Markforged Industrial Carbon Fiber Printer Gets 2x Faster

Leading provider of industrial 3D printers dramatically increases the print speed without losing the company’s high-quality surface finish

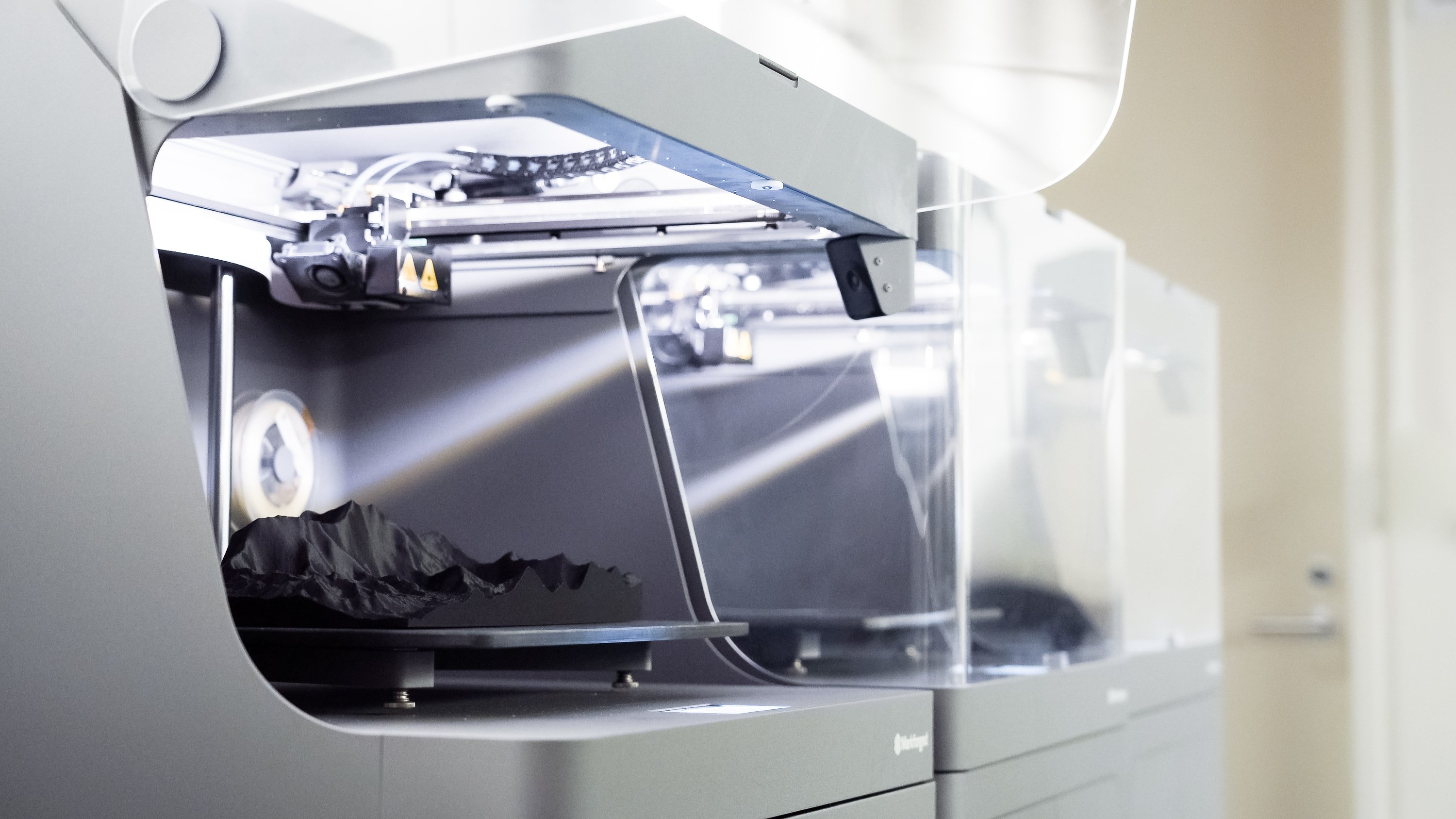

Markforged the leading manufacturer of metal and carbon fiber 3D printers, today announced Turbo Print for the X7 3D printer at Formnext. The new feature doubles the print speed of the industrial printers without sacrificing Markforged’s best-in-class surface finish, giving customers the ability to replace parts faster, take on more jobs, and see a rapid return on investment.

“Twice as fast means twice as productive,” said Michael Ott, Head of Production Innovation at Siemens Healthineers in Germany. “We received our Markforged X7 in September, and have been thrilled with the results so far. The surface finish is unparalleled, and we can customize our parts to be exceptionally strong and ultra-lightweight. Now with this new feature, we’ll be able to make parts in half the time.”

Turbo Print will be released on December 16 and is compatible with all second-generation X7 3D printers. Shipping since June, the second-generation printers further enhanced the quality and reliability of the carbon fiber 3D printer lineup and enables the release of new features like Turbo Print.

“For many vendors in the additive manufacturing space, high-speed printing kills part quality,” said Greg Mark, CEO and Founder of Markforged. “Our customers value the beautiful surface quality and mechanical properties of their 3D printed parts, so we developed a way to maintain our high standard at a much faster pace. Now customers will be able to move from digital design to functional parts twice as fast, opening the door for rapid development and faster time to market.”

Markforged 3D printers have transformed manufacturing by creating strong, durable, functional products of all kinds of applications in automotive, oil and gas, aerospace, and harsh environments. With tens of thousands of users in more than 50 countries, demand has exploded for Markforged’s metal and carbon fiber 3D printers and will continue to grow as new features like Turbo Print are released. With these new updates, we continue to magnify the value of additive manufacturing.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

![Jet Dragster Racing [Video] with 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Josette-Roach-500x383.png)

![Hollywood Propmaster [Video] 3D Printing with Markforged](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Thingergy-26-scaled-500x383.jpg)

![BattleBots Valkyrie [Video] Using 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/BattleBots-11-500x383.png)

Woah, I never knew this existing. It’s definitely awesome to be able to print some form of carbon fiber.