Optimized supply chain using Markforged 3D printing

New wind turbine installations in the US declined in 2021 compared to 2020, but the US still aims to generate 20% of its electricity from wind power by 2030. In contrast, China set a record for wind power capacity additions in 2021. In fact, the number of wind turbines in China grew more last year than in any other country in the past five years.

In the European market, the conflict in Ukraine has significantly increased the collective desire to move away from fossil fuels. Of course, this has done little to curb the EU's short-term demand for oil and gas. In the long term, however, there is an ever-increasing need across the continent (and around the globe) to significantly improve the supply of all components of wind energy. And the world's largest wind turbine manufacturer—the Danish company Vestas – is using additive manufacturing to address the supply bottlenecks that have plagued the wind industry since the start of the pandemic.

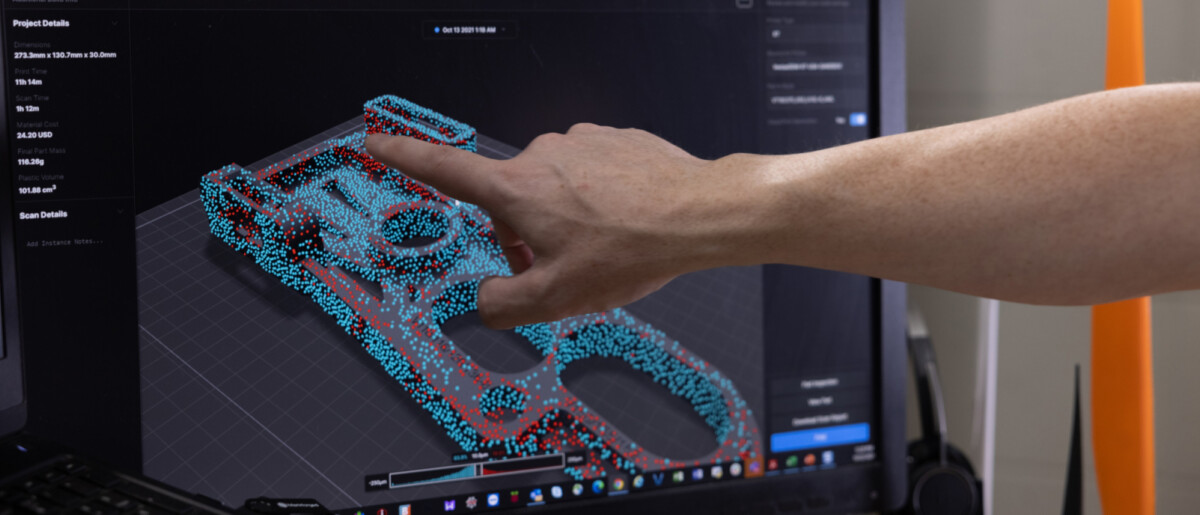

Vestas manages operations spanning the globe (including more than fifteen manufacturing sites) and has experienced firsthand how supply chain disruptions over the past two years can impact a business. Fortunately, in 2021, Vestas launched its Direct Digital Manufacturing (DDM) program, powered by a suite of Markforged products: the X7 and Onyx One 3D printers, the cloud-based Eiger software, and the Blacksmith software system—collectively referred to by Markforged as The Digital Forge platform.

Vestas is an ideal example of what a digital supply chain for renewable energy and additive manufacturing can look like and what it can mean. Jeremy Haight, senior engineer for AM and advanced concepts at Vestas, says:

"Our approach is end-to-end. We deliver the physical item to a variety of locations in near real time. I think that's the closest thing to teleportation."

Although Vestas already has more than 2,000 parts stored in the Eiger software, the company has highlighted two components as particular DDM success stories: top-center (TC) marking tools and lightning tip receptors. TC marking tools are used to ensure that the root ends of turbine blades are properly aligned. Using conventional manufacturing methods, these tools were originally made only from metal and took up to five weeks to produce. Now that Vestas is able to print the TC marking tools on-site using Markforged's nylon-based Onyx material, the production process takes just a few days, eliminates shipping time, and the end result is 85% lighter.

Advantages of 3D printing

Conventional methods for manufacturing lightning rods, used to reduce lightning damage to wind turbines, take at least 12 weeks. Furthermore, conventionally manufactured lightning rods are made of aluminum—perhaps the material most affected by supply chain issues over the past two years. The same part manufactured using AM, however, is made of copper and can be completed in as little as two days. And, as with TC marking tools, one of the biggest advantages of AM technology is the ability to produce the lightning tip receptors exactly where they're needed.

Conclusion

In summary, Vestas is an instructive example for any company seeking to leverage AM to build a digital supply chain for two reasons. First, the company is the leading manufacturer in one of the industries most affected by pandemic-related supply chain issues in the short term. Second, the company operates in an industry that can also have a positive impact on global supply chain issues in the long term by supporting humanity's (very) gradual transition away from total dependence on fossil fuels.

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Leave A Comment