HSHT Fiberglass

What is HSHT Fiberglass?

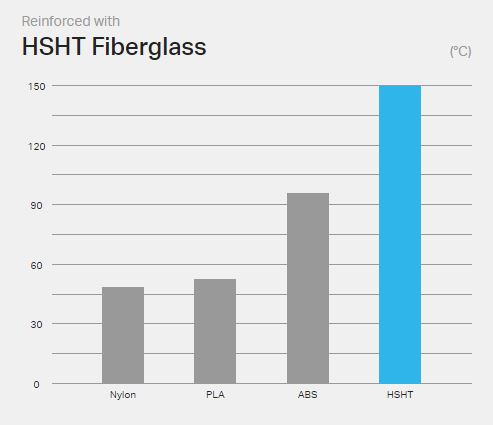

HSHT Fiberglass material (High Strength High Temperature) delivers the highest impact resistance and heat deflection temperature of our continuous fibers.

When should I 3D print HSHT Fiberglass?

With superior heat resistance and a flexural strength that is second only to carbon fiber, HSHT fiberglass is ideal for applications requiring high heat and impact resistance or high elasticity.

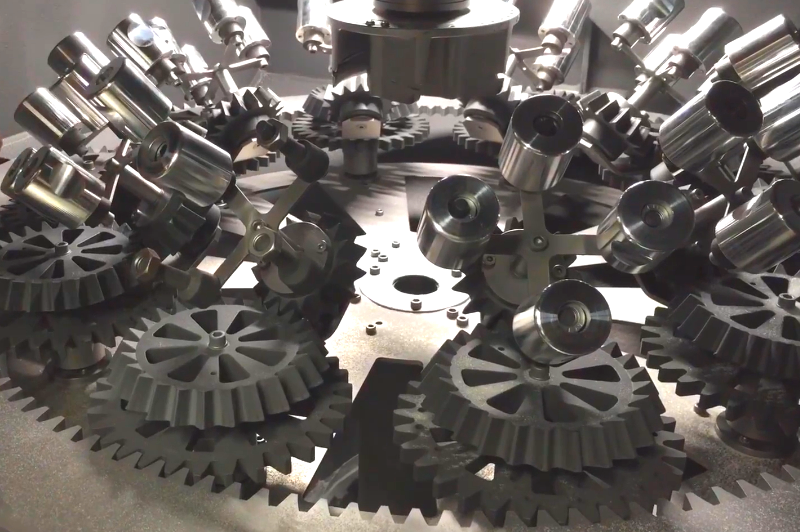

Welding fixtures

Thermoset molds

Thermoforms

Mold inserts

3D printing industrial equipment from prototypes to high volume parts

Intensive tests, including specific long-term testing, showed that the Markforged base material ‘Onyx’ is also suitable for components with high mechanical loads, such as the machines beam area.

“We only manufacture what is needed immediately. Our warehouse is now on a spool!”

Chris Tettalowsky, Head of Blasting Systems

Request a demo!

Feel the strength of continuous fiber for yourself.

FAQ

What is High Strength High Temperature (HSHT) Fiberglass?

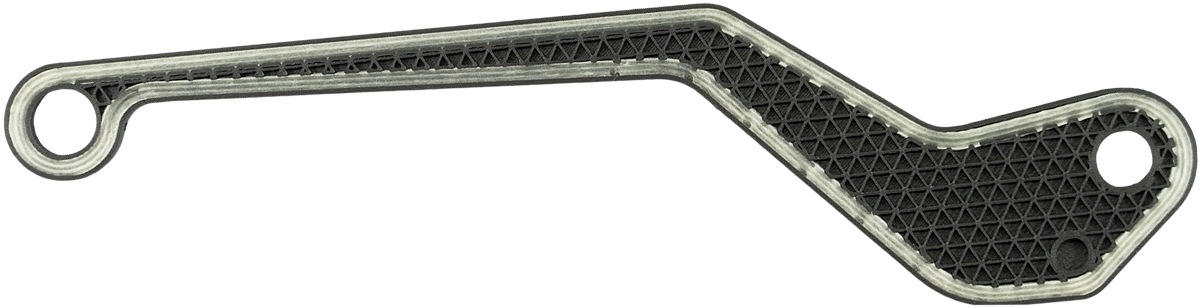

Extremely thin strands of glass bundled together into a fiber. Fiberglass is traditionally used in composites for boat, automobile, and aircraft manufacture.

How strong is HSHT Fiberglass?

HSHT fiberglass has a flexural strength of 420 MPa (71 ksi) and a tensile strength of 600 MPa (87 ksi). For more information on HSHT fiberglass material properties, check out the data sheet.

What does the HSHT Fiberglass filament cost?

A 50cc spool costs £80.00 excl. VAT and a 150cc spool is £240.00 excl. VAT.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.