Industrial 3D printing in practice.

Case studies and practical examples of Markforged 3D printers

In the automotive, aviation, automation & robotics, electronics and many other industries, Markforged technology is already being used by the world’s leading companies to explore innovations faster and at lower cost. Below are some of our success stories!

Industrial 3D printing in practice.

Case studies and practical examples of Markforged 3D printers

In the automotive, aviation, automation & robotics, electronics and many other industries, Markforged technology is already being used by the world’s leading companies to explore innovations faster and at lower cost. Below are some of our success stories!

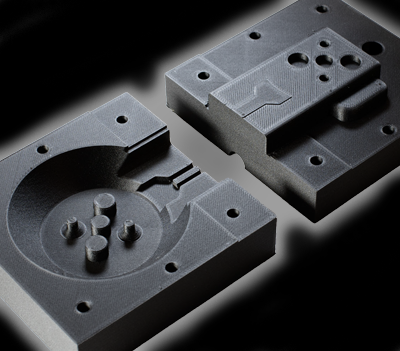

3D Printed Fixtures and Die Sets

See how DANA Incorporated reduced the cost of their tooling by 70%, and reduced lead times by 90% 3D printing in factories across 7 countries.

End-Use 3D Printed Racing Car Parts

See how Garry Rogers Motorsport made cost and time savings of 92% by 3D printing hundreds of end use parts for their racing cars.

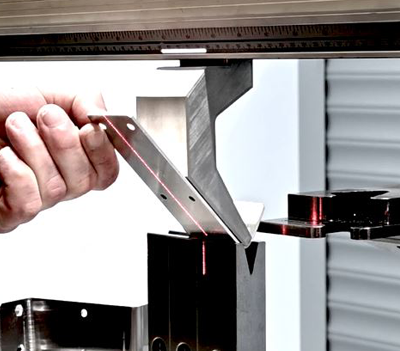

Sheet Metal Press Brake Tooling

See how Concept Metal saved 75% on costs by 3D printing their sheet metal shaping press brake tooling, replacing outsourced steel.

Tube Bending Dies, Welding Fixtures

See how Toivallan Metalli saved 90% of their manufacturing costs by 3D printing their tube bending dies and fixtures.

End to End Manufacturing

Watch this case study to see Caldwell Manufacturing 3D print everything from prototypes and end use parts to jigs and fixtures.

Aircraft Refit Cabin Components

Cabin Management Solutions provide a cost-effective, quick turn around, bespoke 3D printed components for aircraft cabins with Markforged.

Lightweight 3D Printed Satellites

Sidus Space make significant weight savings and rapidly develop their satellites with Markforged’s aerospace certified materials.

Spare Parts for Food and Beverage Industry

The Australian Meat Processor Coporation 3D print universal spare parts for their production lines, avoiding costly downtime in the food and beverage industry.

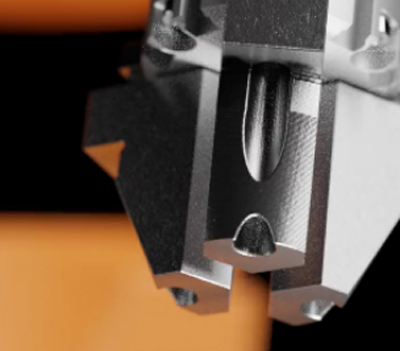

Robot Grippers with Internal Vacuum Tubes

Harvestance 3D print affordable, custom robot vacuum grippers with internal vacuum channels.

Resilient Aerospace Manufacturing

ISS Aerospace internally manufacture drone parts quicker and cheaper with Markforged, and protect against supply chain disruption.

Prototypes and Development

Sonic Communications Cuts Product Development Time by 75% while reducing dependence on their machine shop.

Electronic Industry

FESTO relies on 3D printing with Markforged for their electronics component manufacturing.

Prototypes

Guhring UK is printing a second metal prototype and can use it for initial cutting trials, which is a major competitive advantage.

Hydraulic Post Driver

Stanley Black & Decker has replaced a four-part assembly with a single, ready-to-use component. The cost and time savings are huge.

Production parts

3D printing in production is a reality for Clenaware Systems – end use parts parts on-demand from the 3D printer. Reduce lead times.

