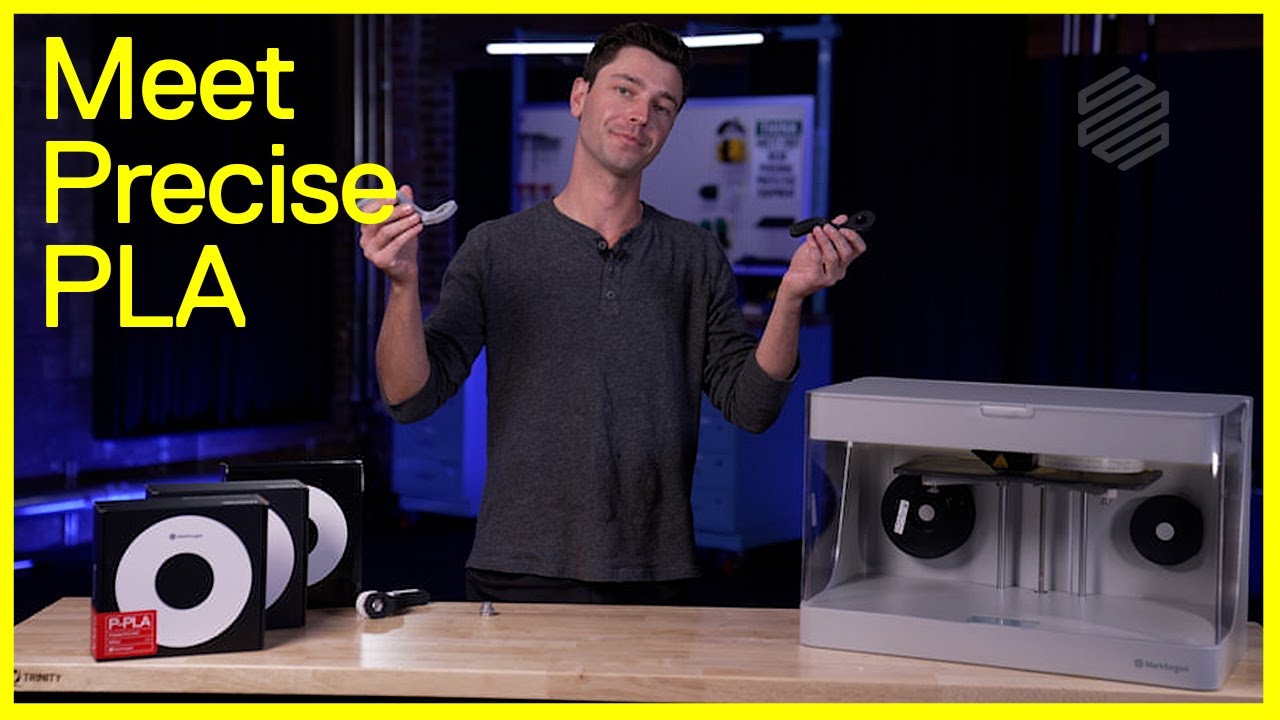

We are excited to announce the addition of Precise PLA to our material portfolio! Now it’s even easier to create prototypes, develop custom tooling and manufacture parts for end users – all on one platform.

What is Precise PLA?

