Carbon-Fibre

What is Carbon-Fibre?

The stiffest and strongest fibre with the highest strength to weight ratio.

When should I 3D print with Carbon-Fibre?

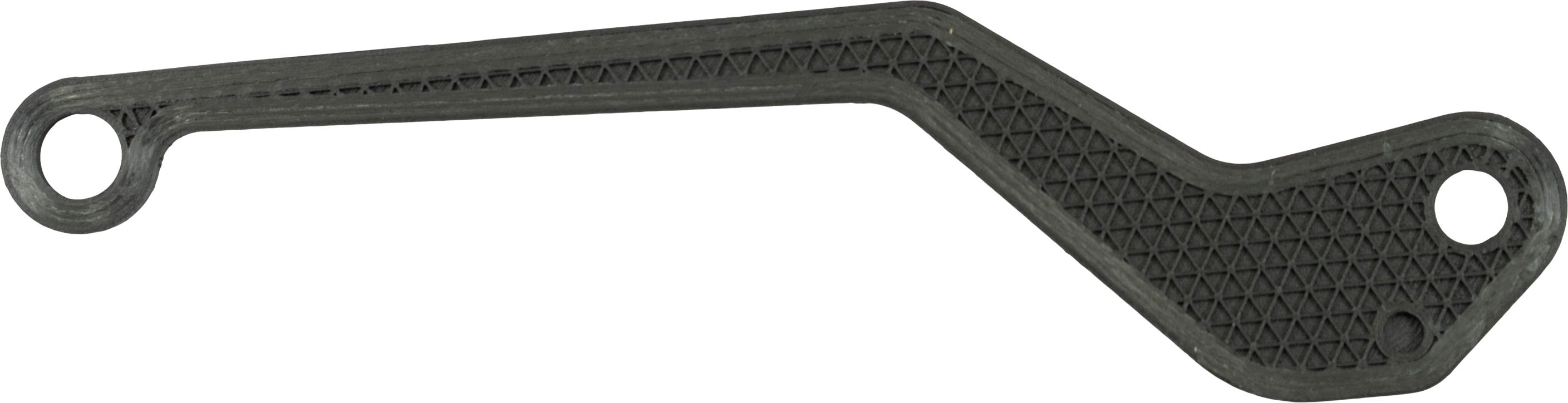

Carbon fiber material is strong enough to replace aluminum 6061 at half the weight; use it when you want superior stiffness and minimal deflection.

Robotic arms

Forming tools

Inspection fixtures

End Use Parts

First CE-certified 3D printed part

Wärtsilä is a leading global supplier of intelligent technologies and system solutions for the shipping and energy markets, with a product portfolio ranging from motors to drive and renewable energies. The tool made of onyx with carbon continuous fiber has undergone various tests and inspections, resulting in the first 3D-printed, CE-certified hoisting tool.

“The best thing about 3D printing is that any design can be printed anywhere and at any time, even on the cargo ships that Wärtsilä helps maintain and service.”

Juho Raukola, additive manufacturing manager

Request a demo!

Feel the strength of continuous fiber for yourself.

FAQ

What is Carbon-Fibre?

Carbon fiber is a thin filament made up of carbon atoms organized into a crystalline structure. Because of its very high stiffness and strength it is widely used in the aerospace and automotive industries.

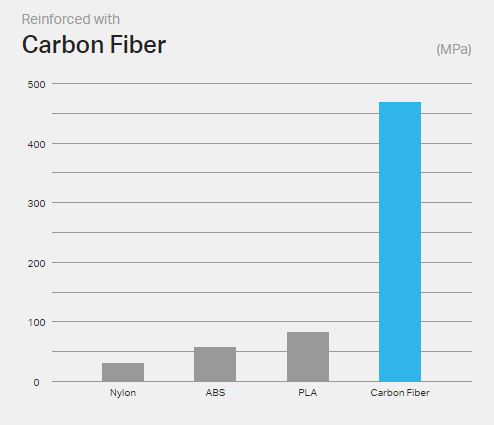

How strong is Carbon-Fibre?

Carbon fiber has a flexural strength of 540 MPa (78.3 ksi) which is more than 6 times greater than parts printed in only Onyx. It’s tensile strength is 800 MPa (116.0 ksi) more than twice the ultimate tensile strength of aluminum 6061. To learn more about carbon fiber material properties, check out the data sheet.

What does the carbon fibre filament cost?

A 50cc spool costs £120.00 excl. VAT and a 150cc spool is £360.00 excl. VAT.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.