Metal 3D printing with Markforged

3D printed metal components overnight!

Through my contact with over 4,000 mechanical engineering companies and their managing directors over the past 15 years, one thing has become clear to me: Companies that embrace new technologies and continually work on process optimization remain successful.

Major brand manufacturers such as Porsche and Siemens are investing in Markforged, gaining a significant competitive advantage in the era of Industry 4.0. These and other manufacturers relying on additive manufacturing, robots, IoT, and automation are able to meet customer demands for increasingly customized products.

“The customer can have it painted in any color he wants,

as long as it is black” / Henry Ford

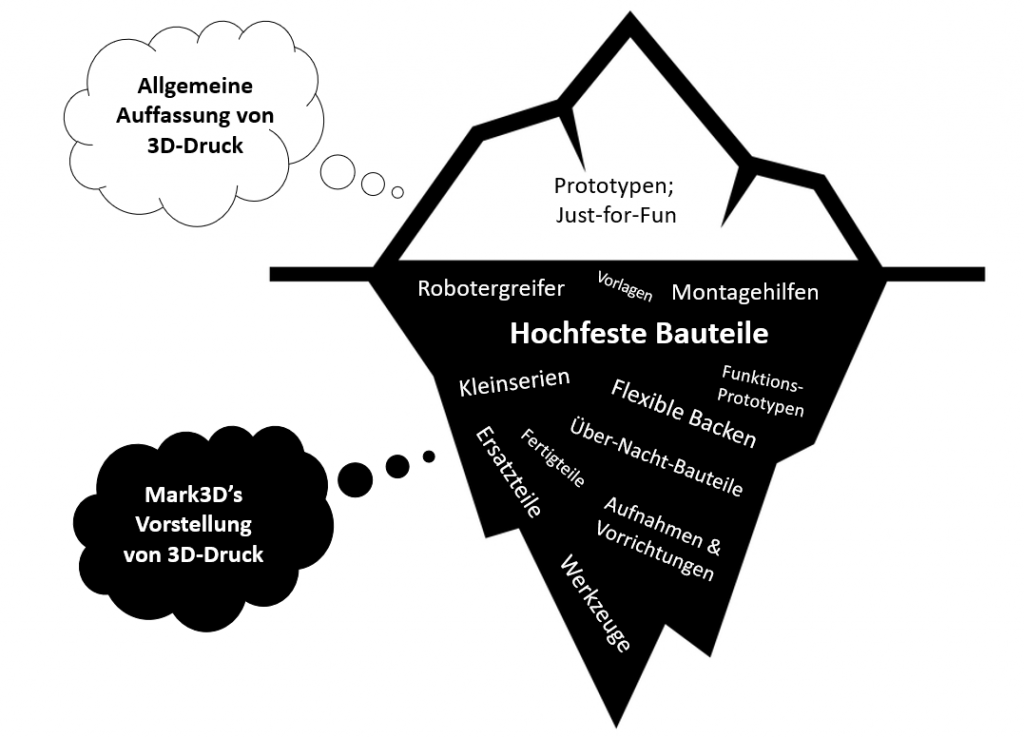

This was necessary back in 1910 to scale production for Henry Ford's customers. Over 100 years later, this couldn't be further from the truth; today's business customers demand products that meet their business needs, while consumers increasingly want something customized and tailored just for them. The market, crowded with makers, DIYers, and individualists, is forcing everyone to act to bring back craftsmanship on a massive, industrial scale. The world wants something impossible: mass customization—all the charm of artisanal, customized production with all the benefits of mass production. In 2018, the reinvention of manufacturing is "mass customization." While 3D printing focused on low-volume cosmetic prototypes, Additive Manufacturing technology now embraces printer parallelization and mass production. Leading companies are embracing industrial-scale Additive Manufacturing for mass production.

It may still sound like something out of Star Trek, but push-button additive manufacturing technology isn't the future. It's happening right now at manufacturing companies around the world. We now have the ability to print strong parts on the same day and produce them more cost-effectively than traditional metal fabrication. Locally and safely, and lighter than cast iron. With the revolutionary new technology of metal 3D printing, manufacturing companies are experiencing new possibilities for producing products at lightning speed. Additive manufacturing is therefore changing the way we design and manufacture products.

