A look behind the scenes: How does metal 3D printing work with Markforged?

How does the process differ from 3D printing with plastic? Which metals can already be produced by additive manufacturing? How does metal 3D printing work without toxic metal dust? What downstream processes are there?

An application engineer from Markforged explains these questions in detail:

Fill out our secure form to watch the free video.

World’s leading businesses are using Markforged 3D printers

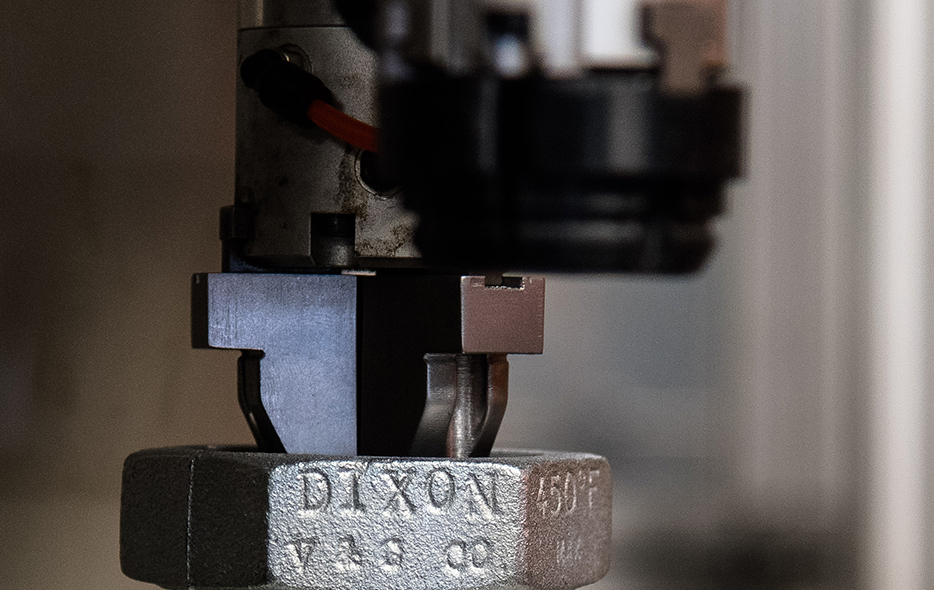

Produce high strength components

Markforged is specialized in 3D printers for high strength applications. The range of metal and composite 3D printers delivers parts in stainless steel, tool steel, copper, carbon fiber, fiberglass, Inconel and more.

