Before buying a 3d printer it is important to establish what you need from it. Some 3d printers are known for their ease of use and user friendliness, others for producing beautiful parts with a great surface finish, and others still for the strength of the parts they can print. Luckily, buying a Markforged 3D Printer is a great choice if you are looking for a work-horse that can produce super-strong parts with a great surface finish, easily and without much in the way of 3d printing experience.

We have put together a few key points that are useful to know before you buy a Markforged 3D Printer.

What Size Can They Print?

The Markforged 3D Printers have a range of sizes they are capable of printing, depending on your needs and your budget.

The Onyx One, Onyx Pro and Mark Two 3D Printers, known as the Desktop Series, can print up to 320 x 154 x 132mm in size.

The X3, X5 and X7 3D Printers, known as the Industrial series, can print up to 330 x 270 x 200mm in size.

The FX20 3D Printer can print up to 525 x 400 x 400mm in size.

What materials can they print?

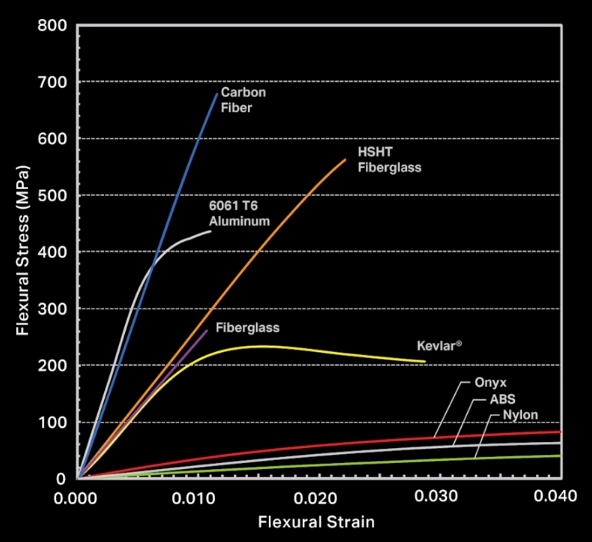

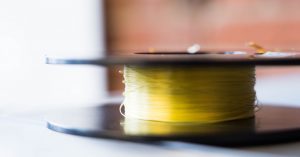

Markforged have a proprietary material called Onyx. This material is Nylon-6, blended with carbon fibre, which is about 20% stronger than ABS. Some Markforged 3d printers allow the inlaying of continuous fibres, that reinforce and strengthen the printed parts even further.

Onyx is by far the most widely used, and versatile, material at the moment. Markforged are continuing to develop and release materials that extend the applications for printers. This year we saw the release of Precise PLA, a special version of the popular PLA material for quality printing on the Markforged machines, giving users a low cost alternative for prototyping and in 8 different colours.

The Industrial Series of Markforged 3D Printers have access to specialist materials as well, such as Onyx FR and Onyx ESD, a v0 rated flame retardant and ESD compliant material respectively.

The all new FX20 has taken the Markforged portfolio into high-temperature engineering polymers, namely ULTEM™ 9085. An extremely resistant thermoplastic with excellent flame, smoke and toxicity properties (FST) widely used in aerospace and automotive.

Its important to consider what materials you will need, or may benefit from, before you buy a Markforged printer.

What does machine maintenance involve?

Before you buy a Markforged, or any, 3D printer its important to understand the maintenance required. Typically extrusion based 3D printers, which the Markforged FFF technology is based on, are of the most simplest machines to maintain. Almost all parts on the Markforged machines are self-fit, allowing regular maintenance to be untaken in a short time and ensuring the printer is always running at its best. Regular maintenance is limited with only a few wearable parts needing changing, such as nozzles and tubes.

Routine maintenance is key to keeping 3D printers running at its best. Markforged offer ‘success plans’ with their printers making it easy and cost-effective to maintain machines. Wearable parts are covered and replaced on a maintenance schedule, so they are not just replaced when the wear, you’re always kept printing at the best quality. Parts are also covered for damage, if the unexpected happens.

What applications can they be used for?

We are seeing Markforged printers being used for a wide variety of applications, from tooling in large automotive/aerospace production lines, to bespoke brackets for cameras on film sets, to end-use production cutting tools. The possibilities are vast.

We’re not saying everything is possible, all 3D printing technology have applications they suit and do not suit. For example, you wouldn’t use a Markforged printer for fine artist detail or high volume production, but where they excel is strong, robust, reliable, function parts.

Read through the customer stories on our website to see more application examples.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

![Jet Dragster Racing [Video] with 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Josette-Roach-500x383.png)

![Hollywood Propmaster [Video] 3D Printing with Markforged](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Thingergy-26-scaled-500x383.jpg)

![BattleBots Valkyrie [Video] Using 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/BattleBots-11-500x383.png)

Leave A Comment