A2 Tool Steel

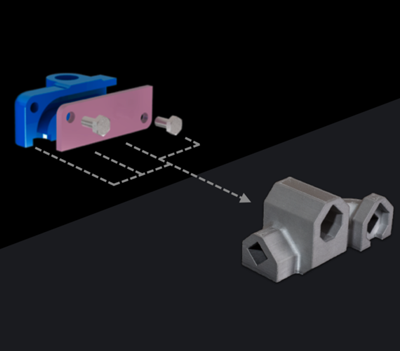

General purpose tool steel for cold-working applications.

When should I 3d print A2 Tool Steel?

A2 Tool Steel is a highly versatile air-hardening tool steel often regarded as a “universal” cold-work steel. It offers a combination of good wear resistance (between O1 and D2) and toughness.

Sheet Metal Fabrication

Forming Prototypes

Punches

Dies

Request a demo!

Convince yourself of our A2 Tool Steel.

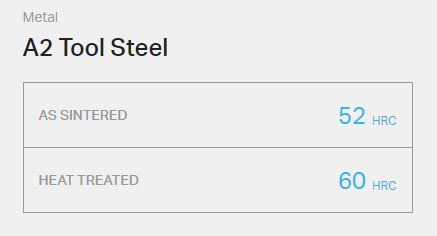

Working with A2 Tool Steel

A2 Tool Steel can be heat treated to increase hardness and durability. Markforged recommends heat treating A2 Tool Steel to optimize material properties, though it can be used as-sintered. Heat A2 Tool Steel part in a standard (non-vacuum) furnace to 970°C (1780°F). Hold part at temperature for 30-45 minutes. Air quench part to below 65°C (150 °F). Double temper A2 Tool Steel part in a standard furnace. For each temper, heat part to 150-550°C (302-1022°F) and temper for 2 hours, or 1 hour per inch of thickness. Let part cool to room temperature between tempers.

Compatible with our Metal X system.

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.