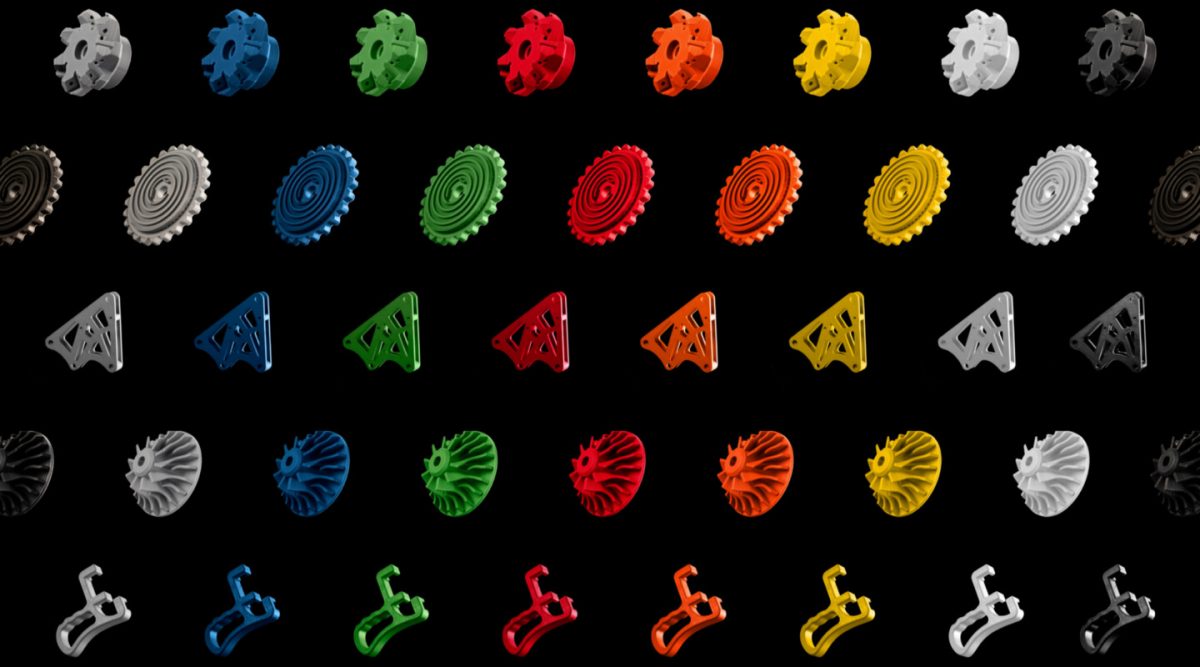

Precise PLA is Markforged’s special version of one of the most common prototyping materials in the additive manufacturing industry, polylactic acid (PLA). Markforged will offer Precise PLA in eight colours – yellow, red, green, blue, orange, black, white and grey.

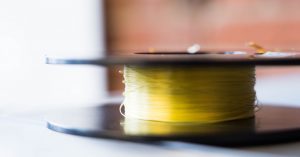

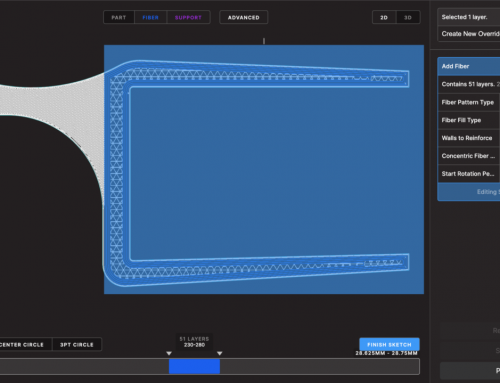

The Digital Forge has been calibrated with changes in the Eiger software to print Precise PLA with excellent quality and repeatability. Priced at £50 per 600cc spool, Precise PLA is now a cost effective option for evaluating designs with the Digital Forge.

When Should I use Precise PLA instead of Onyx™ or Continuous Filament?

We recommend Precise PLA as a more cost-effective option for prototyping, fit testing, or other applications that don’t require the enhanced mechanical properties of onyx and/or continuous filaments. In addition, the different colours can improve the usability and safety of tools and fixtures in the workshop as they facilitate communication about colour codes.