“Companies can now reduce production costs for

reduce the production of metal parts by up to 98%.”

With new technologies and lower barriers to entry for industrial 3D printing, the industry is expected to grow by 20% and become a $20 billion industry by 2020, according to Wohlers' 2017 report. Last year, the traditional manufacturing industry was a $10 billion industry.

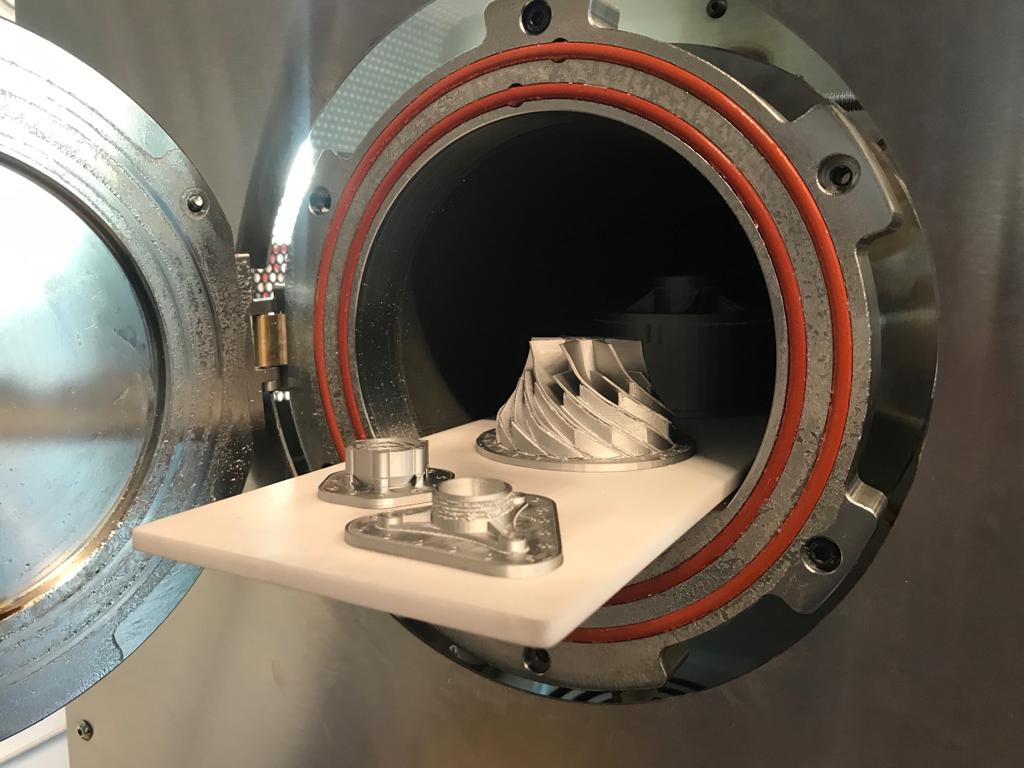

There are several other clear advantages of metal 3D printing, such as faster time to market, weight savings, and the ability to customize products or create parts that are impossible to manufacture using conventional methods. In the past, due to the high cost of metal 3D printers, this was only utilized by companies in the aerospace or automotive industries. Yesterday's 3D printers are the mainframes of manufacturing. They are large, slow, and expensive (€500,000 - €1 million). Here, metal powder is placed on a powder bed and then fused together using a high-power laser or electron beam. This metal powder used in metal 3D printing is extremely toxic and must therefore be handled in a special vacuum chamber. In addition, handling the powder is extremely dangerous, requiring a highly skilled operator. This also explains the low level of industry adoption. In the same way that mainframe computers were replaced by cloud data centers, large-format metal printers are being replaced by smaller, cost-effective parallel machines – print farms. Now the industry needs something that's 10x cheaper, 10x more secure, and 10x easier to use.

