Markforged 3D Printers – How you can benefit from 3D printing!

3D printing with Markforged is a lot more than printing prototypes and small plastic parts.

Why you should buy a Markforged 3D printer?

The industrial 3D printers can print high-strength parts from the full range of materials from carbon fiber to metal. The unique technology, which enables the printing of carbon fiber and other filaments in combination with onyx or nylon, makes it possible to produce extremely strong components. This opens up completely new possibilities for every professional designer, engineer and constructor. Here we would like to show you why 3D printing can be a very useful process in manufacturing for you too.

Request an individual offer!

Topics:

- Why 3D printing is also interesting for your production

- 3D printing fully integrated into your business processes

- How does 3D printing work?

- From the three-dimensional template to the finished component

- “The barriers between idea and reality are torn down”

- The Markforged 3D Printers

- The Metal X from Markforged

- The Industrial Series from Markforged

- The Desktop Series from Markforged

- 3D printers for schools and universities

- Buy 3D Printers

Global leading companies use Markforged 3D printers

Why 3D printing is also interesting for your production

3D printing is a milestone for the industry. A lot of time and money can now be saved by producing prototypes, small series and spare parts. Some companies have already switched to 3D printing for the production of various small parts. With the printers you can print parts of different sizes in various base materials such as onyx, nylon or metal. For fibre reinforcement, composite materials such as carbon fibre, fiberglass, high-temperature fiberglass or Kevlar are inserted into the component to make it even more stable. The base materials are applied layer by layer, while the composite materials are added in a continuous fiber from a second print head. This way unique and high-strength components can be produced with enormous savings in cost, time, weight and material! Compared to classic CNC milling, 3D printing generates significantly less waste and harmful substances. Furthermore, any conceivable geometry can be produced, such as internal cavities.

Case study: jigs for a TRUMPF laser welding machine Primetall needs individual fixtures for some components in order to clamp them on a laser welding machine. These jigs were previously made of aluminium and were very heavy and expensive to produce. The jig was optimized with additive manufacturing and reinforced inside with a continuous carbon fiber. In addition, a zero-point clamping system was added and channels were integrated inside the jig. Now forming gas can be directed to wherever it is needed – with only one gas connection! It was practically “drilled around the corner”. That is manufacturing redefined. The production of this device with a 3D printer has a saving of 1060€ per device compared to conventional production!

3D printing fully integrated into your business processes

Less waste

Less material

No harmful substances

Reduced costs

Fast production (overnight printing)

Production of all shapes

How does 3D printing work?

With 3D printing, any conceivable geometry can be produced. The forms must be available in digital form in three dimensions. The CAD files are processed at the Markforged printers in the cloud based EIGER software. As soon as the file is loaded into the software in STL format, printing can begin. If necessary, the printer automatically creates a support structure which can be easily removed after printing. With additive manufacturing (also called generative manufacturing), the component grows from bottom to top. Furthermore, there is an adjustable grid structure inside the component. With this the stability of the component can be varied as desired. With topology optimization, additional material can be saved – with the same stability! Markforged’s professional 3D printers meet the industry standard and convince with their highest precision, quality and surface finish.

The EIGER software from Markforged

From the three-dimensional template to the finished component

3D printing of composite materials requires innovative software. With EIGER, the intelligent, cloud-based platform, you can easily monitor the stability and quality of your components. Whether you have a 3D printer or an entire “printer farm”, you can work and organize everything in one integrated system. Typically, one person can operate an entire “printer farm” of multiple printers. So you can produce and optimize your prototypes or spare parts according to your own ideas.

Request a demo!

Feel the strength of parts for yourself.

“The barriers between idea and reality are torn down”

With Markforged 3D printers every design concept, every geometry becomes reality! With an working space of 330 x 270 x 200 mm and a layer height of 50μm in the X-Series, ideal components for robotics, automotive industry or prototype construction can be produced. Markforged has achieved a breakthrough in the quality and precision of 3D printed components thanks to laser-assisted construction process control*. The printing layers are scanned by a laser while the printing is still in progress to ensure highly accurate, industry standard printing results.

*The laser-assisted construction process control in the X-Series is only integrated in the X7.

The Markforged 3D Printers

Unique 3D printing experiences

Desktop Series.

Desktop Series.

Print components directly on your desk!

Industrial Series.

Industrial Series.

Complete flexibility with highest quality and precision!

Metal X.

Metal X.

Print industry-standard metal components!

