17-4 Stainless Steel

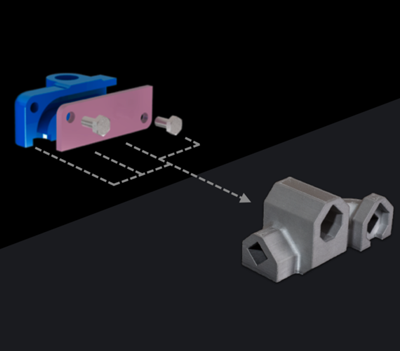

3D metal printing more affordably than ever before.

When should I 3D print with 17-4 Stainless Steel?

17-4 PH Stainless Steel is a hard, stiff, and corrosion-resistant stainless steel. It excels in manufacturing environments and for low-volume parts.

Low-Volume Production

Spare Parts

Complex Geometries

Corrosion-Resistant Parts

Request a demo!

Convince yourself of our 17-4 PH Stainless Steel.

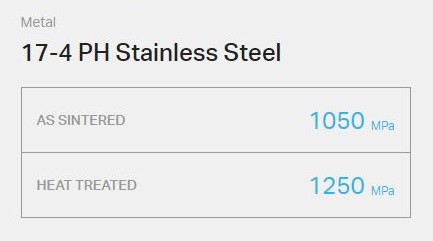

Near wrought strength

3D printed 17-4 PH Stainless Steel exceeds MIM standards and reaches 95% wrought strength under equal heat treatment.

Working with 17-4 PH Stainless Steel

17-4 PH Stainless Steel is best heat treated to maximize strength, hardness or toughness. H900 condition, heating your part to 900F (482C) for four hours, yields the strongest and hardest possible parts. H1150 condition (1150F instead of 900F) can also be used to maximize toughness at the expense of ultimate tensile strength.

Compatible with our Metal X system.

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.