Request a Sample Part!

Feel the strength of continuous fibre for yourself.

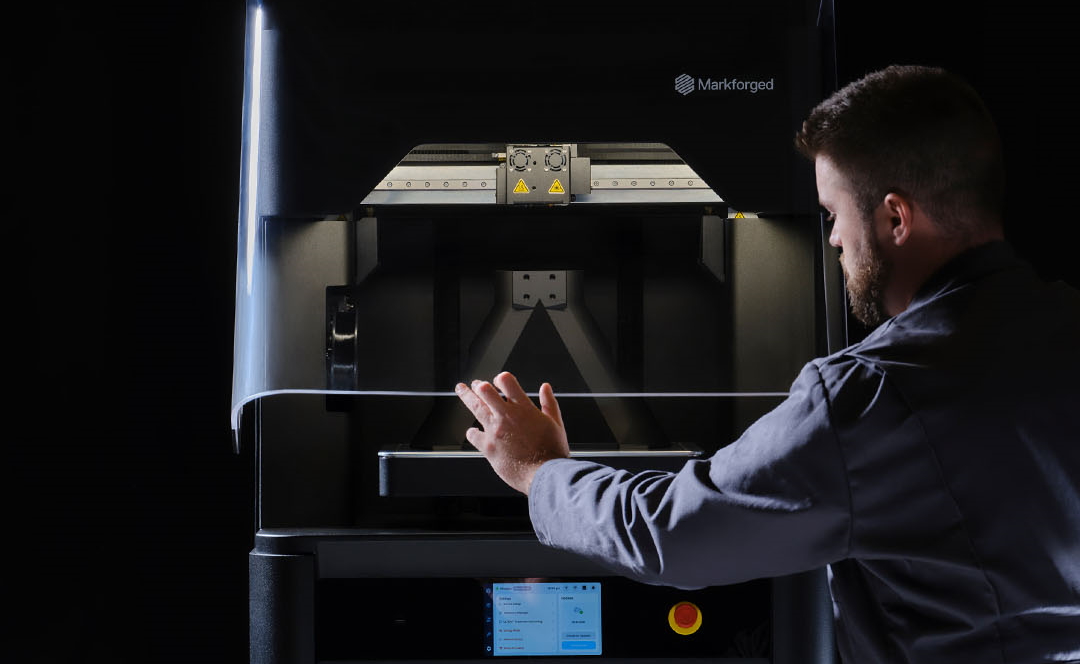

The Markforged FX10 – 5th Generation Industrial 3D Printer

The FX10 is Markforged’s next-generation industrial composite 3D printer – the result of years of engineering innovation and technological advancement. Building on the success of the Markforged X7, its sole purpose is to deliver strong, precise parts every time you print.

The FX10 features a new modular architecture designed for upgradeability and printhead-mounted optical sensors that inspect part dimensional accuracy and device health and performance. It utilizes automatic calibration and material changing, resulting in a simple, easy, low-touch user experience that meets the needs of operators.

Create mechanically resilient components on demand

The Markforged FX10 can print continuous carbon fibre reinforced components for a wide range of production applications. This helps manufacturers accelerate time to market, reduce manufacturing and inventory costs, and reduce the risk of production downtime.