“If you've already done the math and decided that metal 3D printing isn't profitable, it might be time to do the math again.”

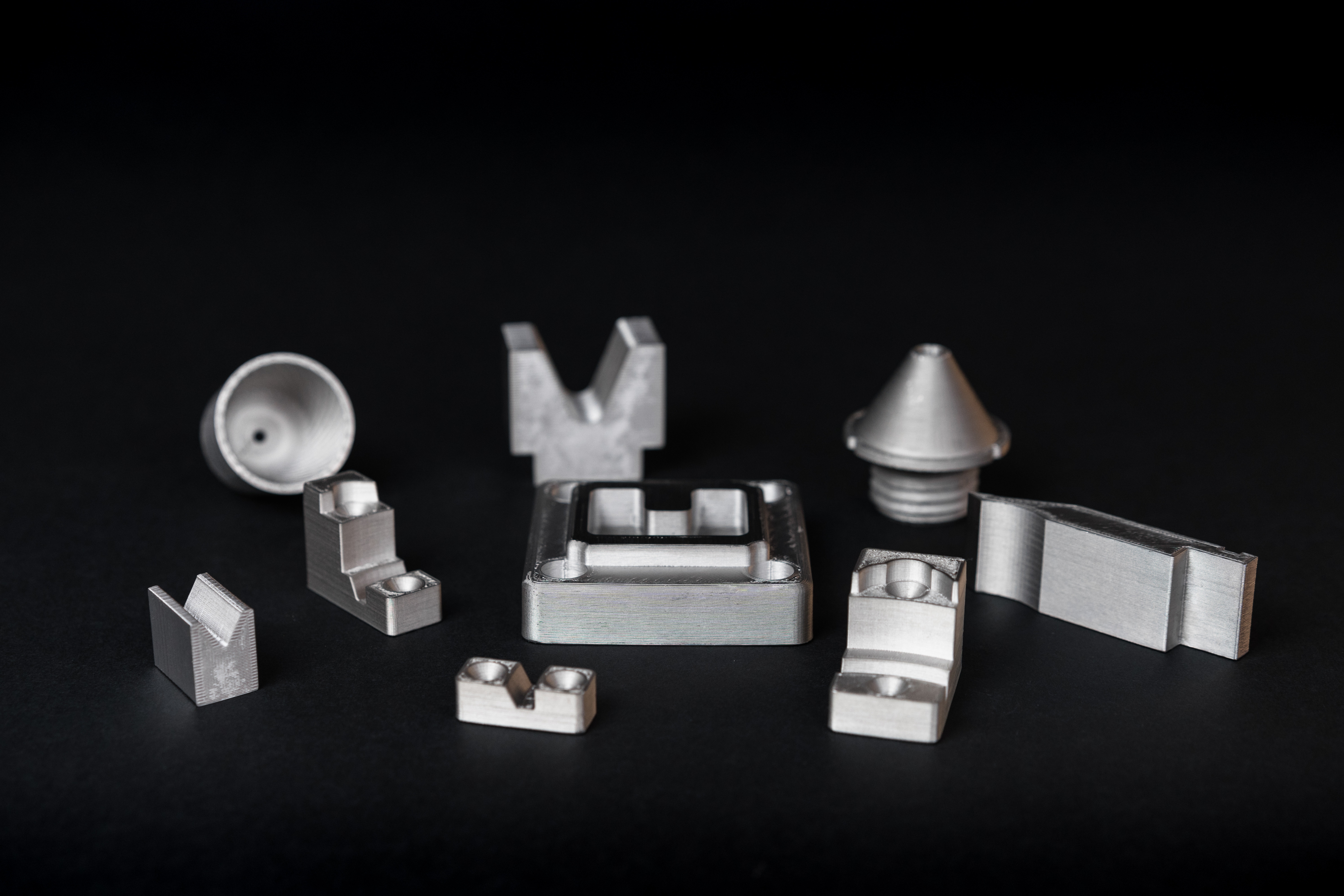

The industry-leading technology of the Markforged Metal X opens remarkable new possibilities for engineers, designers, and manufacturers around the world, enabling them to produce metal 3D printed parts in-house, same-day, at a fraction of the cost. 10x cheaper than alternative metal additive manufacturing technologies—and up to 100x cheaper than traditional manufacturing technologies like CNC or casting. Drastically reduce costs and enable innovation.

