Guhring UK – Reduction of lead times through additive manufacturing

“As we started looking at supplying smaller volume customers, it became an issue,” says Alan Pearce, PCD Production Supervisor at Guhring UK.

Each piece of special tooling Guhring UK makes needs to first be designed and approved by the customer. Depending on the size and complexity of the component, special tooling can take up to eight weeks to design, test, and manufacture in-house — and the work can’t even start on the tool until the design is approved. Smaller manufacturers with less volume can’t justify the costs or lead time for special tools.

This led the company to look into additive manufacturing as an option to open up new revenue streams, reduce lead times for existing ones, and manage timelines for smaller customers.

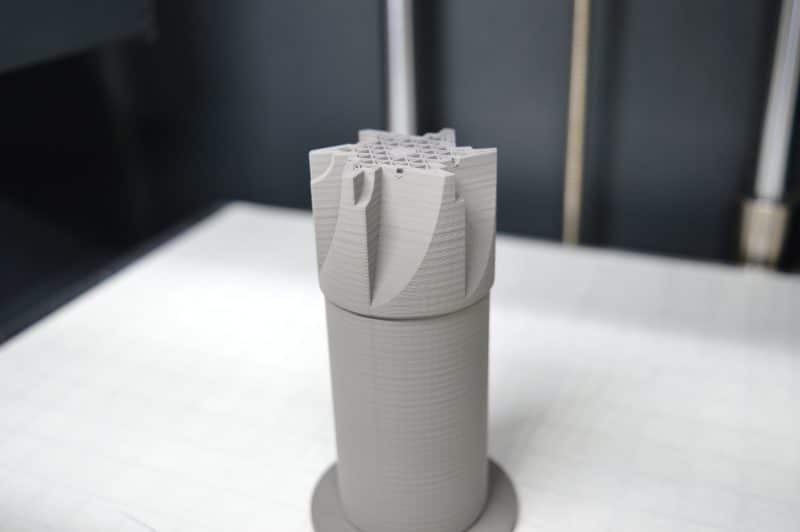

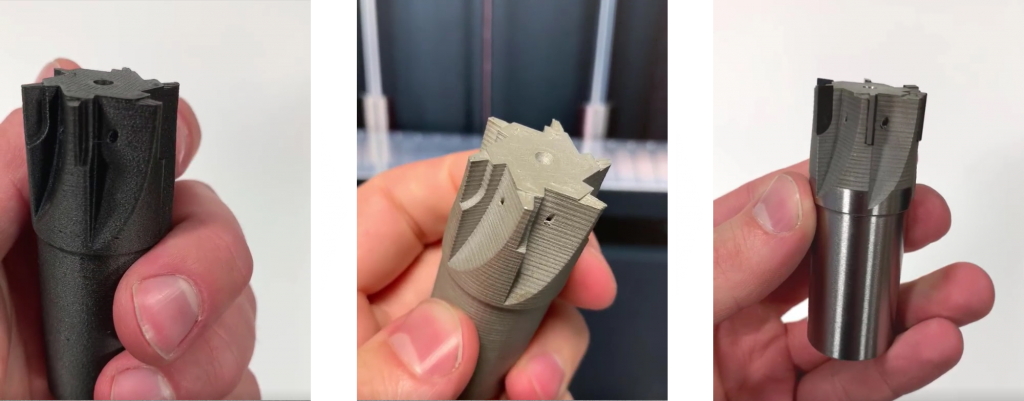

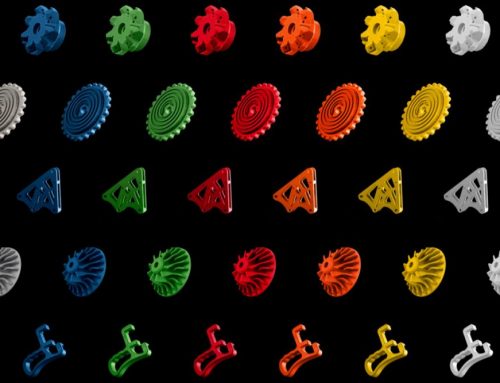

Thanks to Markforged 3D printers, Guhring can present a 3D printed prototype made of onyx to the customer at the first appointment, just a few days later. On this basis, the final cutting tool is then printed on the Markforged Metal X 3D printer using the H13 tool steel.

Learn everything about the Process and applications in our in-depth case study. (click)

See where additive manufacturing fits in a subtractive world at Guhring UK’s ‘Factory of the Future’

The Guhring Group is a world class manufacturer of precision cutting tools and allied tooling for the engineering & manufacturing industries. With over 8000 employees worldwide and a product range of 1620 products (in 44,000 sizes) they are renowned for being leaders in their field.

Request a demo!

Feel the strength of continuous fiber for yourself.

Leave A Comment