Print the right component, every time

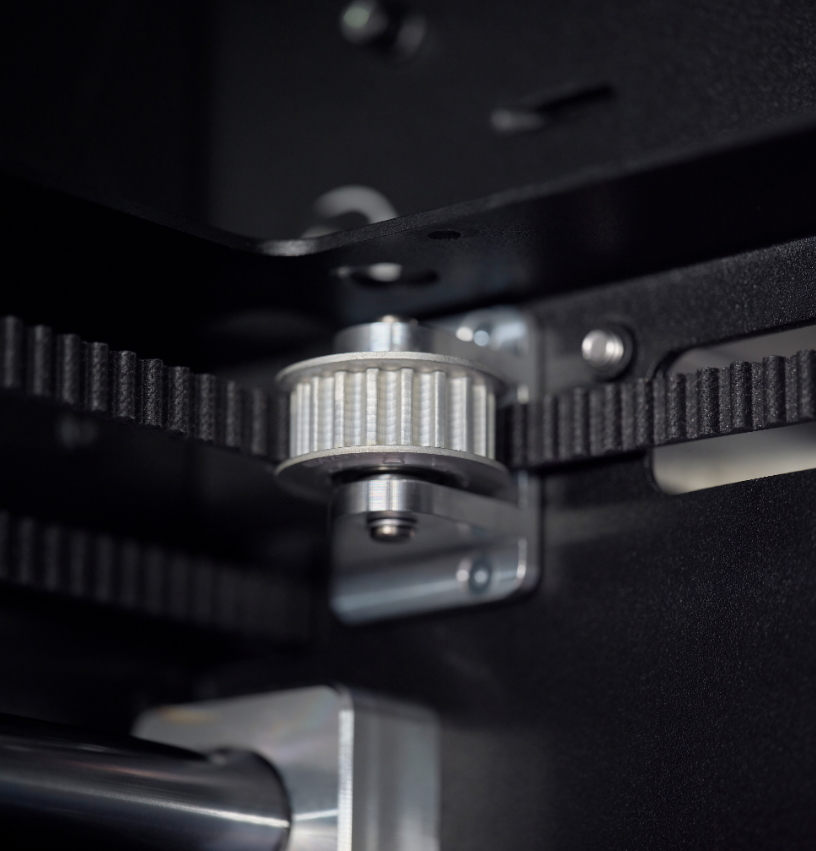

Every aspect of FX10 – from its motion system to the software that controls it – is designed to reliably deliver precise, stable parts. Supported by simulation and inspection software, the FX10 can produce tested parts that meet strict requirements on the factory floor.

Achieve ROI quickly, then upscale

The FX10 works with Digital Forge: Markforged’s additive platform, which offers intuitive device and desktop software, training and integrated costing. You can generate ROI from day one and easily expand to additional teams, machines and facilities.

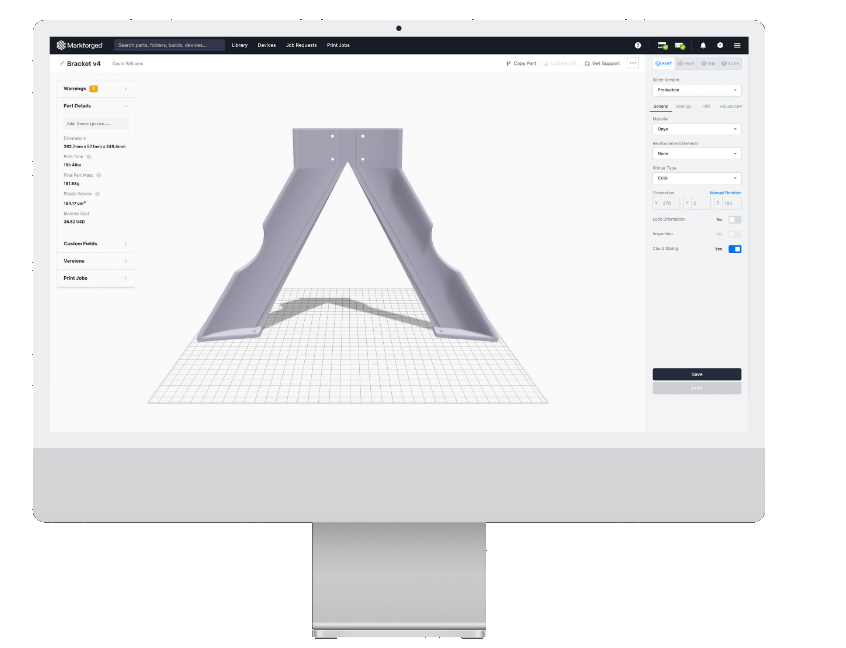

The Digital Forge: Powered by Software

Markforged offers a simple, intelligent, and scalable additive manufacturing platform that fits seamlessly into your manufacturing operations. Our Eiger™ software is designed to scale, providing a unified user experience, digital parts storage and fleet management across the entire Markforged portfolio, including the FX10

