Galvanic coating of 3D printed components

Mark3D is often asked about coating components, so we set out to find the best method.

Electroplating techniques are available, and each method offers a solution for a specific requirement. Some are used to protect against harsh conditions such as salt water or chemicals, others to increase the wear resistance of surfaces, and still others for purely aesthetic reasons, which in our case is the primary requirement.

So how does the electroplating of 3D printed components work?

We naturally conducted the tests with our Onyx material. Onyx is widely known for offering one of the best surface finishes available on an FFF printer. With near-perfect Z-axis walls and improved unidirectional roof infill, the results straight from the Markforged printers are already very good. This is important to give us a good starting point.

Our first test consisted of plating some parts directly from the printer without any further processing. The results were satisfactory, and the electroplating company coated the component with a conductive layer using a traditional process before applying the final "topcoat." Fig. 1 shows an example. We can see that the gloss of the chrome plating compensates for the differences in the

Surface quality is further enhanced. It's clear, then, that the initial quality of the "substrate" has a major impact on our finish.

Our next attempt was to chemically etch a part; this altered the surface texture enough to remove the print lines and give us an even better starting point. The results of this technique turned out to be the second-best option.

By far the best result we achieved, as shown below, was with a handcrafted rose gold piece. The finishing process is manual, time-consuming, and drastically increases costs. Nevertheless, the results are outstanding.

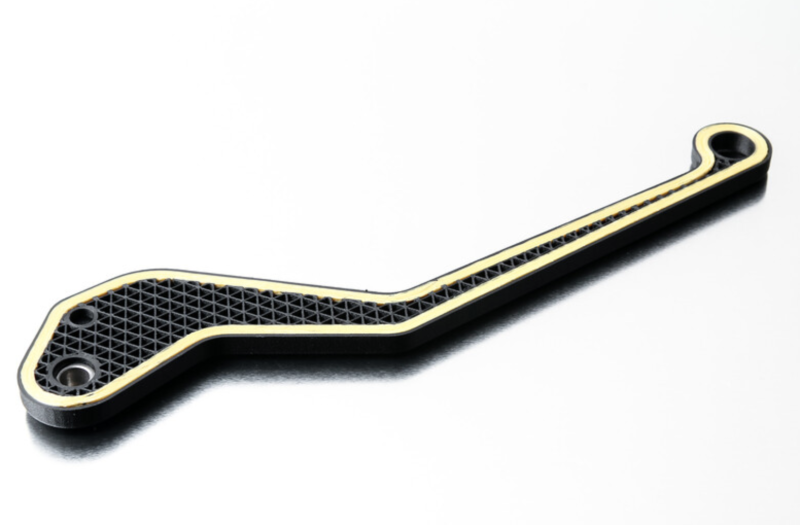

The image shows the interior of the component. The brake lever is reinforced internally with a continuous fiber. The honeycomb structure is also clearly visible.

The substrates (the initial parts) were sanded to remove any impurities, then reworked with a low-quality wet and dry abrasive and sprayed with a special varnish to improve adhesion. The underlying copper layer was then applied, checked again for impurities, and refinished if necessary. The final electroplating process took place on a very smooth copper layer.

It is therefore possible to obtain beautiful, high-quality, electroplated components if necessary. Applications such as custom bathroom fixtures, automotive and aerospace parts, and other highly visible end-use components seem to be the best applications!

Mark3D is happy to provide the names of the companies we used to produce these samples upon request:

Please call 07361 63396 00 or send us an email markforged@mark3d.de

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Leave A Comment