Our customer Hockley Ltd specialises in the design and manufacture of composite tools, production and assembly tools, jigs/fixtures and a wide range of associated products for the automotive and aerospace industries.

Backed by a forward-thinking board who believe in investment, the group has made several strategic purchases in the last 18 months. “We have a commitment to our customers to deliver the right solution to meet their needs in a prompt and cost-effective manner. We decided to see if 3D printing ‘for engineers’ had come of age yet” explains Ian Eaves and continues: “After a while spent researching the sector we took the decision to increase our design and production capability with the introduction of some state of the art additive manufacturing technology. Our aim is to open new markets and of course serve existing ones better”.

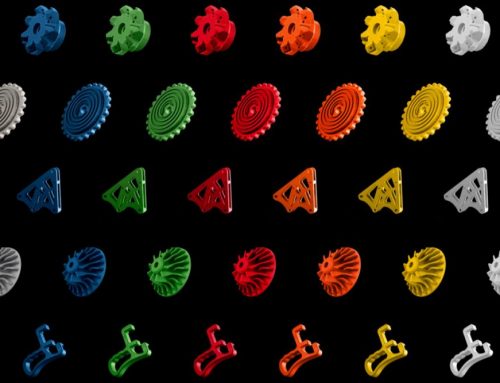

“3D printing is a fast and cost-effective way of doing this. We can now deliver solutions to the technical challenges we’re presented with in a short space of time – we used to wait for machining capacity to be made available to us. The other thing we wanted to achieve with the addition of a 3D printer was to allow us enough flexibility to produce low-volume production items too. If we could find a machine capable of providing good quality parts, which were tough and capable of being used every day without failing, it would be a major bonus!”

Benefits of additive manufacturing for Hockley Pattern:

Request a demo!

Feel the strength of 3D printed parts for yourself.

[…] Read the whole Case Study from Hockley! […]