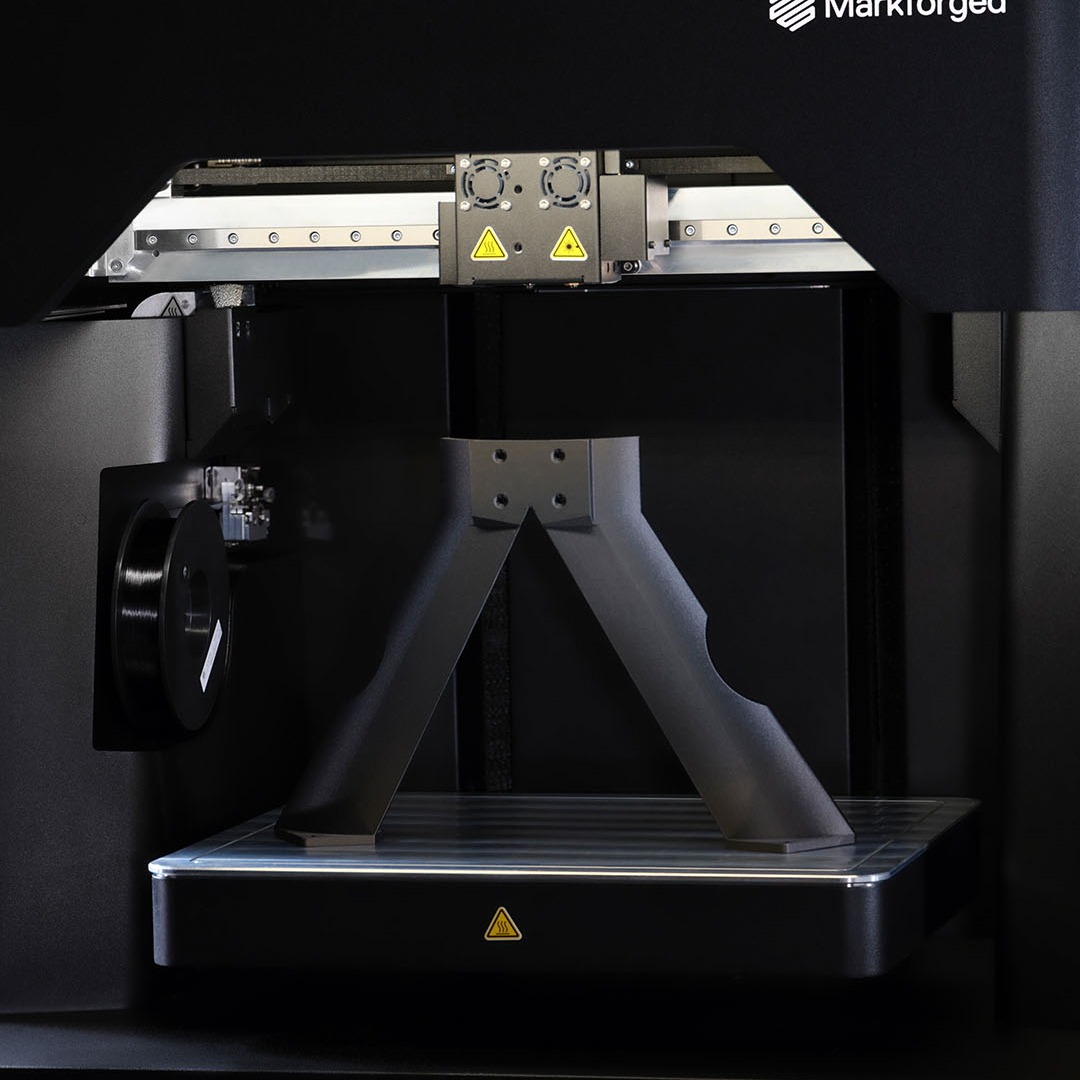

Image Processing Module and Laser Micrometer*

The FX10 has two optical sensors mounted on the print head. The Laser Micrometer Inspector, which checks layer dimensions for print validation and machine calibration, and the new Vision Module which uses detailed images to scan parts and optimize printer performance.

*The Image Processing Module will not be delivered with the first FX10 devices, but will be sent as a free upgrade package shortly after market launch.

Vacuum Sealed Print Bed

The Markforged FX10 features a large build chamber that can be heated to 60°C, ideal for printing high-quality parts at rapid speeds. The vacuum-sealed aluminium print bed is also heated, and has precision grooves that are scanned to the micrometre by the laser for calibration.

Modern Material Storage with Automatic Changeover

An internal material cabinet stores four spools in individually sealed compartments and supports automatic material changing and rapid loading of spools, minimising the need for user intervention.

The Markforged FX10 increases the profitability and productivity of your manufacturing

| Technical Data | Markforged FX10 |

|---|---|

| Build Volume | 375 x 300 x 300 mm |

| Z-layer Height | 125 – 250 μm |

| Build Chamber | Heated to 60 °C |

| Materials | Engineering Thermoplastics: Onyx™ Continuous fibres: carbon fibre |

| Power | 230 V |

| Weight | 109 Kg |

| Footprint | 760 x 640 x 1200mm |