CAD-Software

[7 minutes reading time]

The choice of the appropriate CAD software

There is a large number of CAD software programs on the market. But which software is the right one for you? Medium-sized and industrial companies attach great importance to efficient, fast and intuitive work.

SOLIDWORKS 3D-CAD – The perfect CAD software for additive manufactured components

The 3D CAD software SOLIDWORKS from Dassault Systèmes has proven itself for the design of additive manufactured components. After only a minimal training period in SOLIDWORKS, you will benefit from the advantages of this powerful, fully parameterized 3D design solution for the rapid creation of parts, assemblies and 2D drawings.

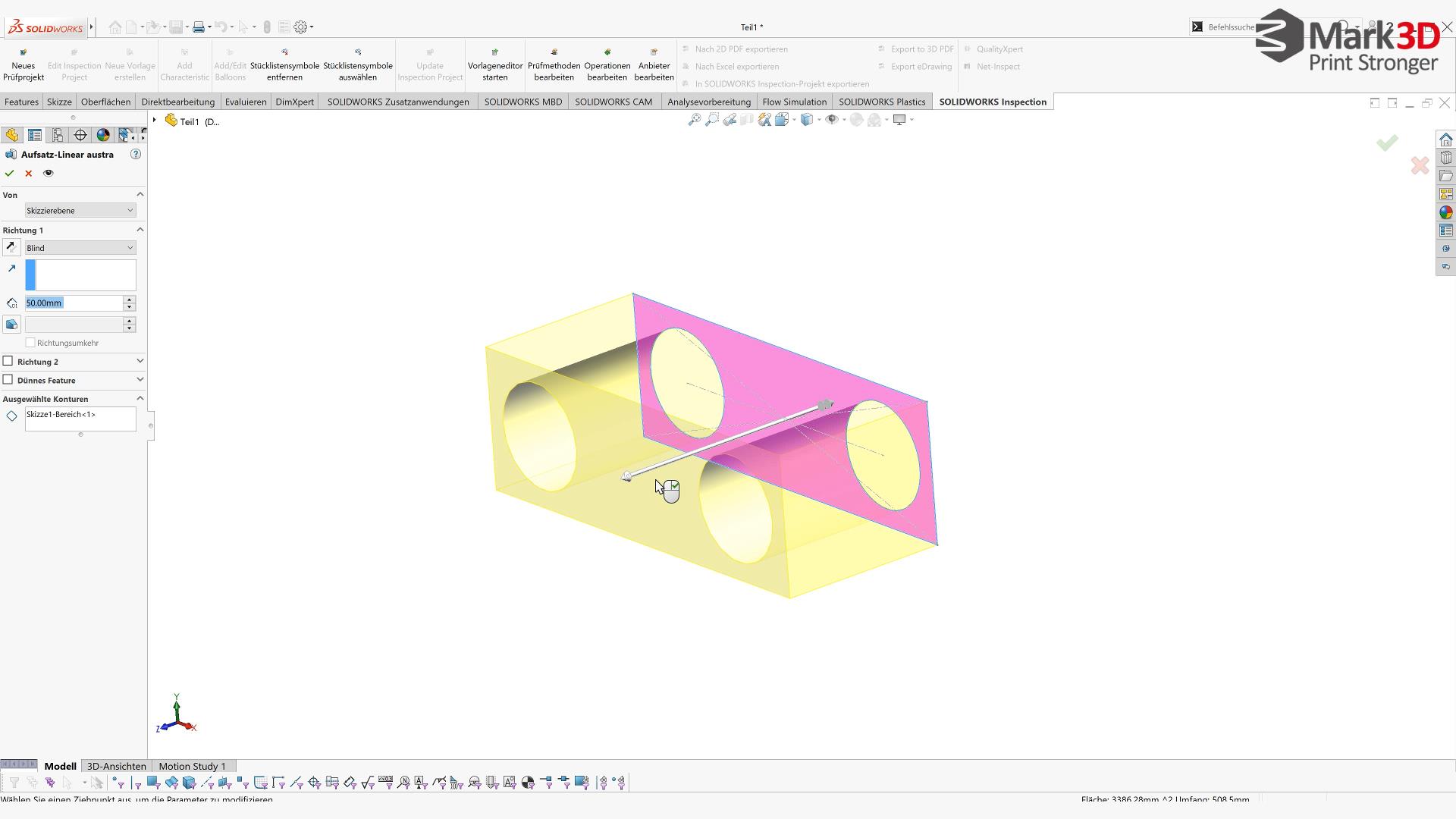

SOLIDWORS is intuitively structured and the user-friendly interface can be individually adapted to your needs. The creation of solids is based on 2D sketches. These sketches can be created in no time. You always have the necessary commands for creating sketch entities directly at the mouse thanks to the interactive menu. For example, you can create lines, circles, or rectangles and parameterize them with dimensions or conditions such as “equal” for the same length or diameter. Extracting, building volumes or subtracting, subtracting a volume, your 2D contour is easy to perform thanks to a preview and a length scale.

Further sketches can be built on the basis of existing bodies in dependence. Link new sketch entities to existing edges. This quickly creates an associative 3D model that can be easily modified for revision. Because if you change a dimension in the sketch, all dependent components adapt as well.