Resources

The challenge with 66 different saw blades is to make production as productive as possible despite the high variety.

Spare Parts

Serial spare parts production with industrial 3D printing at mayer-technology GmbH & Co. KG

Automation

The requirements for printed components for robotics are stability and, at the same time, the lowest possible weight.

Exploration Robots

Functional parts that do not require any post-processing makes Markforged an ideal additive manufacturing technology.

Lifting tool

Wärtsilä manufactures the world’s first 3D-printed CE-certified hoist and can lift a whole 960 kg (with safety factor 4)!

Spare Parts

Learn how DUNLOP has achieved a very fast ROI and why they believe that technology will play an important role.

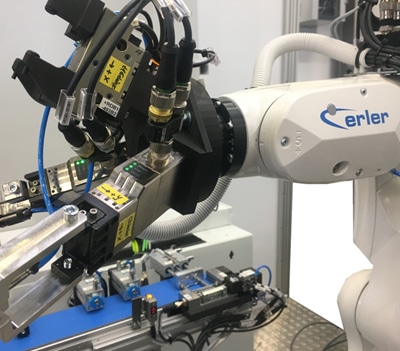

Automation

The aim of erler GmbH was to bring the added value in-house in order to obtain more flexibility, independence and economic efficiency.

Medical parts

A new product launch turns in to so much more – Compensation of supply chain delay and faster and cheaper production preparation.

Automotive parts

RPG Industries, Inc. needed a new carburettor cover for a classic car, but it was no longer available anywhere in the world! A conventional production was simply too expensive.

Circular saw housing

Siemens Gas & Energy is printing a custom onyx circular saw housing with integrated parts such as the engine and shovel to repair gas turbines.

Chain links

Agricultural machinery manufacturer CLAAS prints chain links made of nylon and glass fibre for transporting combine harvesters weighing over 17 tonnes.

Functional Prototypes

BAM GmbH offers a wide range of products for the manufacture of metal and plastic components of the highest quality and with the narrowest tolerances for numerous industries.

Aviation

VOCUS uses the self-extinguishing and flame-retardant Onyx FR as the material for the battery packs.

