Costs for 3D printers

[5 minutes reading time]

What are the costs involved in purchasing a 3D printer?

As with any new device, it is difficult to say how quickly the investment will pay off. Printers are available from 200€ (hobby printer) to 1 million Euro. However, there is a wide range of printers in the medium price segment (3,500€ to 100,000€), which are suitable for small and medium-sized companies with production requirements. Here we have put together some information about the different types of printers:

Hobby section

3D printers for hobbyists are usually between 200 and 3000 euros. They are a great option for those who want to print toys and occasional prototypes or spare parts. Users have access to a limited print bed size and a limited choice of materials.

Professional sector

These printers are used by companies that need larger, high quality parts that hobby printers cannot produce. Printers in the professional category cost between 3,000 and 15,000 euros.

Industrial sector

Industrial printers are often able to produce high quality parts in a relatively short time. However, these printers are more expensive than hobby or professional printers. Typically, industrial printers cost between 15,000 and 150,000 euros.

Large format printers

These printers are much larger than all other printers and require a lot of space and knowledge to operate. They usually cost between 150,000 and 1 million euros or more.

Costs per part

With so many different types of parts manufacturing, we think it’s best to compare the three most commonly used processes: in-house machining, third-party shipping, and in-house 3D printing.

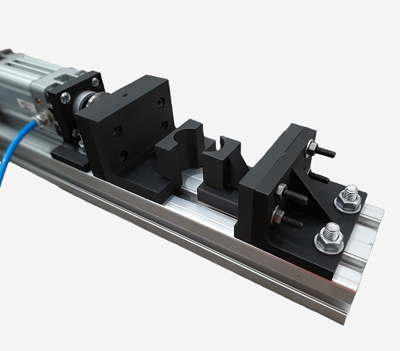

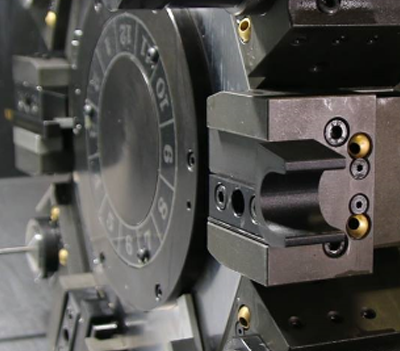

In-house machining

If your machinist’s time is 70 euros per hour and he needs five hours to design, set up, program toolpaths and actually machine the part, your company will have to spend 350 euros just to do the work required for one part. In addition, you must pay for the materials and equipment used and any modifications.

Shipping to a third party

If you send a design to a third-party vendor, you must wait until after the part is completed for further iterations. This can often take weeks because the part must be manufactured and shipped. Each iteration not only takes time, but also adds costs.

In-house 3D printing

In-house 3D printing of a part is a cost-effective alternative, as you only have to pay one-time machine costs and ongoing material costs. You also don’t have to pay for labour costs, as machine operators don’t have to operate the machine or stand next to it.

Determination of the ROI

To determine your ROI, take the cost of your current manufacturing method and subtract the cost of the printer you are interested in to obtain the savings. Take the price of the printer, divide it by the savings to determine the number of printed parts required to pay for the printer. In this guide, “The economics of 3D printing” we explain how to calculate the ROI.

Business impact

It is important to know that costs are not everything. Printers can bring many business benefits to your company, including design flexibility, faster time to market, greater flexibility and less machine downtime.

Learn more about the applications with the Desktop Series!

How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.