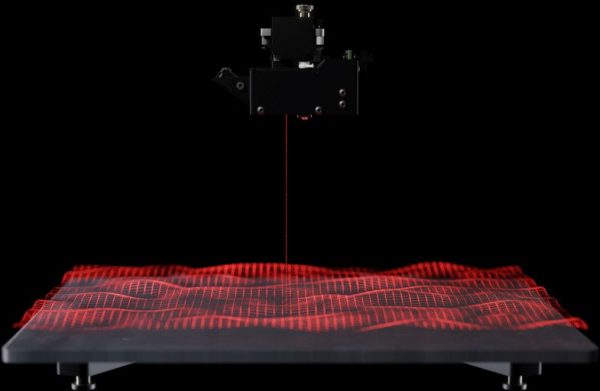

In-Process Inspection

The Markforged Industrial Series gives you breakthrough quality and precision in 3D printing. Scan your parts mid-print using our cloud-based Eiger software and a laser displacement sensor affixed to the print head. Ensure dimensional accuracy at the most critical tolerances at any point in your print.

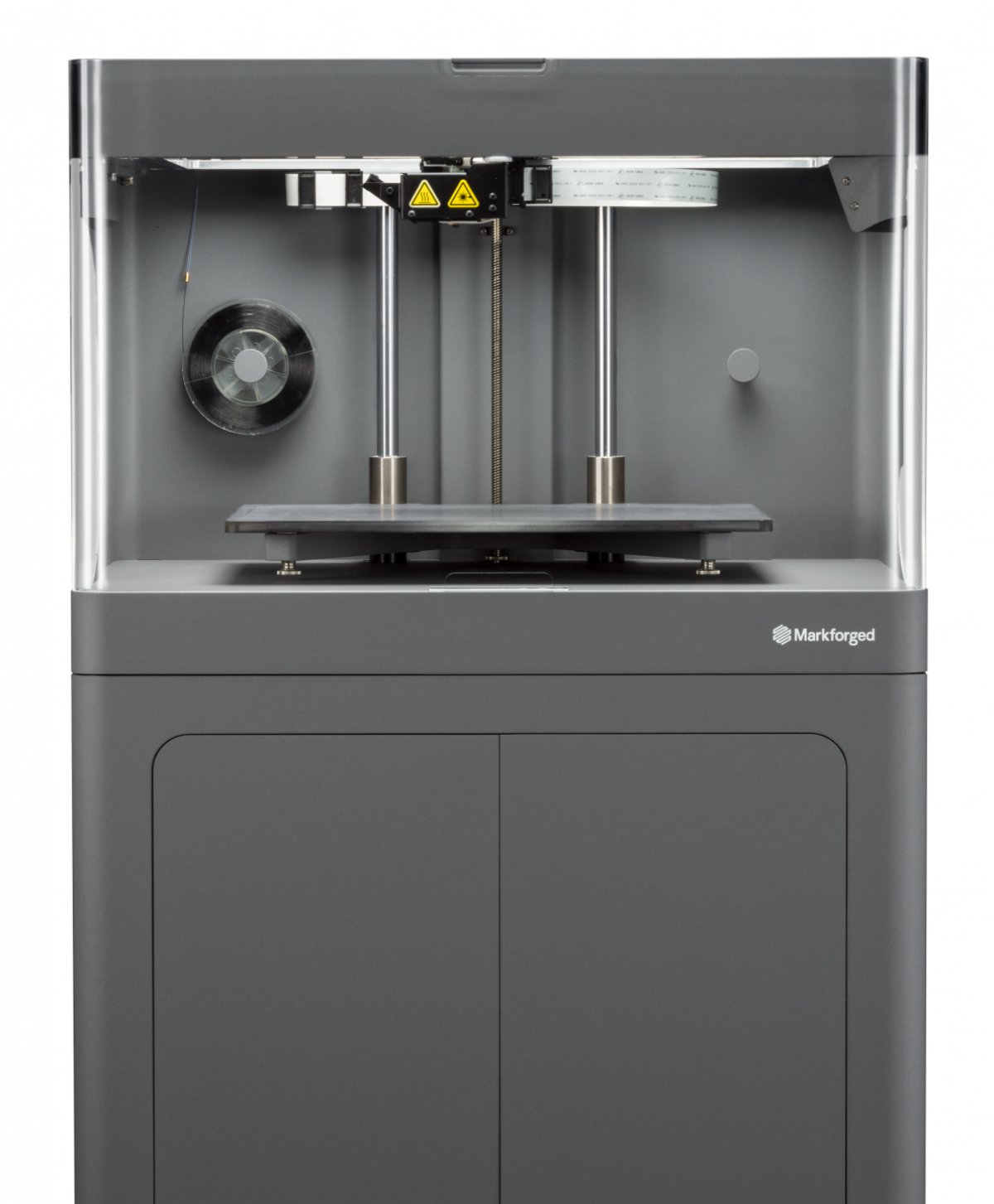

The X7

The turnkey industrial 3D printer for functional parts of all types

Basic Materials: Onyx, Onyx FR, Onyx ESD, Nylon Composite Materials: Carbon Fibre, Kevlar®, Fibre Glass, HSHT Fibre Glass

