Onyx

What is Onyx?

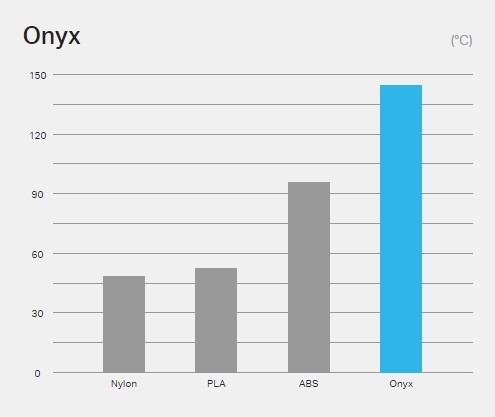

Nylon mixed with chopped carbon fibres provides a high strength thermoplastic with excellent heat resistance, surface finish and chemical resistance.

When should I 3D print with Onyx?

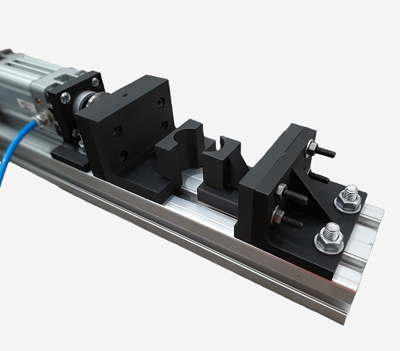

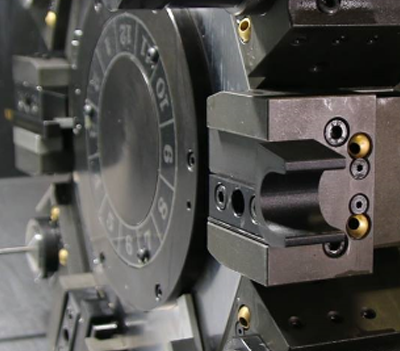

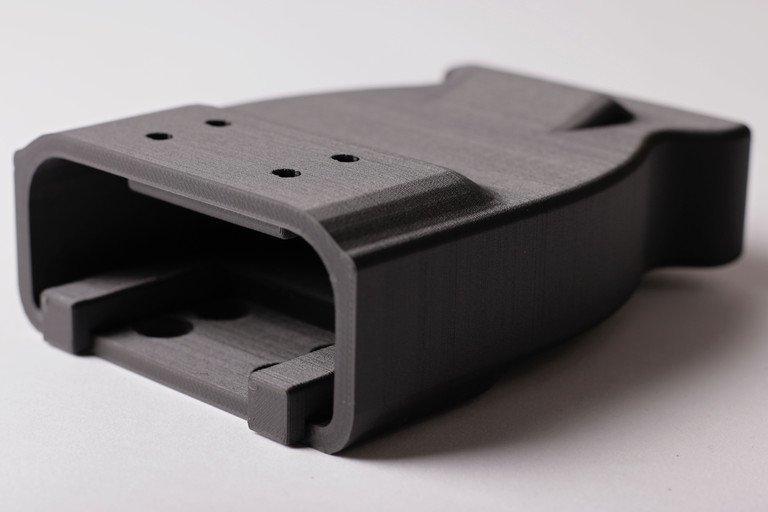

Onyx is used as a thermoplastic matrix for Markforged’s composite parts. It can be printed on its own or reinforced with one of the continuous fibres to achieve a strength comparable to aluminium. Use Onyx for everything from tools and fixtures to finished parts.

