Tech tip: Setting different settings packages within a component

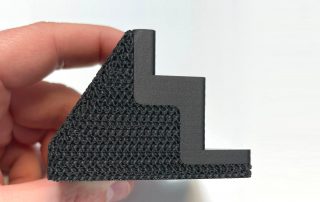

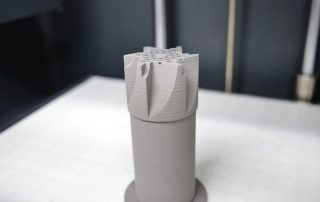

Tech tip: Setting different settings packages within a component Reasons & Advantages Composition of a setting package How do I proceed? (step-by-step instructions) The final component Reasons & Advantages When it comes to 3D printing, it is always necessary to optimize the settings for the production of [...]