Serial spare parts production with industrial 3D printing at mayer-technology GmbH & Co. KG.

mayer-technology from Heilbronn is a company of the Mayer Group and bundles know-how in the field of production and machinery within the group.

Additive manufacturing technology achieves a process-optimized increase in productivity and machine utilization as well as a stabilization of the supply chain.

Project Goals

Interrupted supply chain led to machine downtime

In March 2020, one of Europe’s leading groups in the manufacture and distribution of shipping and packaging solutions faced the challenge of a broken supply chain. A gigantic volume of spare parts could no longer be serviced, which in turn led to machine downtime.

As a leading manufacturer that produces products for global mail order companies, among others, the failure of a production machine can lead to very significant challenges. Around 16 billion envelopes are produced annually on 136 web and 59 sheet-fed machines!

Through a partner company, Ralph Schneider, Head of mayer-technology came across the innovative technology of industrial Markforged 3D printers.

His vision was to use this technology to cover at least 10% of the Group’s machine spare parts volume.

Overview

The Solution

Additive manufacturing with composite materials

The result then exceeded expectations after all. mayer-technology is on hand with full expertise to provide advice and support for all of the group’s production sites in Europe. One of the company’s goals is the central procurement, simplification and standardization of all spare parts.

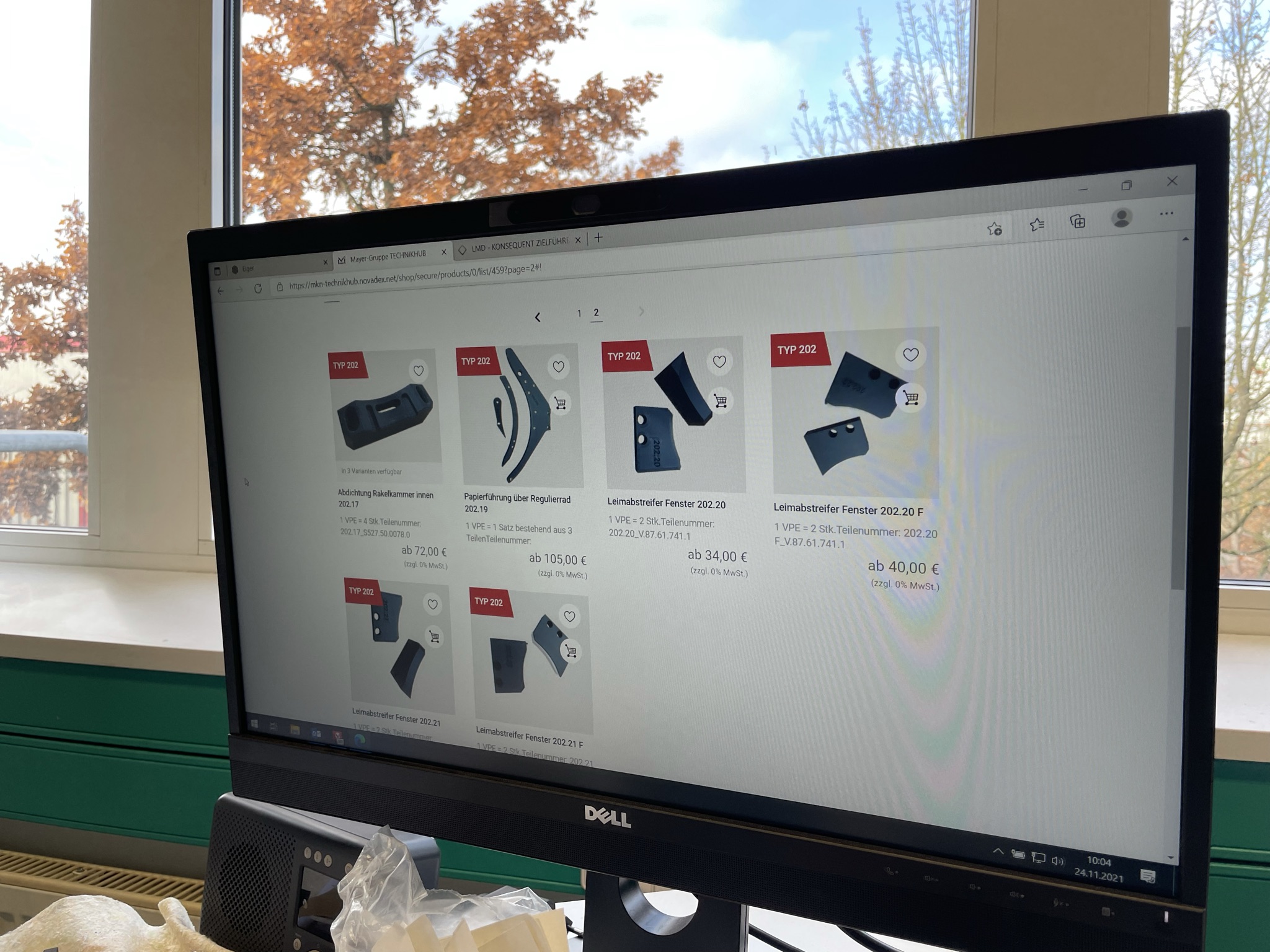

This in turn has resulted in a technology hub, an online store through which all machine spare parts are already available to all Mayer Group sites throughout Europe. The additively manufactured machine spare parts are already sorted by packaging unit and can be ordered at the push of a button.

Availability, independence and innovation

mayer-technology is now facing gigantic savings itself. Numerous components achieve savings of up to 90%. The availability, independence and innovation possibilities of the company are thus now at a completely new level.

Missing design data is created by reverse engineering or manual drawing. The Markforged 3D printers offer an ideal solution, especially for discontinued or hard-to-find machine spare parts. With the precision, reliability and strengths, several hundred components can already be reasonably substituted today.

At mayer-technology, additive manufacturing thus already goes far beyond rapid prototyping and is already a fully-fledged manufacturing technology today!

How can plastic components achieve the necessary strengths?

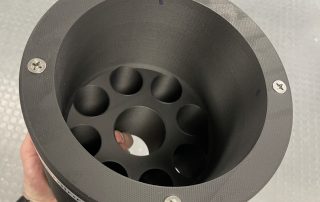

