The Future of Manufacturing: How Digital Workflows Are Transforming Industry 4.0

From faster lead times to reduced costs, discover how digital manufacturing workflows are changing the way businesses compete.

- Manufacturers are cutting lead times by up to 80%

- Adoption barriers are shifting from hardware cost to skills and culture.

- Digital workflows are becoming a strategic differentiator.

What’s Changing in Manufacturing

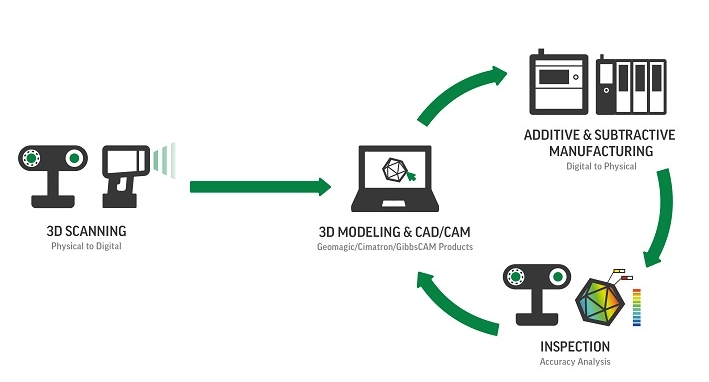

Capitalising on the closed loop offered by 3D Scanning and 3D printing can drive down costs in manufacturing. With potentially limitless applications for reverse engineering and the adoption of plastic and metal printers modern manufacturing companies aren’t short of places to start.

Throughout time, manufacturing companies have needed to adapt to survive and in today’s economic climate it’s set to be no different, writes Ian Weston, Managing Director at Mark3D UK. Constant demands from management to identify and drive down costs means today’s engineers must be more adventurous and creative to realise valuable cost savings.

Many in the manufacturing sector, especially in engineering, believe “the easy wins went long ago”. However, I’m not so sure. Over the last five years we have seen a number of agile, entrepreneurial, high-tech companies start up, or morph from their current position, to offer today’s engineers a host of modern technology that can help drive down costs. Known as “Industry 4.0”, engineers have at their fingertips some particularly powerful tools, there’s a vast range of 3D scanners for capturing highly accurate complex data, some excellent polymer, hybrid and metal 3D printers and the integration of AI across all of it. It’s an exciting time to be an engineer.

Scanning and printing for engineers has improved tremendously in recent years. When combined the technology offers a closed loop from reality > digital > physical, where 3D scanning digitizes real-world objects into 3D models (point clouds, meshes, CAD-ready files), an engineer makes whatever digital changes are needed and 3D printing takes the digital models and turns them into physical parts. Together, they form a closed loop: scan → modify → print → validate (with or without AI).

The opportunity for excellent return on investment (ROI) is there, if production engineers know where to find it. Simply borrowing a scanner or printer from the design office and expecting immediate results giving huge cost savings is not realistic. Whilst the scanners are similar, design office printers use different materials and technology compared to those used by engineers.

Print savvy engineers know that 3D printing is far more valuable to businesses outside of the design office, rather than within it, typically realising an ROI in around three months. However, even with affordable printers, with strong materials and predictable results, it often struggles to be taken seriously in the boardroom. While early 3D printers did a great job in raising awareness of the technology, they had an equally adverse effect because of the items people chose to print with them. Green men and games characters fail to cut it in the engineering board room.

A solution for your average Joe

Imagine you are Joe. Joe is a great engineer who takes a lot of pride in his work but he’s very busy. He only has the budget for essential things to keep his factory running and for supporting his colleagues with engineered items. He dreams of speeding up production with new fixtures, making machines go faster by removing weight from metal parts, and reducing the cost and lead times associated with outsourced components. There are many things Joe knows he should fix but they are all items on an ever-growing wish list, that he’ll never get to address.

There are thousands of “Joes” in the world. While some of them have seen the light and invested in quality scanners or thoroughbred 3D printers, there are many who are too busy, are restricted from investing by their business owners, or simply don’t understand what’s available to them. However, high resolution scanners and 3D printers that offer strong base materials along with the ability to add a second continuous fibre filament, such as carbon fibre, can be purchased for less than the cost of a small van.

How Scan-Print-Validate Transforms Manufacturing

3D scanners come in all shapes and sizes and use a varying range of data capture technology. You can choose from around 6 or 7 different technologies, and it will soon become apparent which one suits your requirements. Invariably todays multi-skilled engineer will select a laser scanner, or a handheld structured light scanner. It’s also worth noting that contact arms with a touch probe perform similar functions but are very much more focussed on the metrology side.

Laser triangulation scanners project a line or point onto the object, and a camera measures the angle of reflection to calculate depth. They offer high accuracy (tens of microns) and are good for fine details. The are often found in industrial inspection, reverse engineering, dentistry and cultural heritage.

Handheld structured light scanners shine light patterns (stripes, grids) onto the object and cameras record how the patterns deform. They are fast with acceptable resolution and capture entire areas at once. Inbuilt PC’s, the lack of cables, the fact they don’t require ‘markers’, and the overall flexibility found with some of these scanners suits engineers who are on the move or never know what sort of problem they’ll get asked to solve.

Nowadays 3D printers make plastic parts that are stronger than aluminium, weigh dramatically less and cost a fraction of the price. The possible uses are almost endless for anyone who invests in the technology. It’s possible to print strong robot grippers and reduce the weight of the part by one third. This weight reduction allows the robot to increase its payload by the same amount or move quicker in its operation, depending on operator preference.

They also print machining fixtures that can withstand the harsh environments inside computer numerical control (CNC) machine tools and drilling jigs can be printed in a fraction of the time it takes to sub-contract one. These fixtures are as accurate as the current “traditional” method.

