BEULCO GmbH & Co. KG specializes in the manufacture and processing of high quality products for the water supply.

The multi-award-winning family company based in Attendorn has been using additively manufactured parallel grippers and suction grippers for workpiece handling with robots since January 2020 and has already saved £200,000.

Project Goals

Independence through complete in-house production.

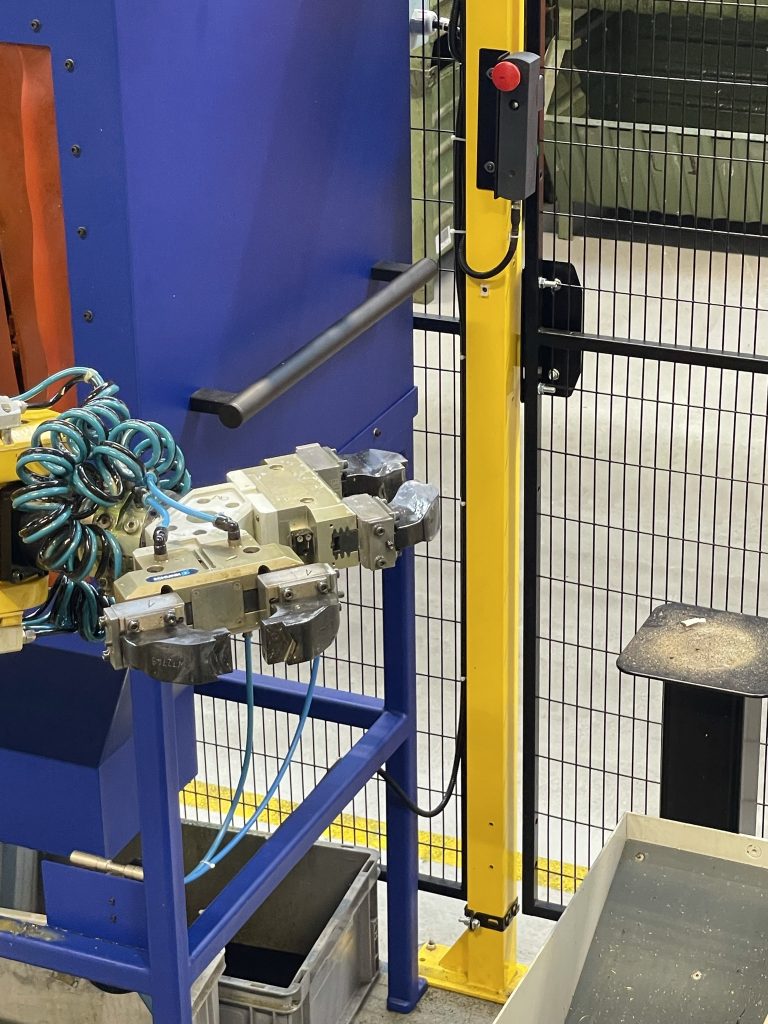

BEULCO GmbH & Co. KG uses parallel grippers and suction grippers for workpiece handling with robots and was faced with several challenges at the same time.

In production, the workpieces go through two steps. In the first step the components are deburred and in the second step are machined. In both process steps, robots are used as the primary operator.

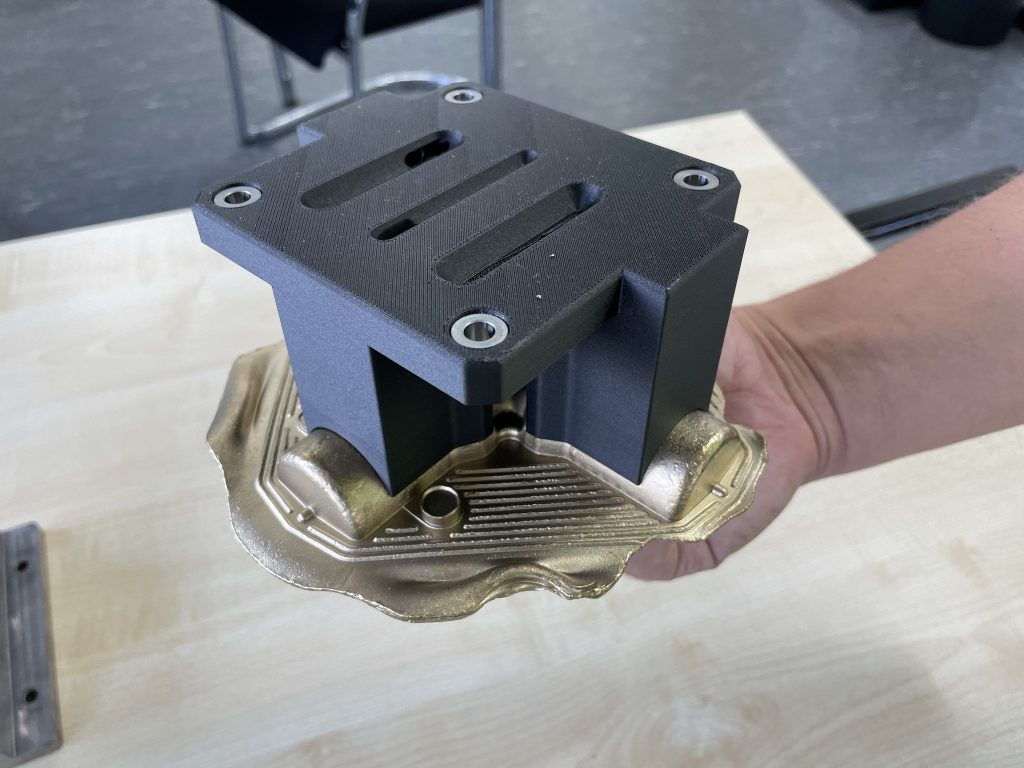

All pressed workpieces have individual contours and there is also a variety of over 300 different designs. In addition, high tool costs meant that a more cost-effective alternative to the existing metal ‘machined’ grippers was sought.

