H13 Tool Steel

Tool Steel optimized for high-temperature and high-wear applications.

When should I 3D print H13 Tool Steel?

H13 Tool Steel works excellently in high temperature and can withstand drastic cooling. This, coupled with abrasion resistance and machinability, makes it ideal for high-temperature tooling and wear-resistance pieces.

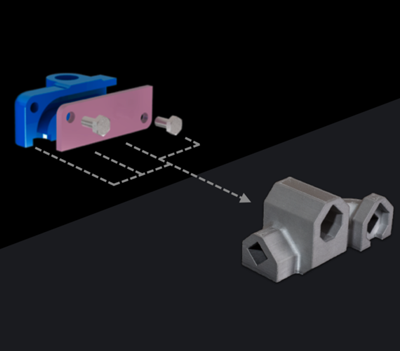

Forming Tooling

Wear-Resistant Inserts

Dies and Punches

High-Temperature Tooling

Request a demo!

Convince yourself of our H13 Tool Steel.

Working with H13 Tool Steel

Markforged H13 Tool Steel gets harder, stronger, and tougher when heat treated. We recommend air quenching at 1010C (1850F) and double tempering at 600C (1110F). For improved hardness at the expense of part toughness, you can double temper at a lower temperature (500-550C, 930–1022F).

Compatible with our Metal X system.

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.