SNG Barratt Ltd

When it comes to mission-critical components, strength isn’t optional, it’s essential. This metal 3d printing strength test shows how SNG Barratt Limited, used Markforged Metal X technology to remanufacture an OEM-spec bottle jack for the Jaguar E-Type. The results didn’t just match the original casting, they exceeded it under real compression loads.

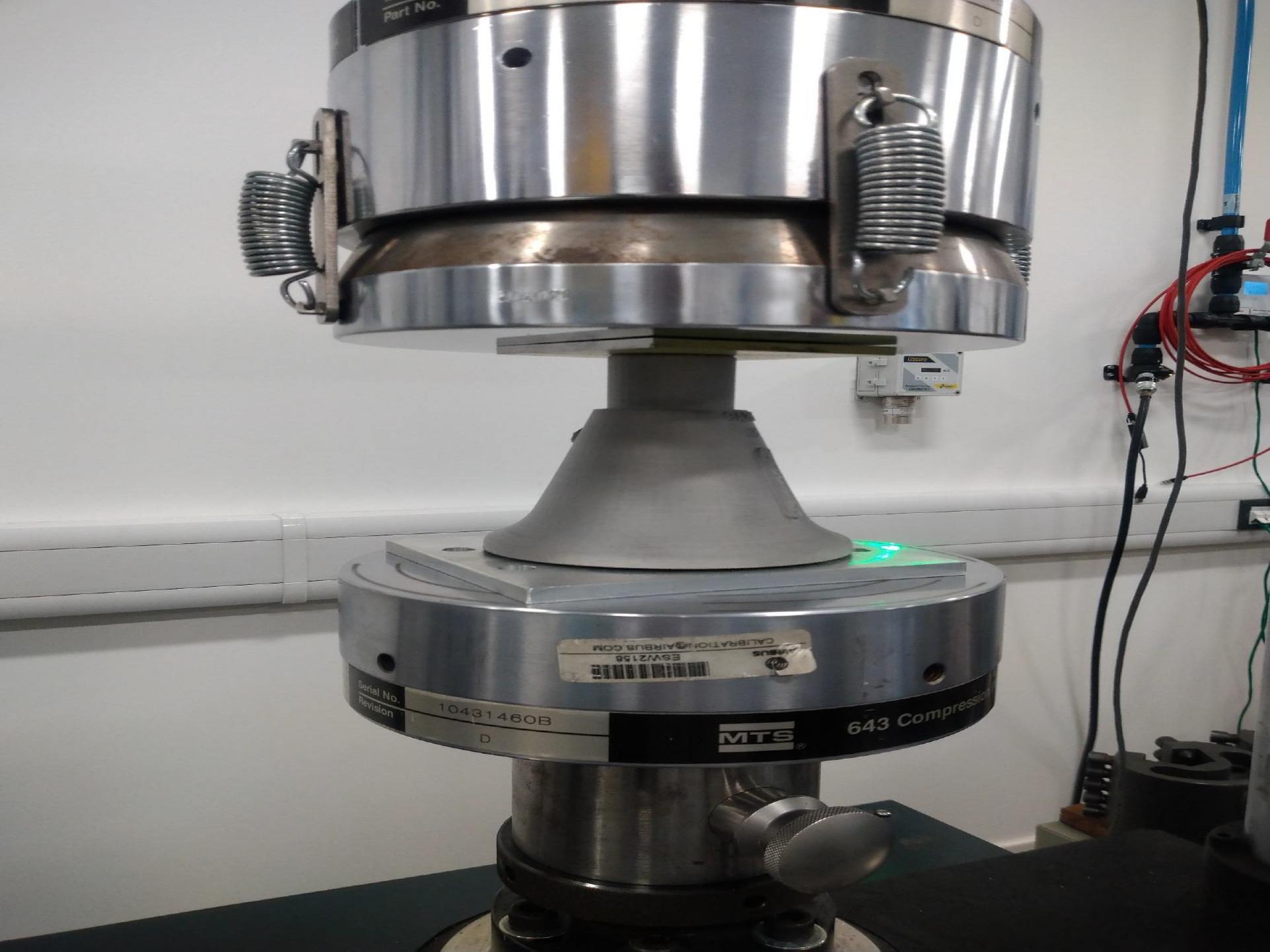

The big question was: is it strong enough to safely lift a six-figure classic car? To find out, SNG Barratt printed the part, finished it to OEM spec, and sent it for independent compression testing alongside the original cast version.

The result was decisive: the cast jack failed at 66.5 kN, while the metal 3D printing strength test version withstood a full 95 kN (over 9.5 tonnes) without failure, outperforming the original cast part. Strength proven – and production transformed.

Download the full case study to see the results in detail.

It’s the question everyone asks – is it strong enough? The test results gave us absolute confidence. The printed part outperformed the original casting.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? - This is the right place for you! The guides below can tell you everything you need to know.