BD Engineering

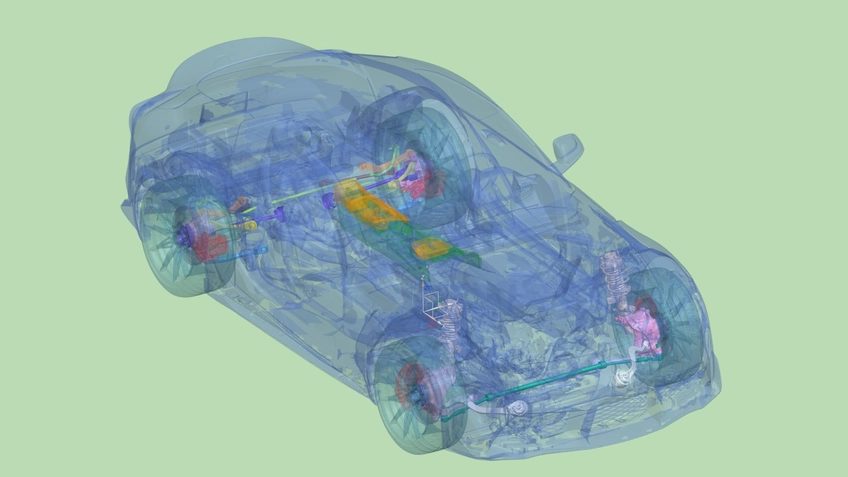

When BD Engineering set out to modify a Toyota Supra for high-performance drifting, they needed a way to capture every component of the car with absolute accuracy and without relying on OEM CAD data. Using Artec Leo automotive 3D scanning and Artec Studio software, the team fully digitised the Supra in record time, creating a precise 3D model that became the foundation for new drift-ready components, including a redesigned hydraulic handbrake and suspension geometry.

By ‘closing the loop’ and scanning the entire vehicle, BD Engineering eliminated error propagation and ensured complete data integrity across the model. The resulting dataset now powers a dynamic simulation environment for testing and development. What began as a demanding reverse engineering project has evolved into a scalable ‘scan-to-factory’ workflow, demonstrating how Artec Leo is transforming productivity, accuracy, and speed in the automotive sector.

Download the full case study to see the results in detail.

In automotive, many people only scan part of a car – but that leads to errors where the start and end points don’t align. We decided to take a different approach and scan the entire vehicle. It’s faster, more accurate and ensures complete data integrity. We call it ‘closing the loop.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? - This is the right place for you! The guides below can tell you everything you need to know.