Entry level machines, known as desktop printers, are very popular with many organisations purchasing multiple units. These machines offer the full range of materials required by today’s engineer. They use a 240v plug and sit on the desk in the engineering department, running 24/7. Programmes can be sent to the printer remotely once an accurate time/cost analysis has been performed via the associated software.

Larger industrial type machines now include laser measurement systems to check and automatically correct parts mid-print, giving constant loop feedback to make necessary corrections. They offer flame retardant and electrostatic safe materials for specialist applications and regularly create products that are ten times cheaper than CNC machined parts. Because of the cost, practicality and logistical benefits, we see printers appearing in traditional sub-contract machine shops as business owners react to the changing dynamics.

As printing at the point of need matures, we’re now seeing the worlds military take fleets of printers with them on exercise, drop them out of planes on parachutes and add them as part of the standard cargo on ocean going vessels. Although viewed as a threat by the defence supply chain they shouldn’t be, these machines are there to make a ‘good enough part’ until a new part supplied by the OEM can be delivered. Scanners and printers are keeping the military moving.

Imagine a world where centrally controlled engineering departments print parts, on demand, in remote facilities throughout the world and local staff fit them

New materials

Today, there are hundreds of examples available to demonstrate parts in end-use situations. These “fit and forget” parts allow those outside of engineering to carry on their daily routines oblivious to the fact that their mission critical application has printed parts within it. Because of the range and quality of new materials, it can be very hard to tell which parts are printed and which are made traditionally.

A range of easy-to-use metal printers are available, and machines that offer both polymer and metal have recently appeared on the market too. These cost less than the price of a decent CNC machine tool and offer an ever-growing range of materials and regular advances in functionality, with secure encrypted software too. The technology is now both affordable and usable for today’s average Joe. It has a very short learning curve and requires no specialist skills, so uptake is expected to grow exponentially. In a very short space of time, we will see an initial scan modified in CAD and then passed to a metal printer. The use of hybrid (plastic and metal) engineered solutions will take off at quite some pace too.

In many situations traditional manufacturing techniques, which have been used for centuries to create low-volume components, can no longer compete. I believe that eventually every company that is serious about manufacturing will have added a 3D composite printer to the plant list and most will add metal too, after learning on plastic. Engineers will have access to their machines from anywhere in the world and will think nothing of setting off print jobs across a wireless connection remotely. This is truly the start of a global transformation in the manufacturing process.

Barriers for Adopting 3D Scanning and Printing & How to Overcome Them

Despite their proven benefits, 3D scanning and printing often face resistance when organizations consider adoption. The most common concerns are that the technology is too expensive, that the learning curve is steep, or simply that “we’re not ready.” These perceptions can stall innovation, keeping companies reliant on slower, less flexible processes while competitors move ahead.

A practical way to overcome these barriers is by leveraging external service providers, such as scanning and printing bureaus. These partners allow businesses to access high-quality equipment and expertise without the upfront investment. By outsourcing initial projects—whether it’s reverse-engineering a legacy part, creating a prototype, or performing a quality check—companies can experience the benefits firsthand while minimizing risk.

This bureau-first approach also helps teams build internal knowledge and confidence. Engineers see the results, understand workflows, and begin identifying where in-house capability would deliver the most value. Over time, this smooths the transition toward purchasing their own scanners or printers. Instead of a leap into the unknown, adoption becomes a step-by-step process, guided by real-world experience. In this way, barriers transform into opportunities—allowing companies to innovate at their own pace while preparing for full-scale Industry 4.0 integration.

“The hardest part isn’t the printer, it’s changing mindsets.”

The Skills Shift: People at the Heart of Industry 4.0

Industry 4.0 is often described as a technological revolution, but at its core, it is a human transformation. As automation, data analytics, and digital tools reshape manufacturing, the most valuable asset remains people. Engineers and technicians are no longer expected to master only mechanical processes; they must be digitally fluent, comfortable working with software, sensors, and smart machines. This shift calls for hybrid skills—combining traditional engineering knowledge with data-driven problem solving and digital design capability.

Far from replacing workers, emerging technologies like 3D scanning and additive manufacturing are empowering them. Scanning provides teams with accurate digital models, making it easier to reverse-engineer parts, validate quality, and accelerate design cycles. Printing, in turn, allows rapid prototyping and flexible production, reducing bottlenecks and encouraging collaboration across functions. Together, these tools act as force multipliers, amplifying creativity and efficiency while freeing skilled staff to focus on higher-value tasks.

The skills shift of Industry 4.0 is not about machines taking over, but about people and technology working in synergy. Success will depend on continuous learning, adaptability, and fostering a culture where digital fluency becomes as fundamental as technical expertise.

In Conclusion

Industry 4.0 is no longer just a buzzword—it’s here, reshaping how products are designed, produced, and maintained. Across manufacturing, digital tools are becoming the standard, not the exception. Among them, 3D scanning and additive manufacturing stand out as more than niche technologies; they are fast becoming the foundation of future-ready workflows. Scanning enables precise digital capture of parts and environments, while printing transforms those models into tangible solutions, whether for prototyping, tooling, or production.

Together, this “scan-print loop” shortens development cycles, reduces waste, and unlocks agility that traditional methods can’t match. It empowers engineers to innovate faster and adapt in real time. The shift is underway, and those who delay risk falling behind. Manufacturers that embrace the scan-print loop today will not only streamline their operations but also set the pace for tomorrow’s industry—leading with agility, resilience, and vision.

Learn more about the technology driving the Future of Manufacturing

How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

Request a demo!

Feel the strength of the 3D printed parts for yourself.