mayer-technology relies on the composite fiber technology from the Markforged 3D printers Mark Two and X7.

The base material is Onyx. A PA6 with 15% carbon short fiber content. Via a second nozzle in the print head, the components can be reinforced using a continuous fiber made of carbon, aramite (Kevlar®) or glass fiber. Depending on the application, the different fibers offer different added value. The continuous fiber has only one starting and one end point per layer. The position of the fiber can be individually selected in the Eiger software.

So thanks to Markforged’s industrial 3D printers, carbon can now be used like a block of aluminum, achieving strengths that exceed aluminum, with excellent surface accuracy.

For larger components and parts made from Ulthem™ 9085 filament, Ralph Schneider will be using the new Markforged FX20 in the future.

Heavy Metal from the Markforged Metal X

With the Markforged Metal X system, components can be manufactured from different metals in a completely new form. The system also relies on the classic layering process. The components are then washed and sintered. In addition to 1.4542 stainless steel (17-4), copper (99.8%) and 1.7744 Inconel (625), various tool steels are also available. Even larger components, even shorter delivery times. The print farm of mayer-technology GmbH & Co. KG is growing steadily and currently already includes almost 20 3D printers.

“The opportunities available to us with Markforged technology, have revolutionized the spare parts business.” – Ralph Schneider, Head of mayer-technology GmbH & Co. KG

Request a demo!

Feel the strength of continuous fiber for yourself.

The Digital Forge

When you walk through the production at mayer-technology, you quickly notice that each individually printed component carries a serial number or component identifier. “If a component or part of an assembly is damaged or worn, a replacement part can be reprinted on-demand. This avoids long delivery times and warehousing costs, explains Ralph Schneider. It also eliminates warehousing costs. The warehouse is now located on the roll of filament. In addition, the whole system can be operated super simply in a plug & play process, he adds.

The Future

Partner for external spare parts management

Time is money. Solve your spare parts procurement via industrial 3D printing. From now on, mayer-technology is making its additive machinery and know-how available not only internally but also to external companies. This means that long delivery times and supply chain dependencies are a thing of the past. A solution can be found for almost every initial situation – with savings of up to 90%.

The volume of additively manufactured spare parts at mayer-technology will continue to increase in the future.

Roller before / after comparison

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.