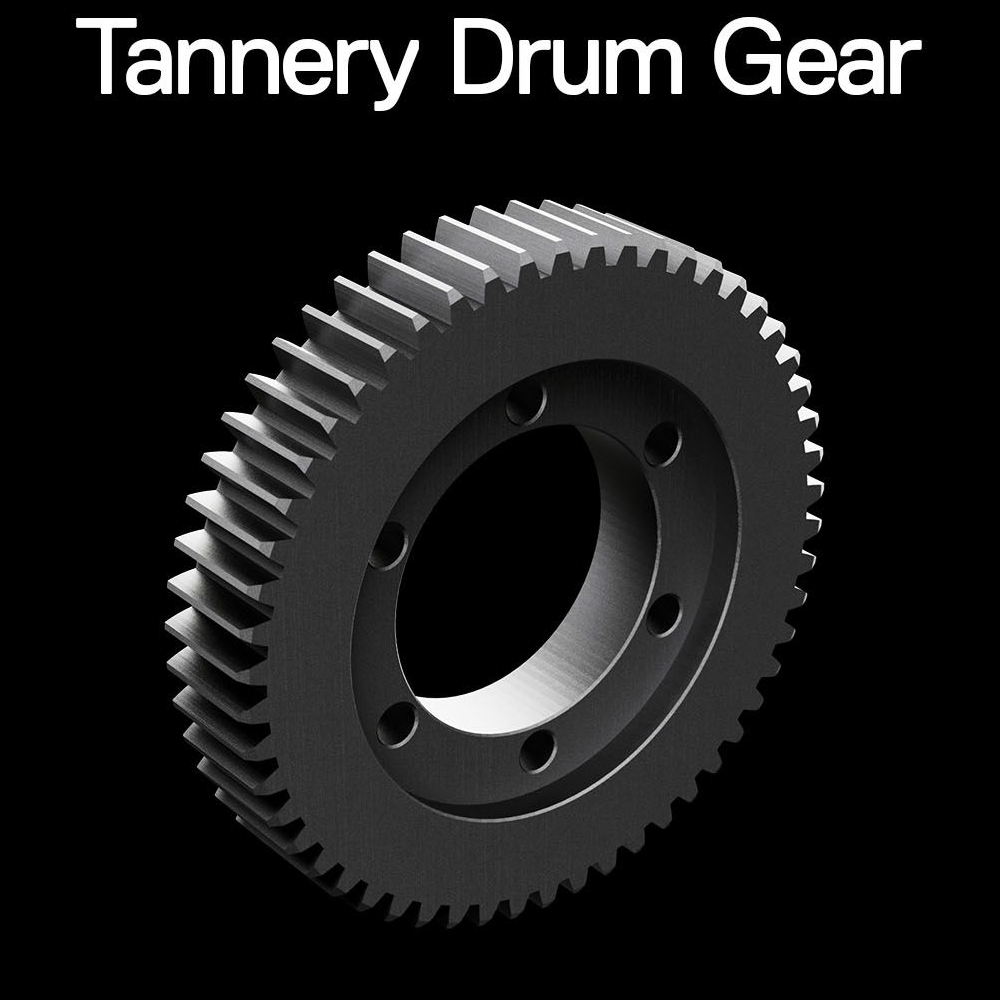

Gears

3D printing in plant construction from prototype to series production. Development and production of a novel blasting technology for homogeneous and reproducible surfaces.

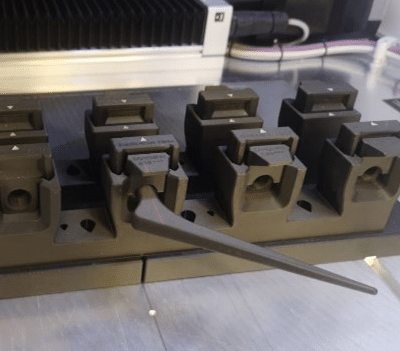

Fixtures

Individual fixtures for a laser welding system used to be made of aluminium and were very heavy and expensive to produce.

Sample part

See for yourself the quality and strength of a sample component reinforced with continuous fiber.

Special machine construction

The main focus is on special machines, which is why almost no component occurs twice.

Individual parts

Cirnapro designs metal and plastic parts for the mechanical engineering industry in lot sizes 1-200. 3D printing allows complicated functions to be integrated into a single component.

Sanitary valves

Speed plays a particularly important role in the development phase of a new valve.

Reverse Engineering

DAVOSCAN uses five Markforged 3D printers and can rest assured that no matter which 3D printer they use, the result will always be the same.

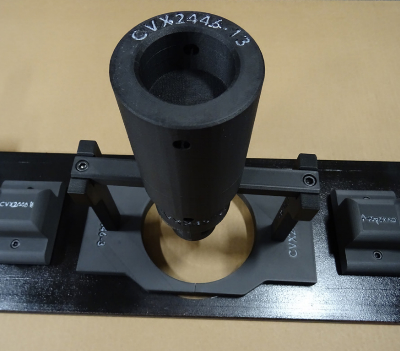

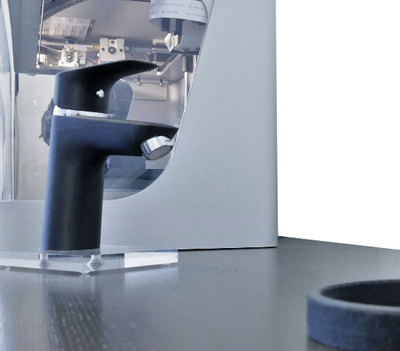

Nozzle holder

Siemens Gas & Energy prints customized onyx devices to keep custom injectors during post-processing.

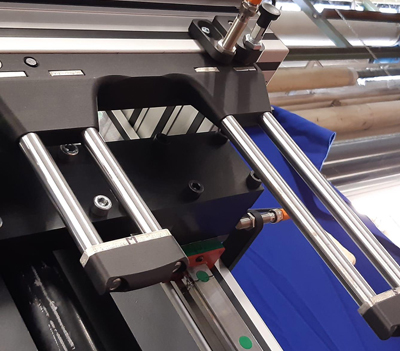

Tooling

Reducing changeover time and increasing plant throughput with Markforged technology

Surgical Instruments

Fusing Metal and Carbon fiber printing to create prototype tools for surgical use

Prototypes

Kessler Plastics GmbH is a specialist in injection moulding technology and contract manufacturing and sees itself as a complete supplier in this field for its customers.