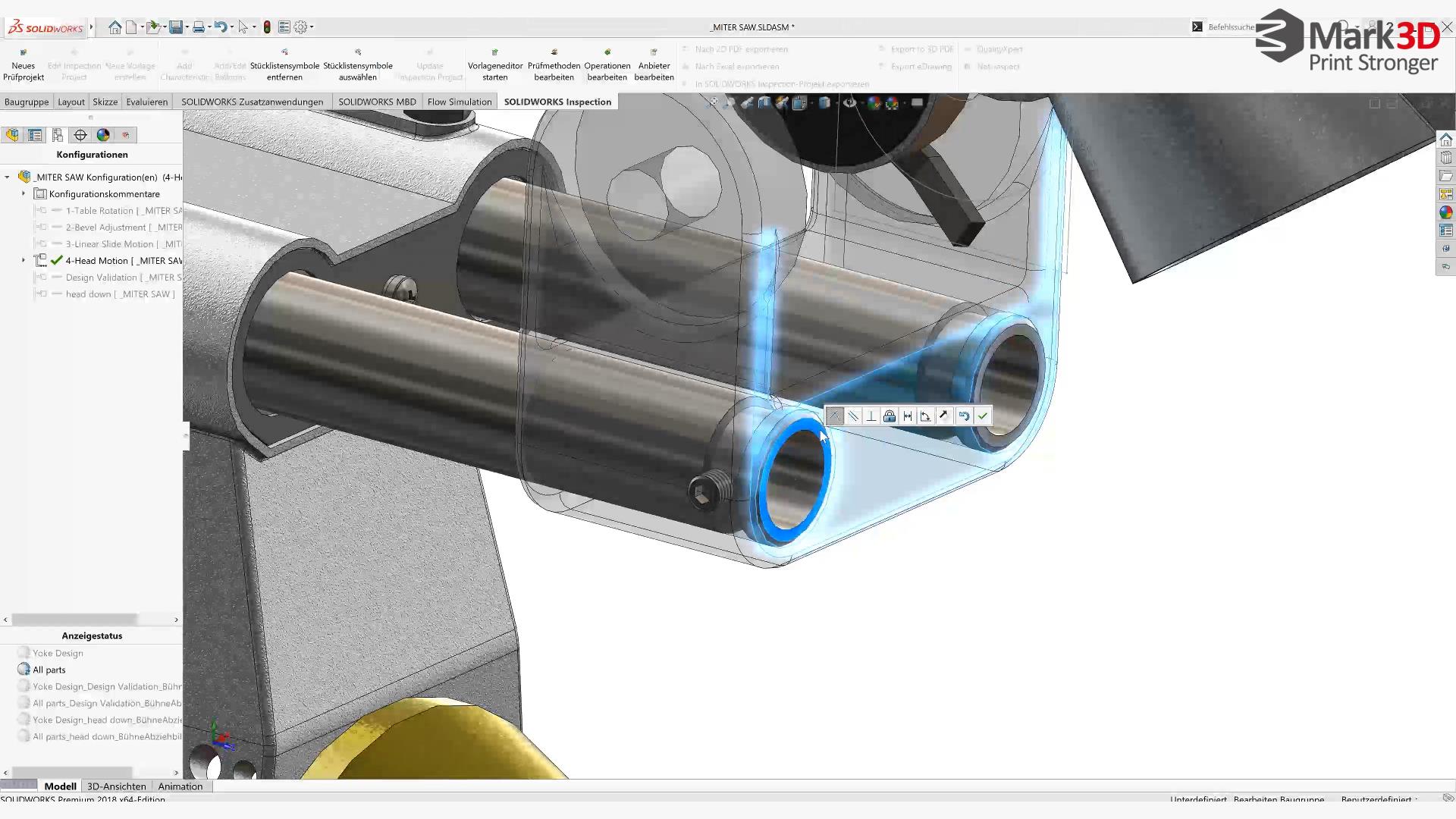

Numerous features support you in the creation of solids, tool and mould components and much more. Even inserting a component into an assembly is very easy. You position your component at the approximate installation position and the SOLIDWORKS assembly links, such as “Concentric” or “Distance to”, support you in alignment. Mechanisms and motion sequences can be checked and controlled immediately.

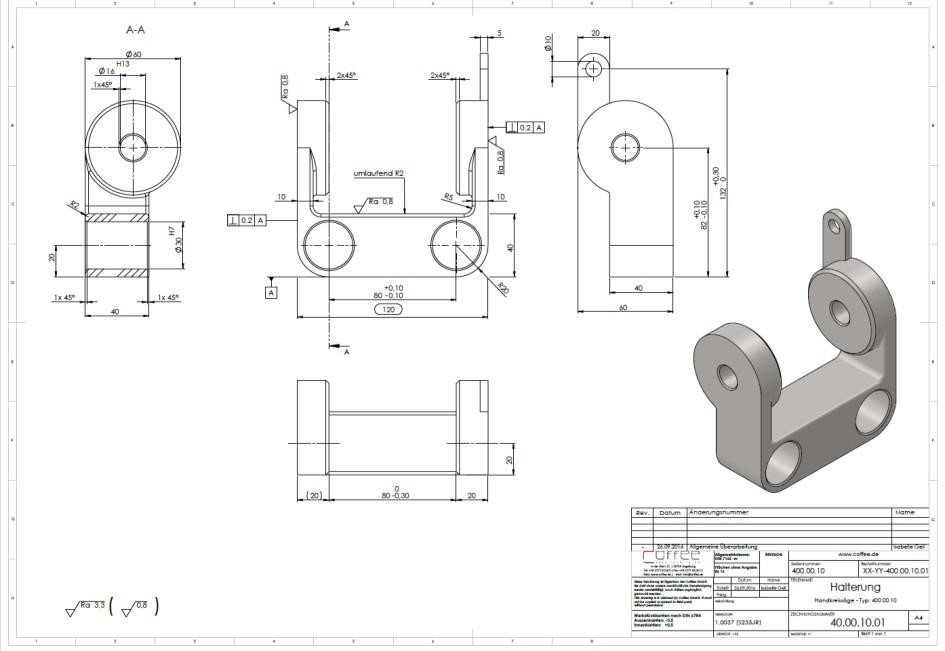

Of course, SOLIDWORKS also offers you the possibility to derive production-ready 2D drawings from the 3D model. The drawing is created directly in relation to your 3D model. Front, side and top views are displayed according to the desired drawing standard. Even sections, detailed views and perspective views are quickly derived. Dimensions and tolerance specifications defined in the model can be imported into the drawing with a click of the mouse, so that no dimension is forgotten. SOLIDWORKS 3D-CAD helps you to build up your contrasts efficiently and intuitively, use these possibilities for fast results.

SOLIDWORKS offers the best package from one source for every industry. You can also choose from a wide range of industry-specific special tools. Let your SOLIDWORKS specialist COFFEE advise you.

Markforged uses SolidWorks Software

The Markforged 3D printers were developed with SOLIDWORKS 3D CAD. Furthermore Marforged uses the products SOLIDWORKS PDM & SIMULATION.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.