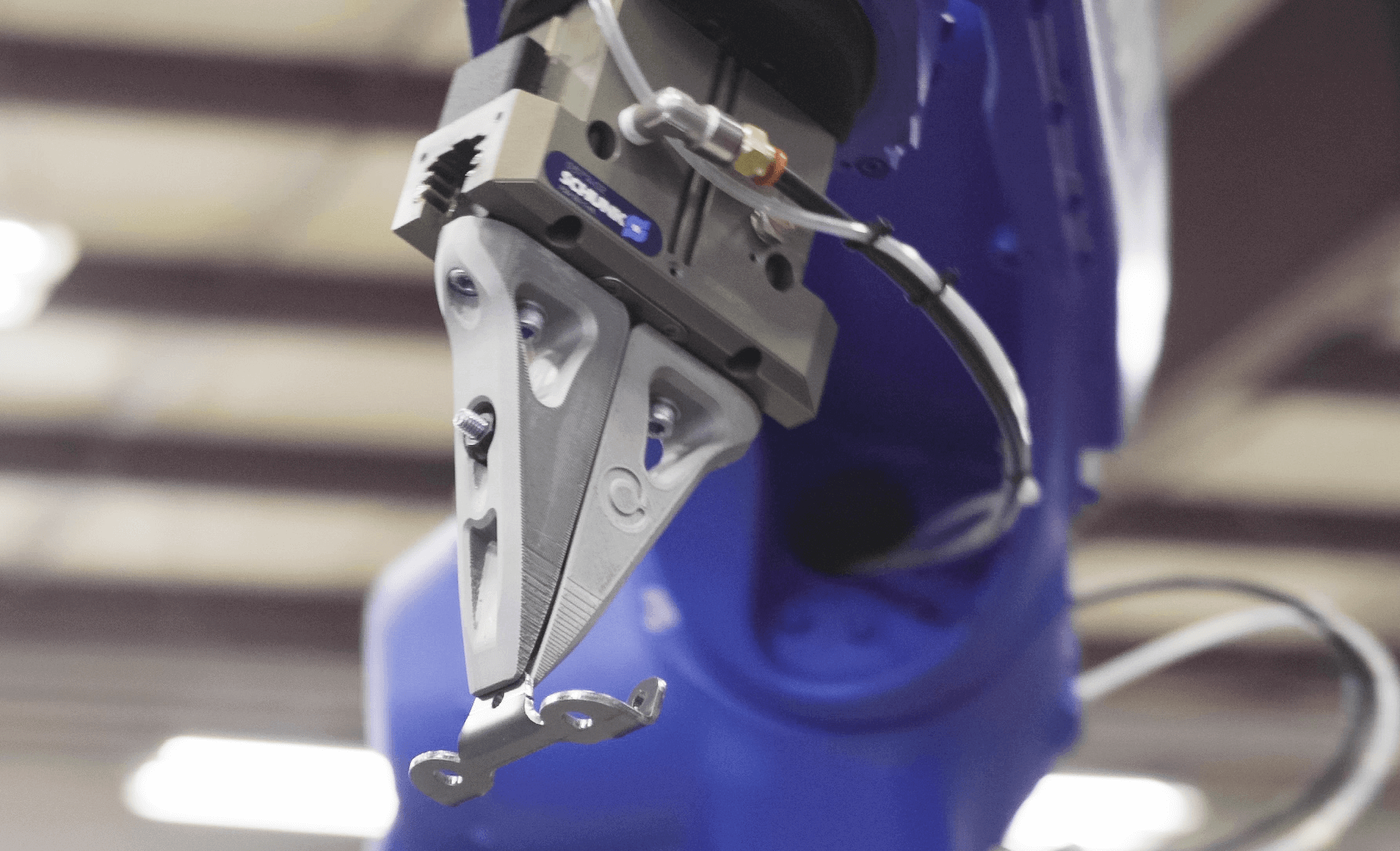

Use the bandwidth of conventional production for revenue-generating parts

Lean Machine now produces 5 times less conventionally manufactured equipment such as tools and fixtures and instead uses Markforged technologies to produce parts that are not possible with other technologies. CNC machine operators now spend all day concentrating exclusively on production work, and are less involved in creating equipment.

Minimize lead times from prototype to finished part

With your own Markforged 3D printer, you have control over when your parts are manufactured and reduce the risk of unexpected delays in the supply chain.

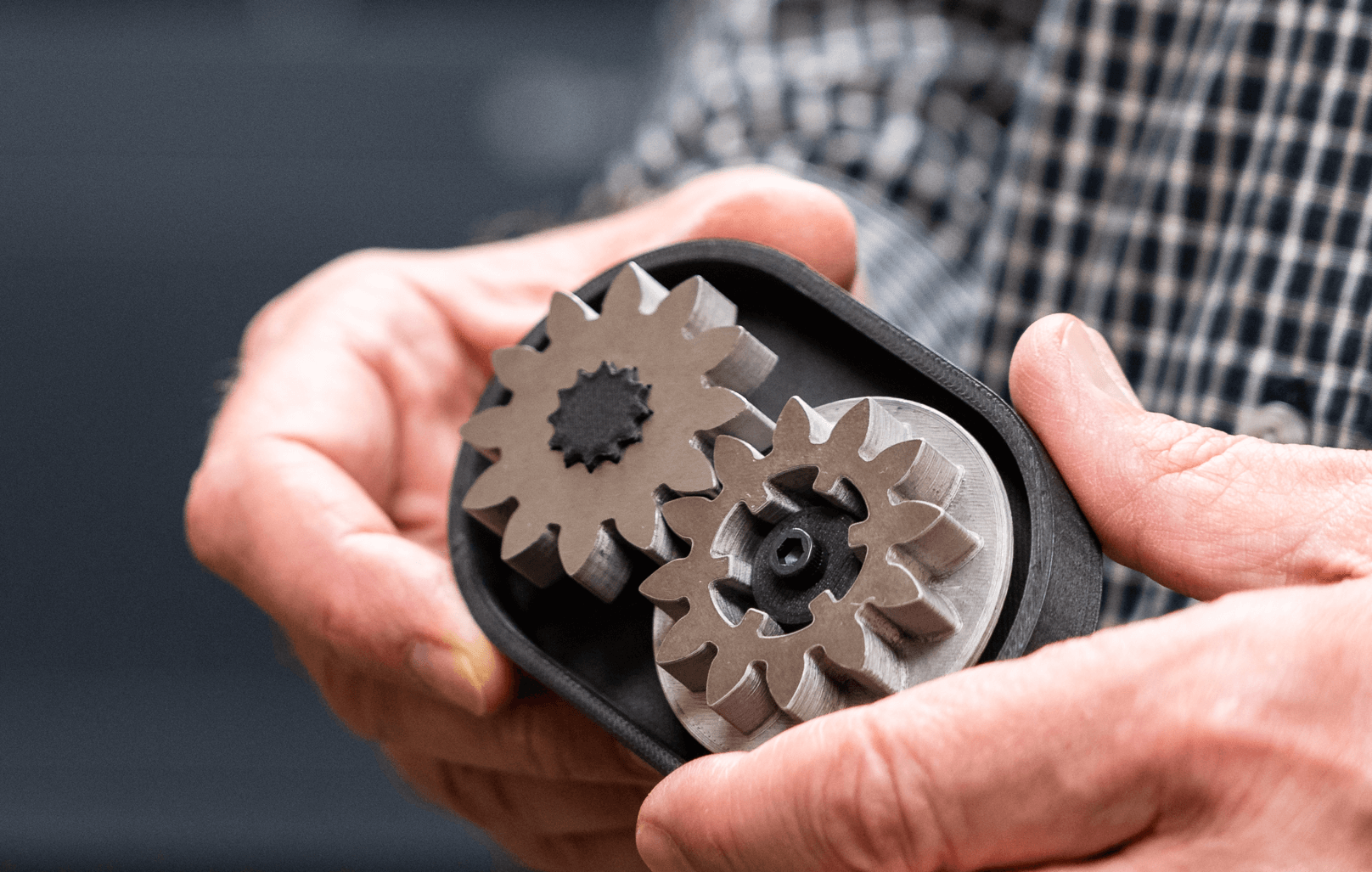

3D printing gives you full design freedom to produce complex geometries

With Markforged 3D printers, you can produce parts that were previously too complex or costly to manufacture. Think new! You have almost no limits in the design of your parts!