Address Manufacturing Challenges – Whitepaper

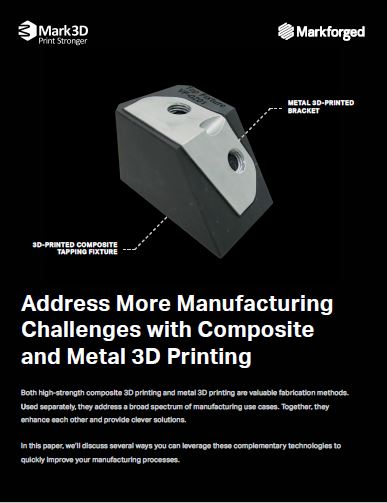

Both high-strength composite 3D printing and metal 3D printing are valuable fabrication methods. Used separately, they address a broad spectrum of manufacturing use cases. Together, they enhance each other and provide clever solutions.

In this paper, we’ll discuss several ways you can leverage these complementary technologies to quickly improve your manufacturing processes.

Fill out the form on the right to get your whitepaper now.

Fill out our secure web form below to download the whitepaper.

Justification is getting easier

Recently the argument in favour of a good return on investment for 3D printers has certainly become stronger. This has enabled more and more people to find good 3D printing cost justifications and thus fund machines. Meanwhile 3D printing is advancing into the realm of production, both in terms of work-holding and custom end-use parts. So whilst the value of a printer didn’t used to be blindingly apparent at first, executing the calculations now tells a different story.

In production and manufacturing, productivity is directly tied to revenue and performance. Therefore whilst the price of a production quality 3D printer may sound steep initially, you can save lots of money. It is possible to eliminate many of the traditional manufacturing costs and find a strong ROI. Examples of this can be found in work-holding, jigs and fixtures, initial prototyping, and special tooling costs.

Markforged composite printers uniquely embed continuous reinforcing fibers — carbon, fiberglass, or Kevlar® — to print parts up to 23 times tougher than ABS, while Markforged metal printers fabricate stainless steel parts. Each printing technology leverages the advantages of additive manufacturing to create parts suited for different aspects of the manufacturing process. By understanding their strengths, you can maximize the utility of high-strength 3D printing in your operation.

Mark3D can offer help in working out the cost of 3D printing and can be reached on 0800 193 3650.