Opening Up CNC Bandwidth at a Job Shop with 3D Printing

Recorded webcast from May, 2018

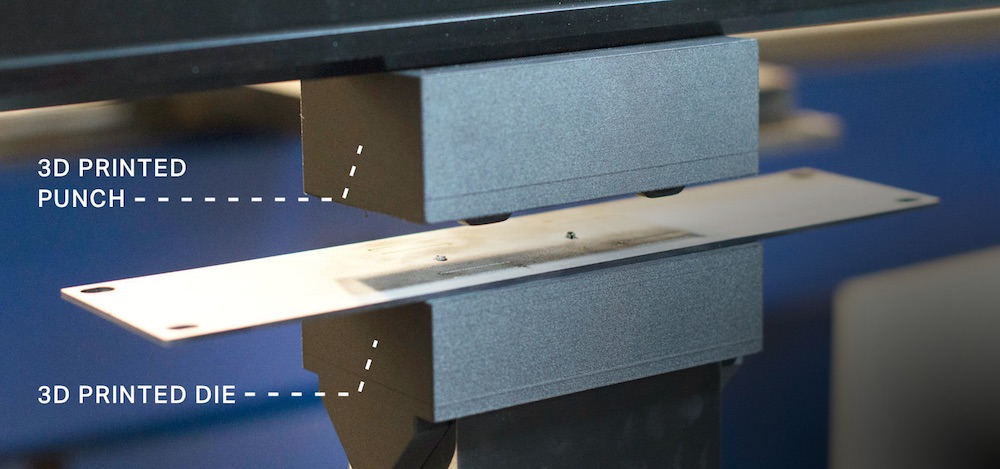

Phil Vickery, President and Owner of Centerline Engineered Solutions, goes out of his way to help clients. But machining a punch and die for a low-volume 14-gauge steel part made the job prohibitively expensive.

Join us for a live conversation with Phil to learn how he leveraged industrial 3D printing to:

Presented by Daniel Leong

Daniel Leong is the Lead Content Engineer at Markforged. Originally from Idaho, he graduated from Olin College of Engineering with a degree in Mechanical engineering. At Markforged, Daniel works on bridging the gap between traditional machining and 3D printing.

Fill out our secure web form below to watch the webinar.

Learn more about applications with plastic printing with continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.