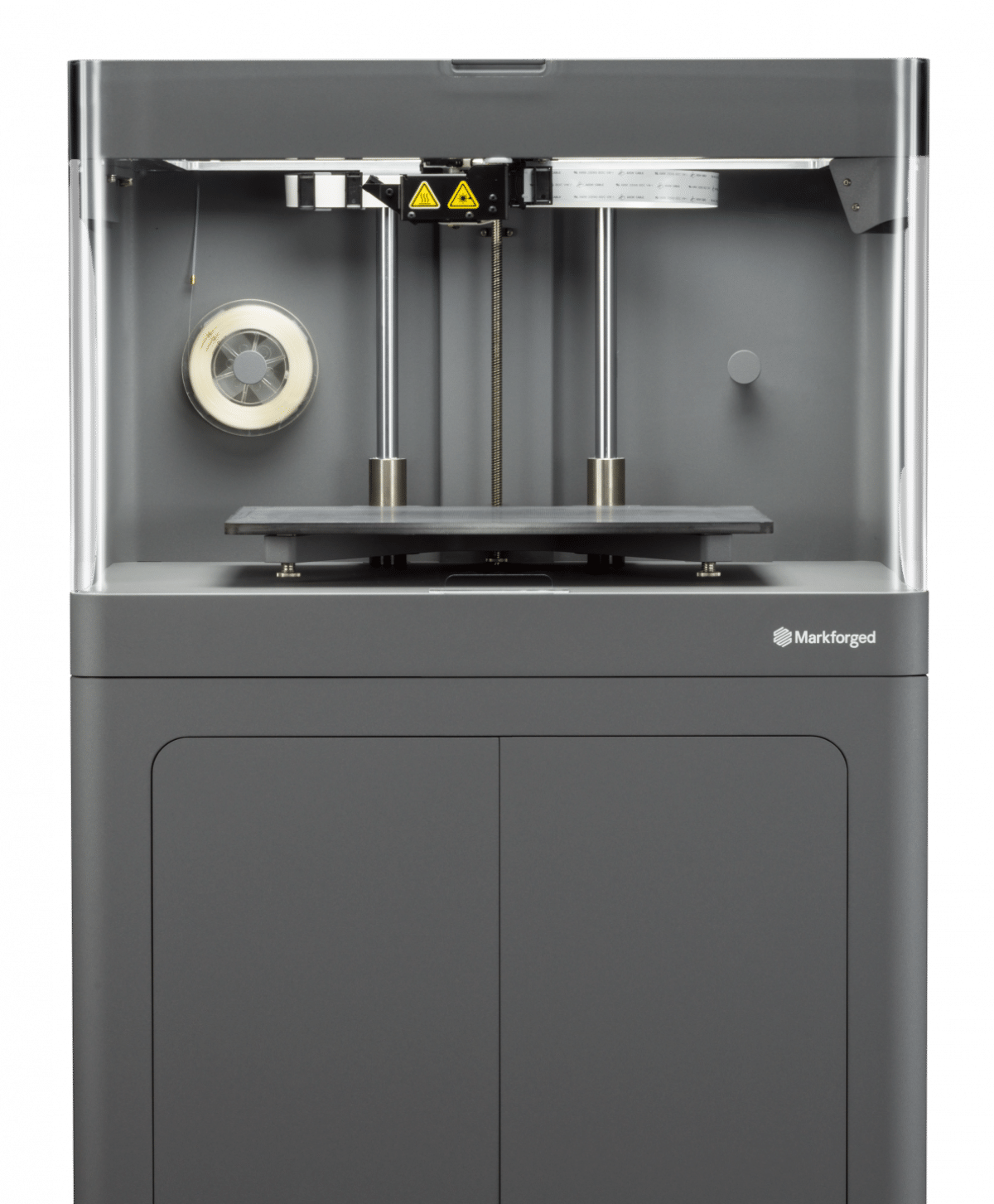

The X5

The workhorse industrial 3D printer for fiberglass reinforced parts

Basic Materials: Onyx, Onyx FR, Onyx ESD Composite Materials: Fibre Glass

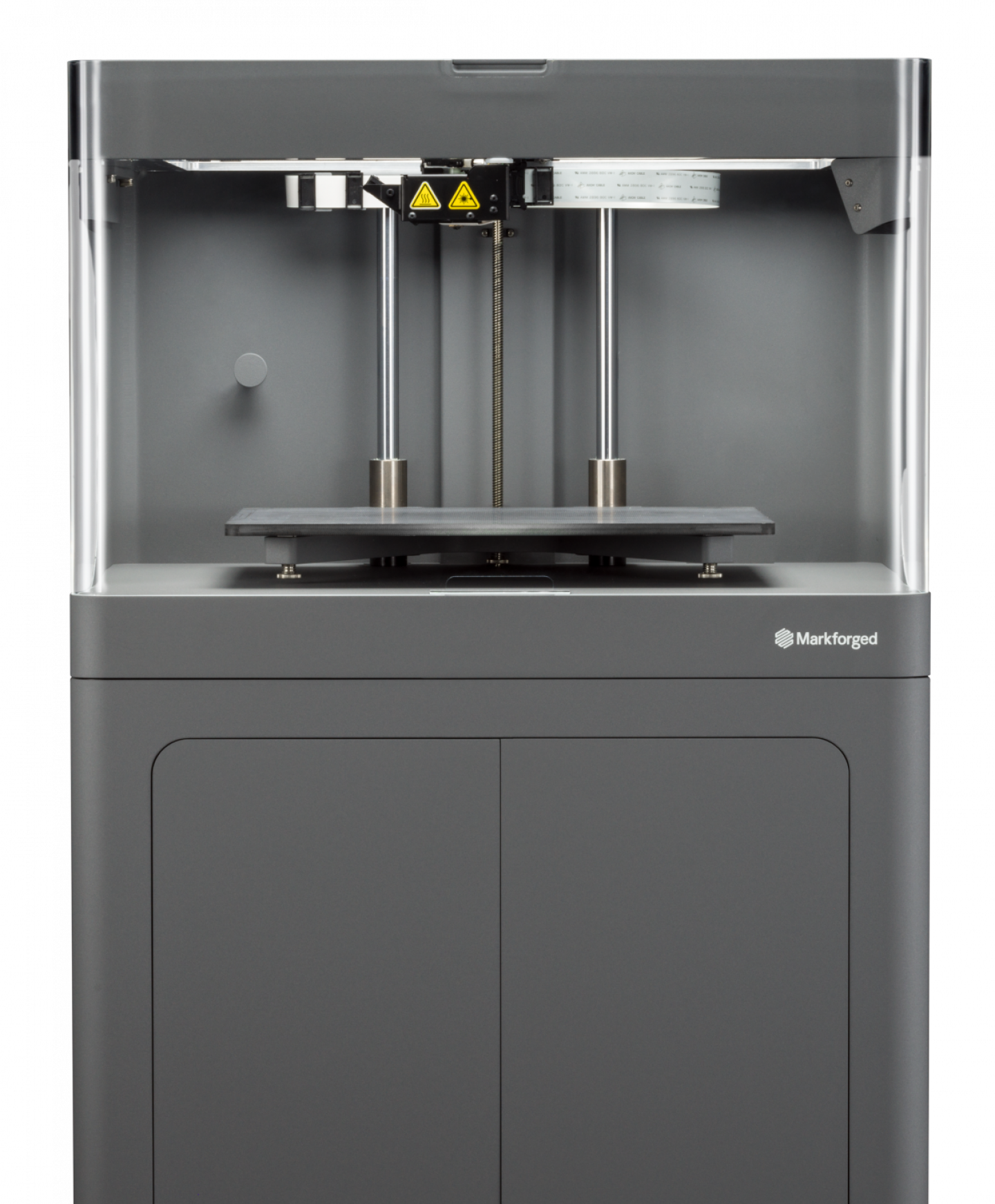

The X3

The refined 3D printer for useful plastic parts

Basic Materials: Onyx, Onyx FR, Onyx ESD

Print As-Designed Parts With Known Precision And Tolerance

Define a tolerance specification in Eiger, our cloud based 3D printing software, and the Industrial Series will scan your part while it’s printing to ensure that it always meets the spec. If an error is detected you will be alerted and can choose to cancel the print remotely, saving time and material.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.