EIGER Software offline

Keeping your 3D printing software up to date when working offline

The ability to access the latest software features is one of the main reasons customers choose cloud-based applications. Because software providers are able to push updates to the cloud as soon as the new code is available, cloud users can immediately benefit from new and improved features.

When connecting to the cloud is not possible, users often have to work with locally installed software that may not have been updated in years. If the on-premise software is frozen in time, the benefits of new features are no longer available to the software’s users.

So what does a user have to do?

Software updates close this gap between cloud and on-premise software. By regularly installing new software versions, offline users can easily keep up with the cloud.

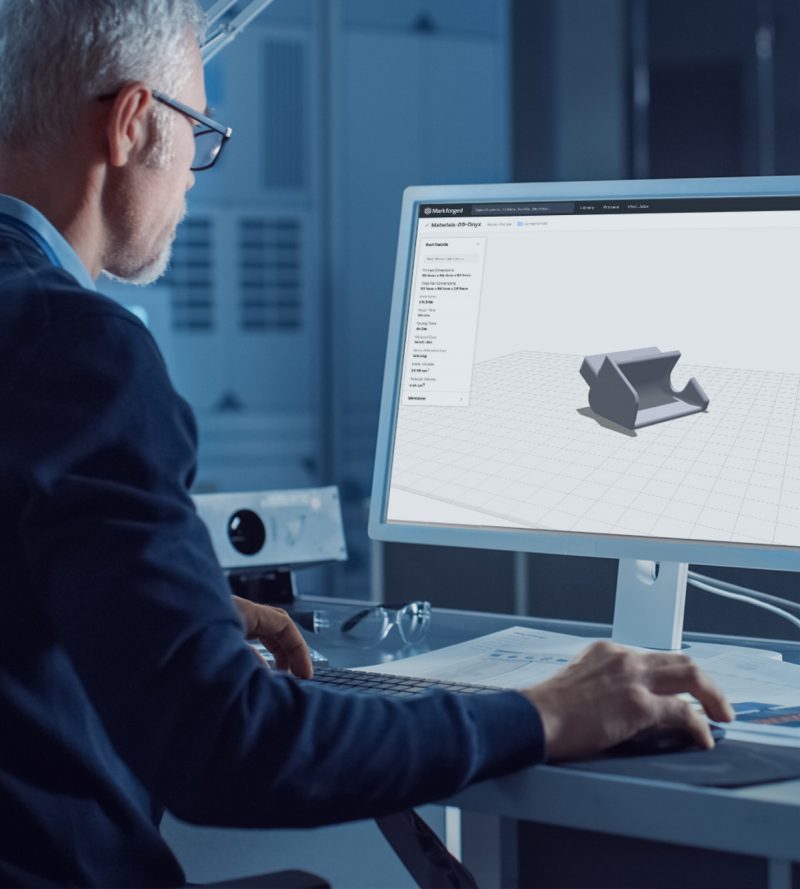

At Markforged, most of our customers use Eiger for 3D slicing and printing in the cloud. For companies that need to keep their or their customers’ parts information on local systems, we offer Offline Eiger, which works 100% offline. For the past year, Offline Eiger has been available as a subscription to help our customers bridge the gap between cloud and on-premise software through quarterly updates that provide the latest features and material support.

Below are examples of new features for offline Eiger users that take advantage of the seven software updates to date:

Request a demo!

Feel the strength of continuous fiber for yourself.