What is Simulation doing?

Verify parts meet performance requirements and optimize manufacturing efficiencies before the part is printed.

Integrating 3D printing into tooling and end-use applications requires absolute confidence in part strength. Traditionally, this has required lengthy test cycles between design, print and fracture, or expensive analysis software.

Markforged’s simulation takes the guesswork out of 3D printing by incorporating virtual testing and time/cost optimization into our familiar slice-and-print workflow.

Simulation in Eiger

Validate part performance and optimize print settings to ensure the part meets performance requirements and maximize manufacturing efficiencies.

Easy to use, fast and accurate.

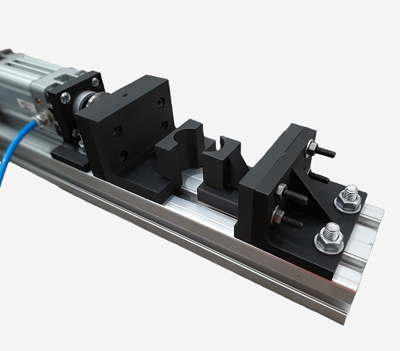

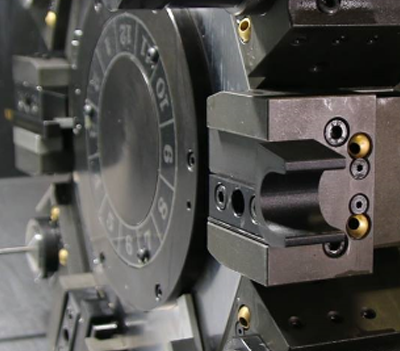

Check component performance

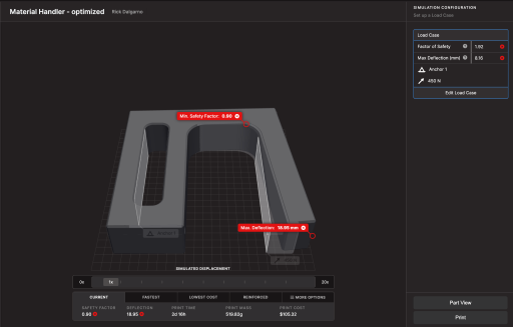

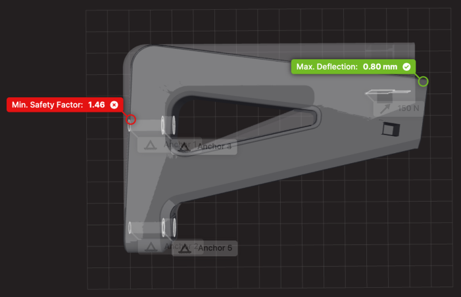

Simulate the strength and stiffness of a part printed with a custom print configuration.

Simple, intuitive feedback showing part strength, part stiffness, and a visualization of part deformation under load.

Optimizing the print settings

Automatically configure print settings to meet performance requirements and minimize print time and material consumption.

Several solutions with and without continuous fiber are generated.

Advantages with simulation

Verify parts meet performance requirements and optimize manufacturing efficiencies before the part is printed.

Integrating 3D printing into tooling and end-use applications requires absolute confidence in part strength. Traditionally, this has required lengthy test cycles between design, print and fracture, or expensive analysis software.

Markforged’s simulation takes the guesswork out of 3D printing by incorporating virtual testing and time/cost optimization into our familiar slice-and-print workflow.

30-50%

Saving of printing time and material per part

50-90%

Reduction of iteration cycles

30-50%

Increase in throughput per printer

Markforged Simulation Frequently Asked Questions (FAQs)

Learn more about the applications with the Desktop Series!

How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.