3D Printed BattleBots [Video] Valkyrie vs Quantum

Watch two 3D printed BattleBots go toe to toe in this 3:30 video!

Both of these BattleBots were created with Markforged technology. The stealth jet inspired Valkyrie sports a vicious 65 pound spinning blade weapon that can reach 250mph, and in this video battles Quantum, a crushing robot with a bite force of more than 15,000kg designed in the UK by Robo Challenge.

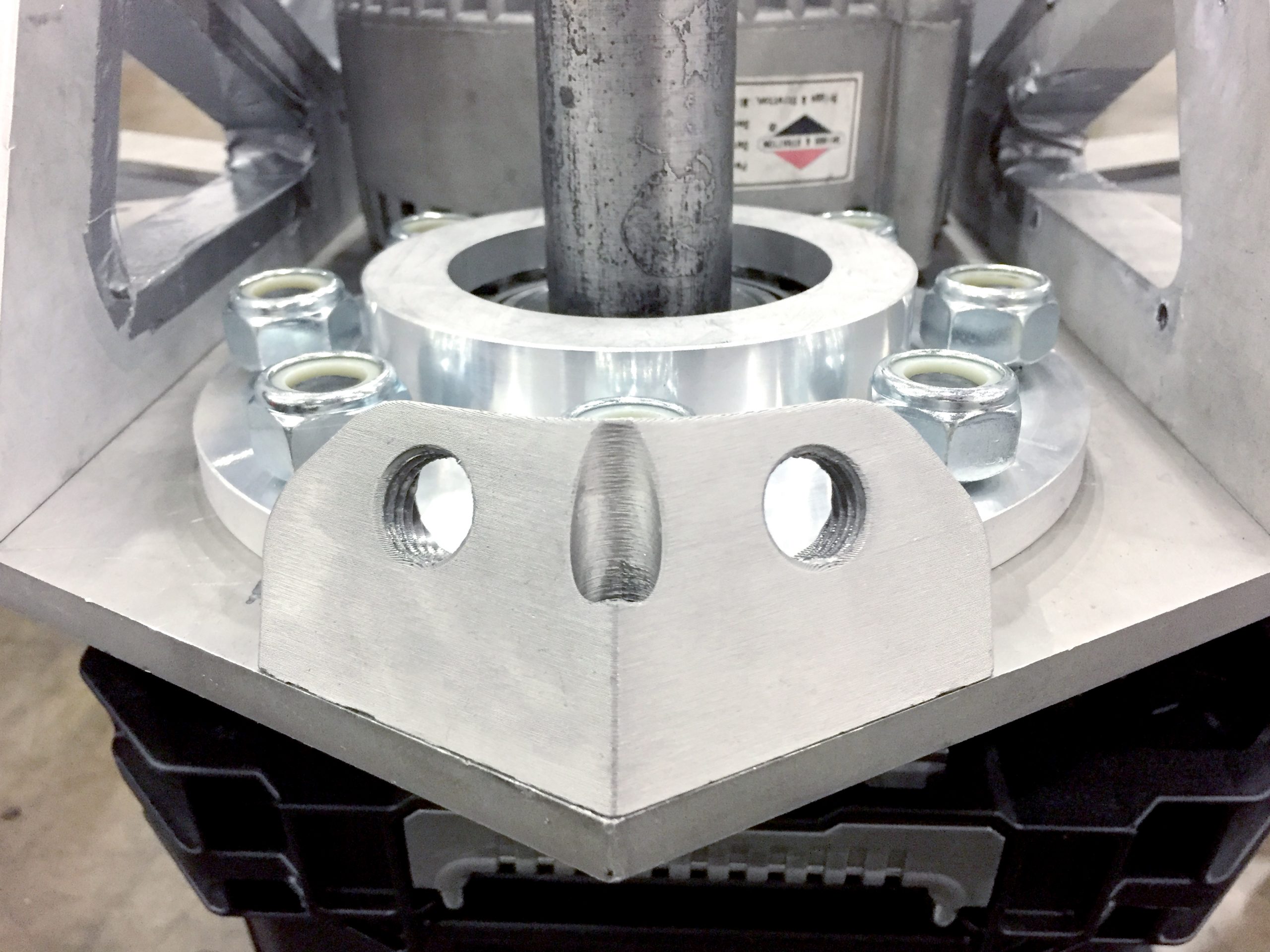

Both teams used 3D printed parts extensively in their designs; team Valkyrie creating composite jigs, component casings and structural elements, and even using the Markforged Metal X to print the complex geometry of their front armour bracket. Team Quantum have similarly used Markforged carbon fibre reinforced 3D printed composite parts; drastically increasing the survivability of their robot by replacing aluminium ribs that were prone to snapping with stronger, more flexible composites.

Watch the video to see these two beastly machines battle in the arena!

Get a demo 3D printed part for your workshop

Both of these fighting robot teams have taken full advantage of the rapid manufacturing abilities that come with 3D printing, and the mechanical strength offered by Markforged’s materials and continuous fibre reinforcement.

It just goes to show that 3D printing isn’t just for prototyping; it’s a fully fledged manufacturing technology that is tough enough for functional end use parts in even the most extreme of conditions.

Markforged is strong enough for the arena – stronger than aluminium – and strong enough for your industrial applications.

Let us prove our strength to you by requesting a demo part with the form on this page, and we’ll print a part tailored to your application for you to test in your own workshop.

Learn more about the applications with the MarkTwo!

Which continuous fibers are suitable for which applications? How do I properly design for filament 3D printing? What do users say about this and where can I find more information? – You are right here! We have listed some information options that will take you straight to the right answers.

![Jet Dragster Racing [Video] with 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Josette-Roach-500x383.png)

Leave A Comment