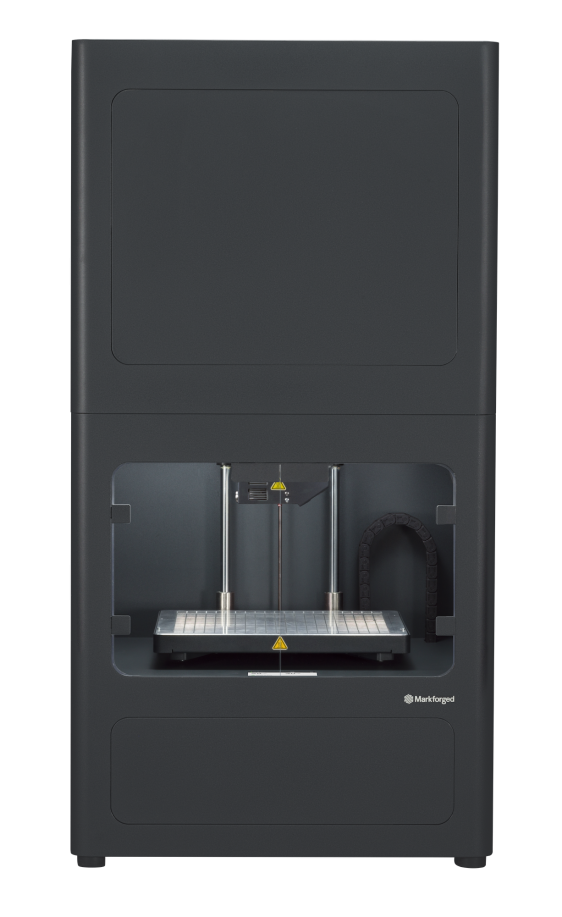

The Metal X from Markforged

Metal components out of the 3D printer

The Metal X is an industrial revolution and delivers metal components to you overnight. Forget 20th century manufacturing and create everything from industrial spare parts to injection molds to functional prototypes with the Metal X.

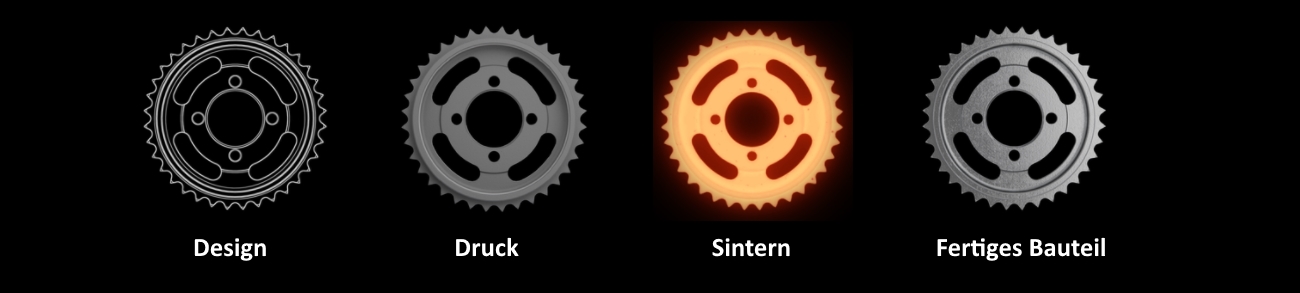

Thanks to the ADAM (Atomic Diffusion Additive Manufacturing) process, there is now a completely new way of manufacturing metal parts. In this process the components are printed, washed and sintered. The result is a component that is ready for use.

The Industrial Series from Markforged

Uncompromising Strength, Precision and Beauty

The Markforged Industrial Series takes fiber-reinforced 3D printing to a whole new level with laser-assisted build control (X7 only) and a large build envelope. Components are printed exactly as they are designed, with unparalleled quality, dimensional accuracy and stability.

The Desktop Series from Markforged

Industry-leading stability on every desk

The Mark Two combines the unique technology of continuous fiber reinforcement with incredible reliability, printing stable and versatile components. It is the only 3D printer on the market that can produce perfect functional parts from CAD data within hours. You can specify the strength and material and either insert the part directly or process it further as soon as it comes out of the 3D printer.

3D printers for schools and universities

We at Mark3D also work closely with the educational sector. 3D printers encourage spatial thinking, creativity and imagination in a unique way. As a partner of a large number of universities and other educational institutions, we can offer you specific advice and support. Please contact us!

By getting started with professional 3D printers, students gain a real advantage in the highly competitive and competitive job market.

Learn more about 3D printing with continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.