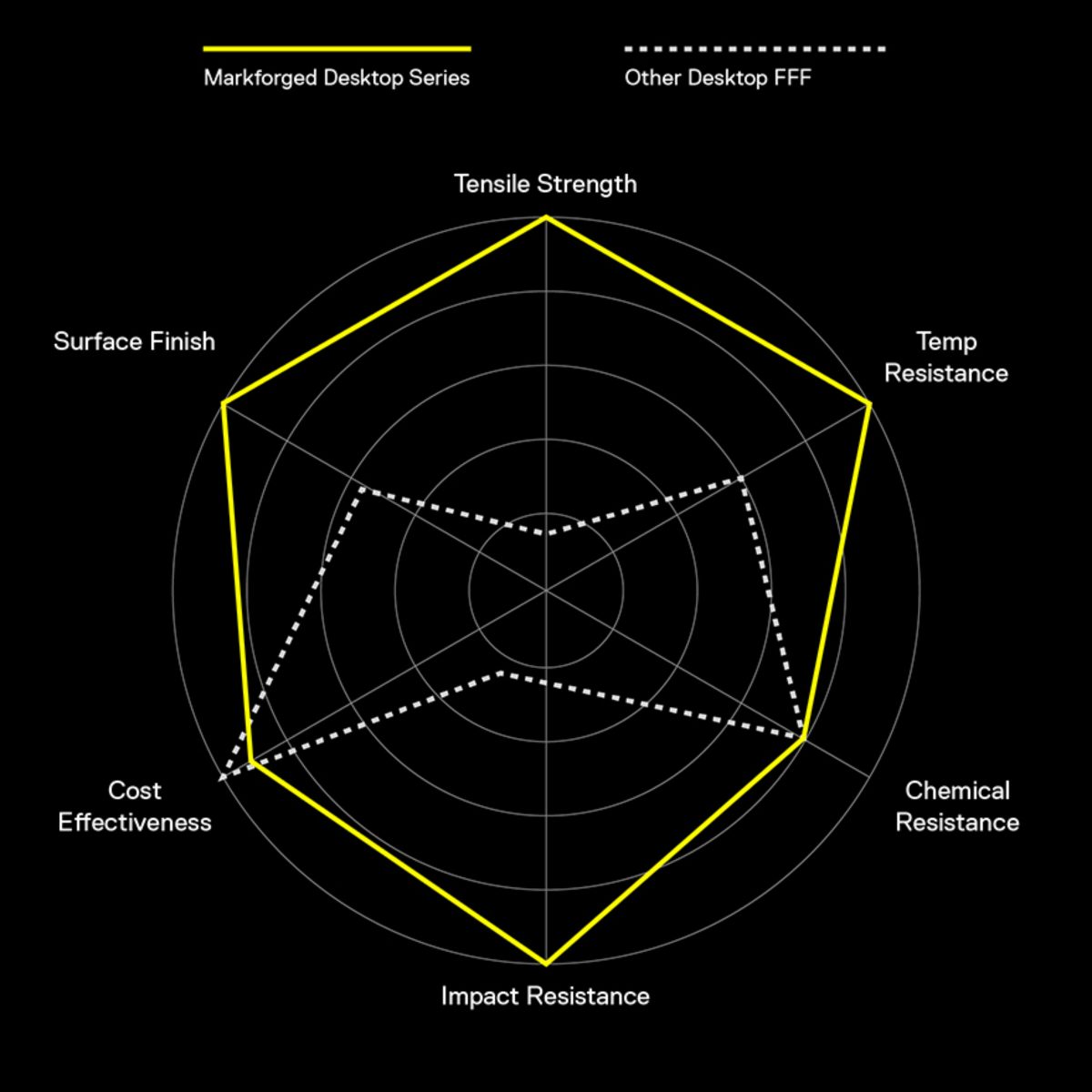

PLA is not compatible with continuous fibers. So, as a rule of thumb, if you need your part to be stronger or more impact or heat resistant than your typical plastic, we recommend onyx and the appropriate continuous filament. For more information on the many applications that are possible with continuous fibers, read this guide. We anticipate that many engineers and designers will first prototype from Precise PLA and then move on to the production version, where Onyx is reinforced with continuous fibers.

Precision PLA: Prototyping Plastic the Markforged Way

Our engineers and material scientists attach great importance to quality. When we set out to create a more affordable plastic for prototyping, we wanted to offer the same print quality, reliability, and ease of use that our users have come to know and love from Onyx.

Zero Tolerance LLC, an injection molding and machine shop that specializes in helping manufacturers take their products from concept to production, was an early tester of Precise PLA.

Steve Michon, President and CEO, reports on his prints with the new material:

“When using other 3D printers and PLA materials, the results were not as precise as required, even after multiple iterations. Printing parts of the size and quality we need, with the functionality we need, and at a competitive price is critical to our business.”

“Once design validation is complete with Precise PLA, we move onto production with Markforged’s Onyx material to test functionality, followed by printing with continuous carbon fiber for added security for our final end part.”

— Steve Michon, President and CEO, Zero Tolerance LLC

In addition to prototyping, Zero Tolerance also uses Precise PLA in conjunction with Markforged’s high-strength composites to print fiberglass-reinforced assembly tools with color-coded handles printed in Precise PLA. The colors help the operator quickly identify the right tool for each job, reducing errors and improving efficiency.

“With this new material, we can now use our Markforged printer to deliver excellent results, time and time again, throughout the design and manufacturing process. This is the most reliable additive platform we have ever used. It just works.”

— Steve Michon, President and CEO, Zero Tolerance LLC

Incredibly Versatile. Built for the Entire Product Life Cycle

Historically, Markforged users have used Markforged’s high-quality printers and high-strength materials to produce mission-critical tools and end-use parts. By bringing together low-cost prototyping materials and functional applications into one easy-to-use platform, Markforged now offers users a more streamlined approach to bringing final designs to life.

“A material for cost-effective concept models and prototypes has been a key requirement from Markforged customers. We’ve taken that feedback and tuned our software and printers to print from Precise PLA, giving our users an extra dimension of versatility. We also hope that this update will allow our customers to have a little more fun in the design process with the additional colors. This is just another example of how the Digital Forge is constantly pushing new applications and getting better as we get more data and feedback from our customer base.” Said President and CEO Shai Terem.

Availability, Printer Compatibility and Usage

Precise PLA will be available in our webshop from March 15, 2022. At launch, the new material will be printed on Mark Two (Gen 2) and Onyx Pro (Gen 2) desktop series printers equipped with our latest A3648 extruder. Later this year we also plan to make Precise PLA available on all Industrial series printers with the second generation A3648 extruder. Read this support article if you are not sure which generation your extruder is. As a special maintenance procedure for Precise PLA, you also need to occasionally flush the printhead. So make sure you take a flushing stick with you when you first buy Precise PLA coils.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

![Jet Dragster Racing [Video] with 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Josette-Roach-500x383.png)

![Hollywood Propmaster [Video] 3D Printing with Markforged](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Thingergy-26-scaled-500x383.jpg)

![BattleBots Valkyrie [Video] Using 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/BattleBots-11-500x383.png)

Leave A Comment