Customer Spotlight

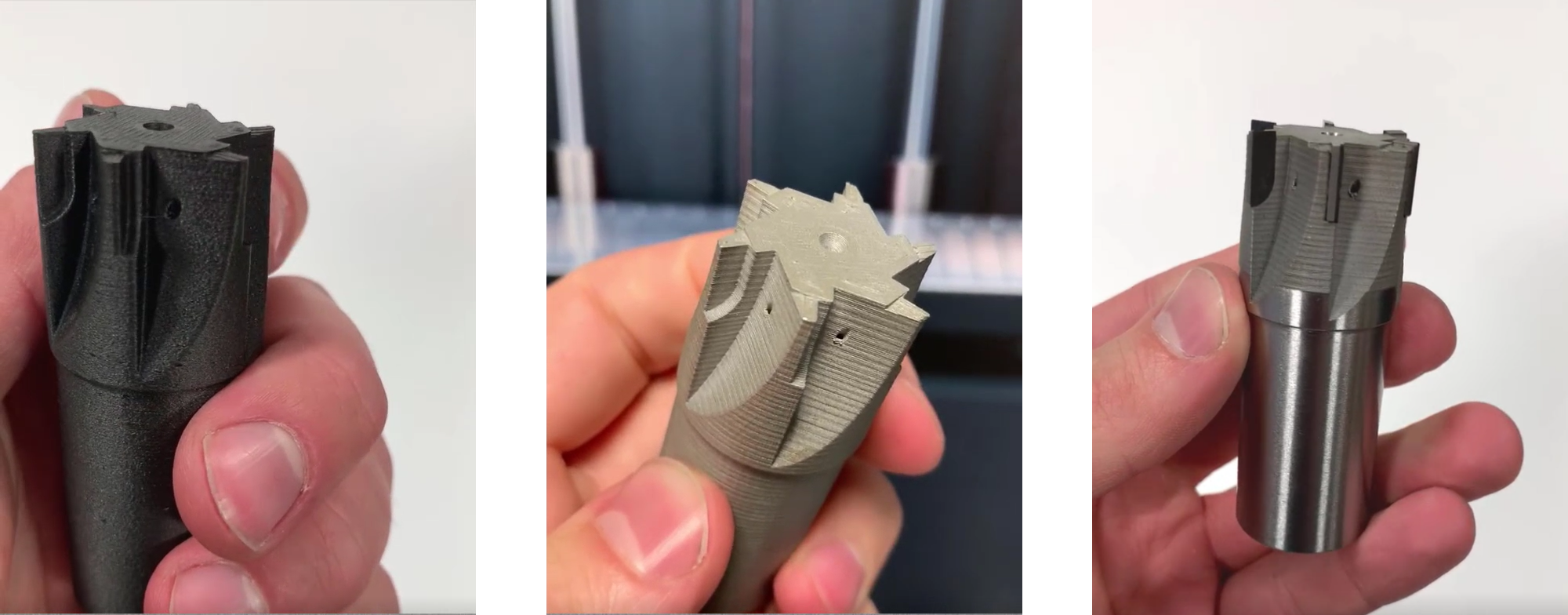

Manufacturing of Cutting Tools at Guhring UK

Watch the full interview

12 Questions for Guhring UK

Daniel Stokes of Mark3D UK spoke to PCD Production Supervisor Alan Pearce at Guhring UK in a “round table chat” about manufacturing of cutting tools with additive manufacturing.

Jump to the question you are interested in:

#1 Introduction

#2 Why did you first look at additive?

#3 Why did you choose Markforged?

#4 What was the first tool?

Visit Guhring!

#5 Have there been any benefits?

#6 What are the lead times?

#7 What is PCD?

#8 What is your favourite tool so far?

#9 What materials are you using to print with?

#10 How was the installation training?

Request a demo!

Feel the strength of the 3D printed parts for yourself.

#11 Have you had any teething problems?

#12 Have there been any other benefits from using additive?

#13 What is the future?

#14 End – final words

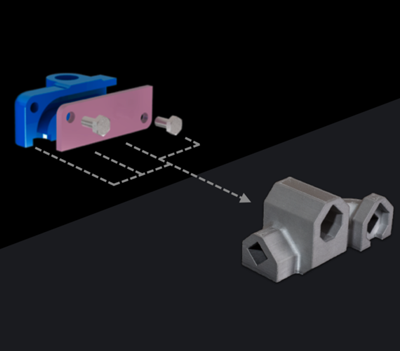

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.