The aim was to cost-effectively manufacture individual, industrial-grade robot grippers.

Overview

The Solution

Fast and Reliable to Customer Satisfaction.

At the EMO 2019 in Hanover, Lutz Schopen, Management Technology, discovered the technology of the industrial Markforged 3D printer. The possibility of reinforcing the components with the continuous carbon fiber during printing was the main criterion for him when choosing a printer. He quickly realized this technology would be a game changer in the field of gripper technology for BEULCO. He believed there would be a drastic reduction in costs to manufacture end-of-arm tooling.

Steep learning curve after initial scepticism in the team.

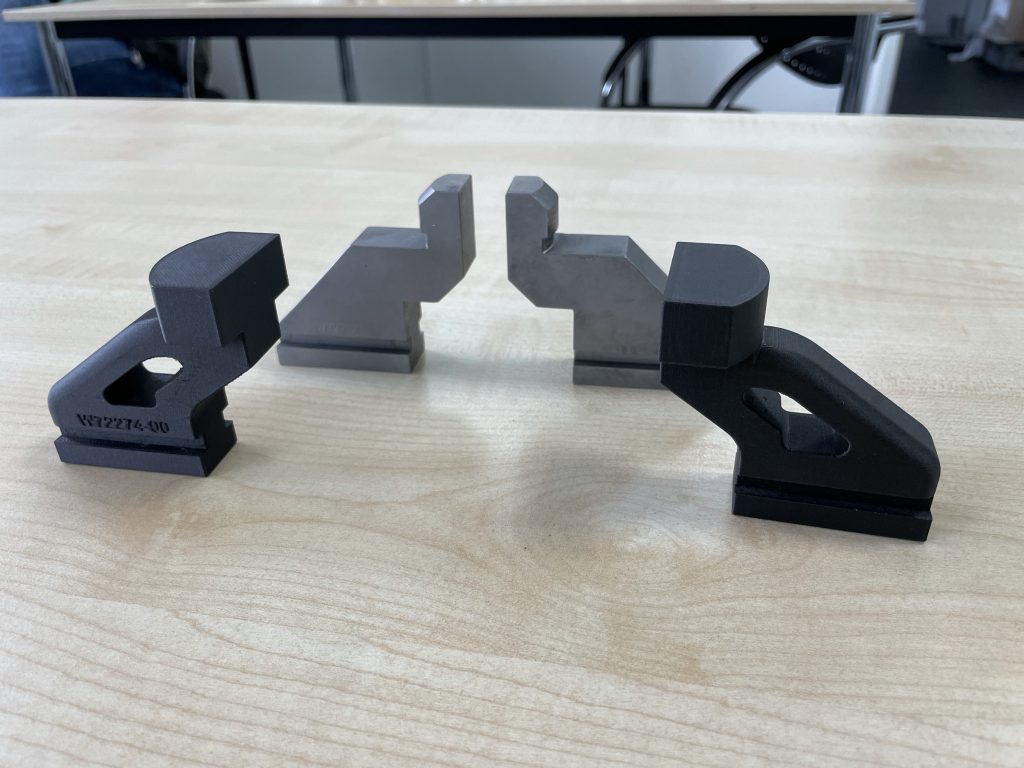

At first, the team was sceptical of the new technology. “If it’s not made of metal, it can’t last.” – was the original quote from the team. An initial sample component from Mark3D was able to convince the team quickly, with results from trials. The first wear tests could be carried out and experience gained on this test stand. Among other things, a separate concept for connecting the gripper to the robot was developed, which a rethink in the design had taken place.

The grippers have now been optimized for additive manufacturing during the design phase.”

Request a demo!

Feel the strength of continuous fiber for yourself.

Implementation

In the course of this, the connection of the grippers was changed from a force fit to a form fit. The groove of the gripper is pushed into a C-groove of the robot, clamped with a plate and screwed. The weak points of the fastening could thus be eliminated. Due to the modular structure, it is now possible that the grippers can be used in both processing steps on the robot systems.

Additively manufactured grippers exceed expectations: No wear and tear on suction grippers noticeable!

“Not a gimmick, but real means of production at BEULCO GmbH & Co. KG!” Emphasizes Lutz Schopen. The new additively manufactured grippers meet the requirements in 99% of the applications. Some of the suction cups have already been in use for over 200,000 cycles and show no measurable wear. The high loads from fast movements have no effect on stability, nor do cooling lubricants with which the components come into contact.

Furthermore, the procurement times (external procurement) could be reduced significantly from 4-6 weeks to 1-2 days, in the ideal case to 24 hours. There are also gigantic savings. A total of £200,000 has already been saved with over 330 printed gripper pairs and suction grippers. The Mark Two 3D printer paid for itself in less than two months!

Suction Cup in Detail Milled Steel Weight: 3194 g Costs: £1,145.00 Delivery time: 4-6 weeks

Additively Manufactured Weight: 189g Costs: £100 Delivery time: 24 hours

The Future

Additively Manufactured Clamping Jaws

Replacement grippers and grippers in new designs are still planned for the future. There is still a regular need here.

BEULCO GmbH & Co. KG sees additively manufactured clamping device jaws as a further field of application for the series production of workpieces on automatic lathes and machining centers. Here, BEULCO is faced with challenges such as strong forces and high heat generation. A solution is being worked on together with Mark3D GmbH.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.