Strong, wear-resistant tools

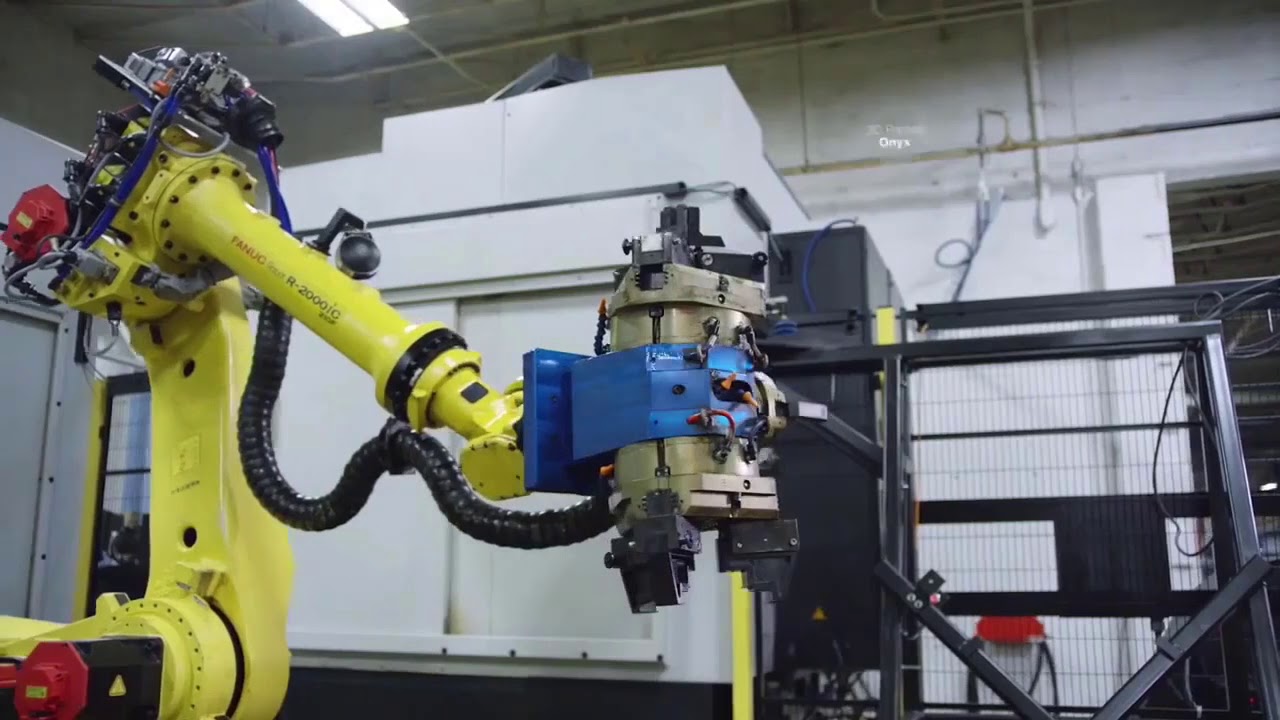

Dixon Valve is a manufacturer of valves and fittings and produces robot grippers in onyx to grip different threaded parts better. Onyx is much more wear resistant than ABS, so the grippers have a longer lifetime.

“With Onyx, we have been able to reduce the weight of our robots and thus grip even larger and heavier parts.”

Rodney Everett, Automation Technician

Benefits of Onyx

Developed for engineers Onyx has the load capacity of nylon/PA6, the stiffness of fibre reinforced plastic and a heat deflection temperature of 145°C. Markforged Onyx is the perfect 3D printing material for all industrial applications.

You get exactly the parts you have constructed. The added micro-carbon fiber makes it possible to produce more durable components with much higher surface stability.

Reduce your rework effort Due to its black, matt colour, Onyx is perfectly suited for ready-to-install components. You can use your manufactured components directly from the building platform – without chemical or mechanical rework.

The Markforged Material Advantage Onyx can be further reinforced with continuous fibers such as carbon, Kevlar® and glass fiber. Onyx can also be printed without fiber. The quality of the components goes far beyond what you already know from conventional 3D printers.

Request a demo!

Feel the strength of continuous fiber for yourself.

The Onyx Filament can be used in all current Markforged 3D printers!

Note: Printing large quantities of onyx changes the chemical composition of the print head in a way that is tailored to onyx printing. You are, of course, free to use one coil of onyx and one coil of nylon. However, you should choose a material, otherwise the print quality will be affected. If you want to continue using both materials, you should buy a second print head or printer.

FAQ

How strong is Onyx? Onyx has a flexural strength of 81 MPa (11.7 ksi). For more information on Onyx material properties, see the Datasheet.

What is the difference between cut carbon fibres and continuous carbon fibres? Chopped carbon fibre mixed in onyx filament gives it high stiffness and strength. Continuous carbon fibre is a reinforcing fibre that can be printed in long strands, making composite components many times stronger and stiffer than onyx. For further information, please refer to this article

Learn more about the applications with the Desktop Series!

How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.