Huge potential for cost savings

Companies can use the new technology to significantly reduce production costs for specialized, production-ready metal parts. It is by far the most cost-effective solution for metal 3D printing. With a range of printing materials available, designers, engineers, and manufacturers can design and print strong 3D metal parts overnight, whether they require high strength or weldability. With a starting price of approximately €99,000 for the Markforged Metal X, the overall cost savings cannot be ignored.

“From CAD model to 3D printed metal component overnight.”

The process

The ADAM (Atomic Diffusion Additive Manufacturing) metal printing process ushers in a new era of metal part manufacturing. The revolutionary ADAM technology makes metal part printing safer and easier than previous metal 3D printing processes. ADAM is an end-to-end process that begins with a metal-plastic mixture. This makes it non-flammable, completely safe, and easy to handle. The part formation process builds on existing carbon fiber extrusion technology, in which micro-strands of carbon fiber are bonded into plastic. The part is then printed layer by layer. After printing, the part is sintered in a furnace, the binder burns off, and the powder solidifies into the final, fully dense metal part.

Thermal sintering of parts is well established in the metal injection molding (MIM) industry to produce parts for medical, aerospace, and consumer applications. The sintering step takes place in a furnace and fuses the metal into a dense metal while removing all final traces of the binder. ADAM utilizes well-known MIM materials used in demanding end-use applications. Best of all, the process supports hundreds of metals, including:

By optimizing hardware, software, and materials together, a new standard for incredible surface finish is set. This is important because highly repeatable extrusion (visible as excellent surface finish) is key to dimensional accuracy and fit. The end result is a perfectly sized, pure metal 3D printed part.

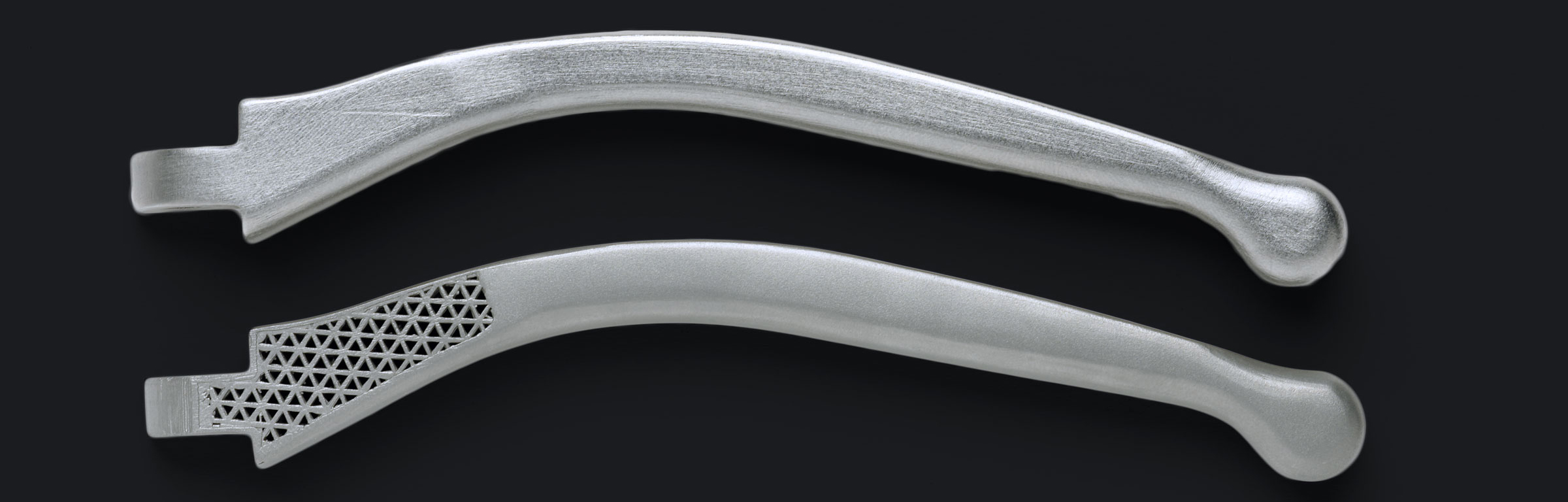

The internal honeycomb structure allows maximum strength to be achieved with minimal material expenditure.