Robo Challenge

Robo Challenge is a creative engineering company that pushes design and materials to the absolute edge.

Tangible applications and benefits of using Markforged 3D printers

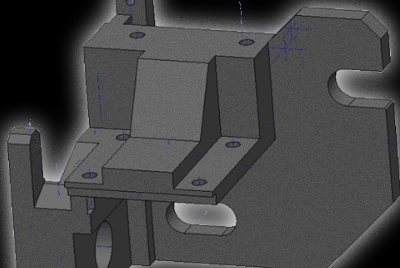

Welding Jigs and Fixtures

99% cost saving 93% time saving No more human error Faster and easier

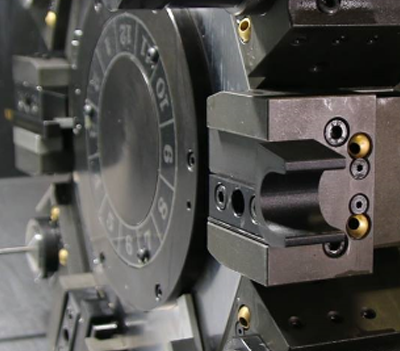

CNC Milling Workholding Vice

75% cost saving 66% time saving Custom vice and jaw Low profile clamping

ProCobots Custom End Effectors

97% cost saving 88% time saving Adaptable robots Lighter than aluminium

CMM Fixtures for Aerospace Inspection

80% cost saving 70% time saving Complex geometries Minimal deflection

In-Flight Entertainment Retrofits

High quality, aerospace compliant cabin controls for luxury aircraft refits.

Safety Guards for Production Lines

How companies are rapidly complying with safety requirements with 3D printing.

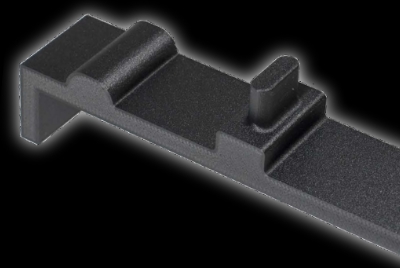

Custom Push-Plates for Production Lines

Why 3D printing custom push-plates in packaging production lines is more efficient than conventional manufacturing.

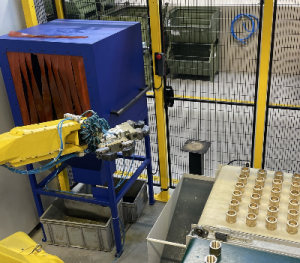

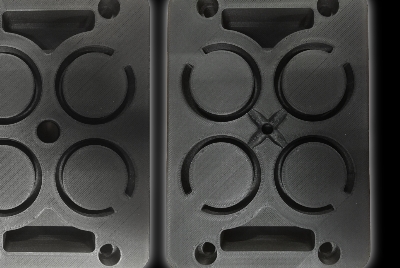

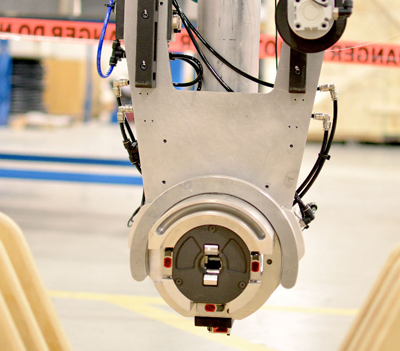

End of Arm Tooling for Robots

Why leading companies have switched to 3D printing their vacuum gripper tools for their packaging robots.

Sample part

See for yourself the quality and strength of a sample component reinforced with continuous fiber.

If you would like a demo, have any questions or need a quotation please leave us a message here:

Mark3D UK Ltd Romsley Point Farley Lane, Romsley, Halesowen,B62 0LG

Phone: +44 121 661 1151 Freephone: 0800 193 3650 E-Mail: printstronger@mark3d.co.uk

To contact us, please fill in our secure form.