By “drag and drop” to the 3D printed prototype with the

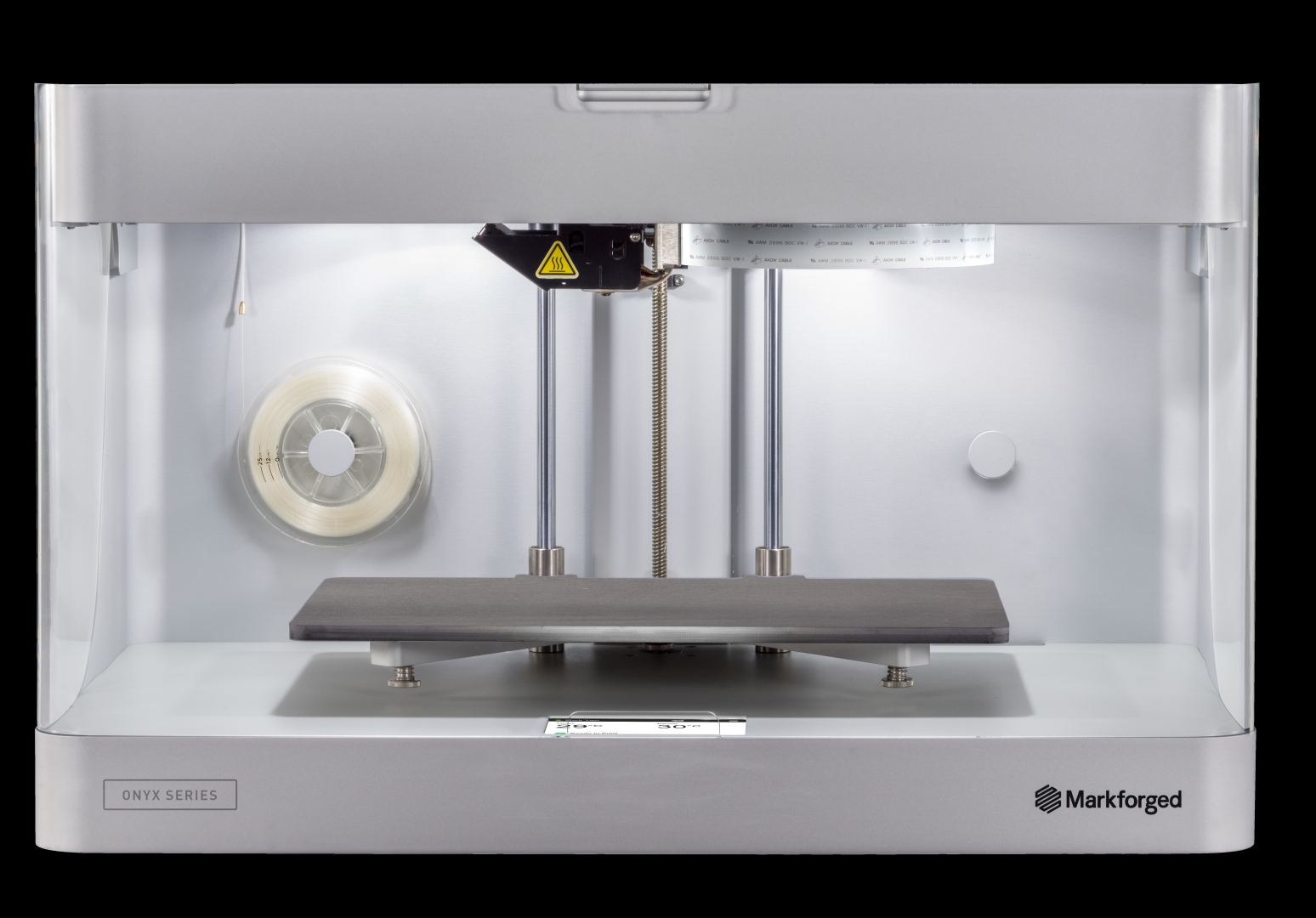

Markforged Onyx Pro

KAJA stands for clear design and quality “Made in Germany” in bathroom and kitchen fittings but also for customer-specific, individual special solutions and reliability. High-quality materials and excellent surfaces turn KAJA fittings into masterly trend objects. All KAJA products are assembled and tested on site.

With the use of the 3D-printer from Markforged and the SOLIDWORKS software solutions, it is possible for KAJA to print prototypes overnight, which are in no way inferior to those made of cast iron, but are visibly faster and more cost-efficient to produce. In addition, conventional production methods during development no longer need to be considered. The combination of SOLIDWORKS and the Markforged 3D printer Onyx Pro is the perfect complete solution for KAJA.

„The Markforged 3D printers in combination with SOLIDWORKS are perfect for us!“

Challenge

The challenges for the Kaja team are to develop attractive, high-quality fittings according to customer requirements, combining design and function. The developments have to be realised in ever shorter cycles, taking into account cost-effectiveness and feasibility.

Solution

“Thanks to the Markforged 3D printer, we can now respond even faster and more individually to customer requirements!”