ADAM technology offers manufacturers unique advantages. First, designers can create fully enclosed structures. With previous metal 3D printing processes, an exit hole had to be inserted into the design to allow the metal powder to exit the part, ensuring nothing was trapped inside. Because the binder simply burns off with ADAM technology, parts can be fully enclosed. Second, because manufacturers can create these enclosed designs, they can use complex internal structures to create robust parts that are lightweight and cost less to manufacture. Third, the incredibly low price, combined with the high resolution and quality of the final parts, enables many more use cases than were previously possible.

Stanley Black & Decker

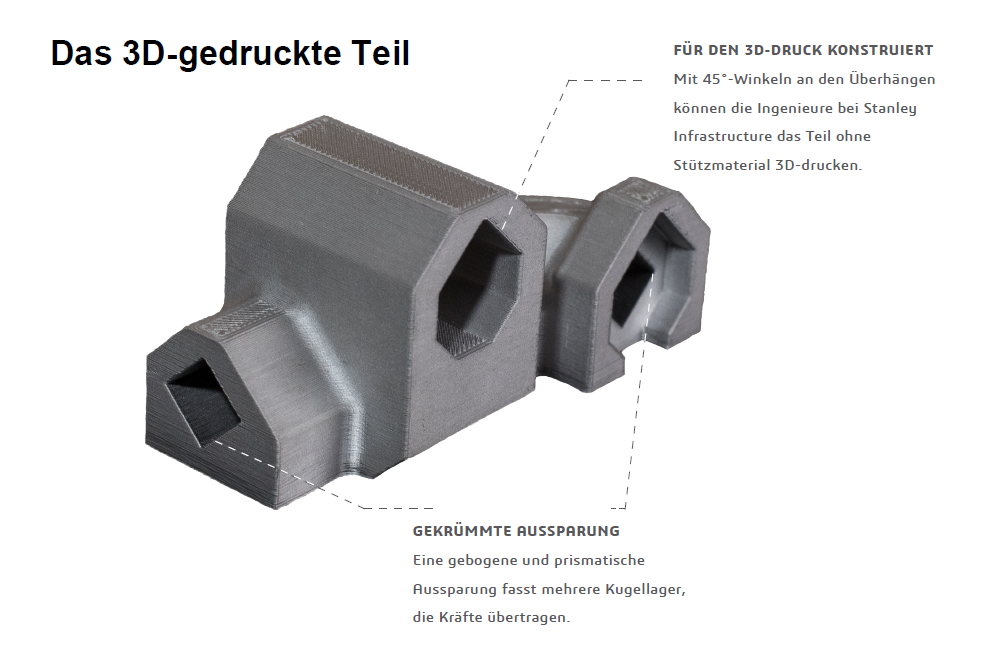

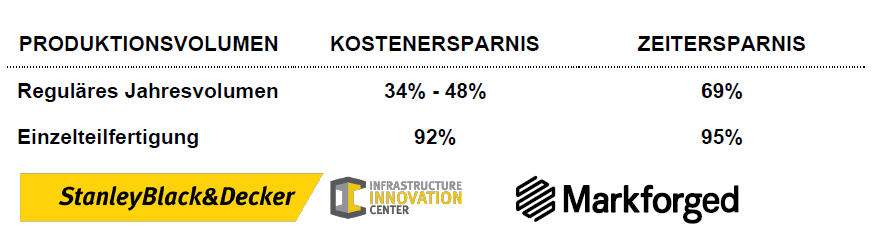

Stanley Black & Decker engineers were looking for a cost-effective way to produce complex, low-volume parts. After exploring metal 3D printing technologies, Stanley Black & Decker's Infrastructure Innovation Center selected Markforged's Metal X additive manufacturing technology to produce reliable, 3D-printed parts and reduce manufacturing costs and lead times.

By leveraging Markforged's Metal X additive manufacturing technology, the Infrastructure team expects to reduce manufacturing costs for two different parts—a drive housing for the PD45 Hydraulic Post Driver and a wheel shaft for the PG10 profile frog mill. Stanley Infrastructure engineers rigorously tested the performance, durability, and lifecycle of each part and approved them as production parts at a fraction of the cost.

By replacing their current manufacturing process with the Markforged Metal X, Stanley Infrastructure saves between 34% and 48% in manufacturing costs and reduces part lead time by 69%. While this is already a significant savings, they can leverage the Metal X even more for single-part manufacturing (in this case, Stanley Infrastructure often produces one-off spare parts for equipment in the field).

Since the existing process only produces parts in series, 3D printing individual parts with the Metal X is 12.5x cheaper and 20x faster than casting and CNC machining.

Reduced complexity

The original drive housing consisted of four components: a cast and machined main housing, a laser-cut cover plate, and two bolts that held the assembly together. Engineers at Stanley Infrastructure worked with Markforged to optimize the part for 3D printing with the Metal X. Instead of the four-part assembly, the newly designed part is 3D printed as a single, continuous piece without support material. This allows for significant savings in manufacturing costs and design time.

According to a Stanley Infrastructure engineer, Stanley can save thousands of dollars a year in this area alone while replicating the quality and reliability of parts they are used to with CNC parts. You can find the detailed user report from Stanley Black & Decker here.

Series production

“What really matters is being able to increase production volumes as quickly as possible” / Elon Musk

It's now as easy as selecting a part, choosing the material, and printing on a fleet of 3D printers across a user organization. From anywhere, around the world. Metal 3D printing farms shorten development time and bridge the gap between prototyping and production, leveraging a cloud-based fleet management solution. There are thousands of printers producing parts around the world—all running with full telemetry, error monitoring, feedback, and analytics. Think of it like a distributed print farm. At Markforged in Boston, over 100 printers run in parallel. Half are dedicated to producing parts for the development of new Markforged 3D printers. 30 3D printers are in long-term testing, and 20 are dedicated to producing sample parts—about 11,000 parts per month.

Another highlight: If you want to print prototypes, use one printer for production or use 100. The number of 3D printers doesn't matter. This is because the 3D printing technology behind ADAM fundamentally reduces costs. You start with a well-known high-volume process (MIM). 3D printing instead of injection molding. Multiple 3D printers controlled by fleet management software. A full stack sintering furnace is designed to rival an injection mold, enabling a print farm of 500-1,000 units.

Conclusion

For thousands of years, humans have been casting metal into molds. Now we've found a better, easier way. The digital age has transformed every industry known to man—music, photography, telecommunications, email, and the internet. However, manufacturing remains largely the same as it was in the 1950s. It's time for mechanical engineering to enter the digital age.

Have you been wondering if your company could benefit from additive manufacturing? Should metal 3D printing be part of your innovation strategy? Would a weight reduction impact the bottom line? Since Markforged's complete metal 3D printing solution, including a sintering furnace and washing station, is available for around €150,000, the Metal X could be the metal 3D printer you've been waiting for. See it for yourself and request your custom sample part.

Request a DEMO component now!

See for yourself how strong the continuous fibers are.

About the author: Richard Elving, APAC Channel Sales Manager for Markforged with over 15 years of sales and business leadership experience, has extensive knowledge of the manufacturing industry, visiting over 4000 manufacturing sites across Northern Europe and APAC for organizations such as Autodesk, Dassault Systemes and SolidWorks, where he has been recognized for exceptional sales success.

The text is translated and adapted from English. Original article:

https://www.linkedin.com/pulse/how-affordable-metal-3d-printing-changing-way-we-make-richard/

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar