Markforged Onyx ESD-safe printing material

What is Markforged Onyx ESD-safe printing material?

In the electronics industry, protection against electrostatic discharge (ESD) is of utmost importance. ESD can damage sensitive electronic components and cause costly failures. The solution? Markforged Onyx ESD-safe printing material.

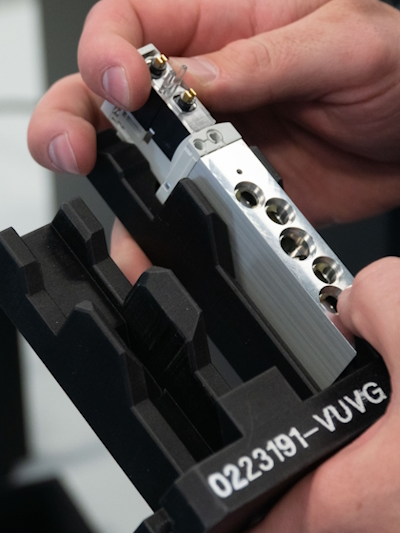

Markforged Onyx ESD-safe printing material is ideal for the production of components that must effectively absorb electrostatic discharges. The use of ESD printing material is particularly advantageous for housing parts in electronics production.

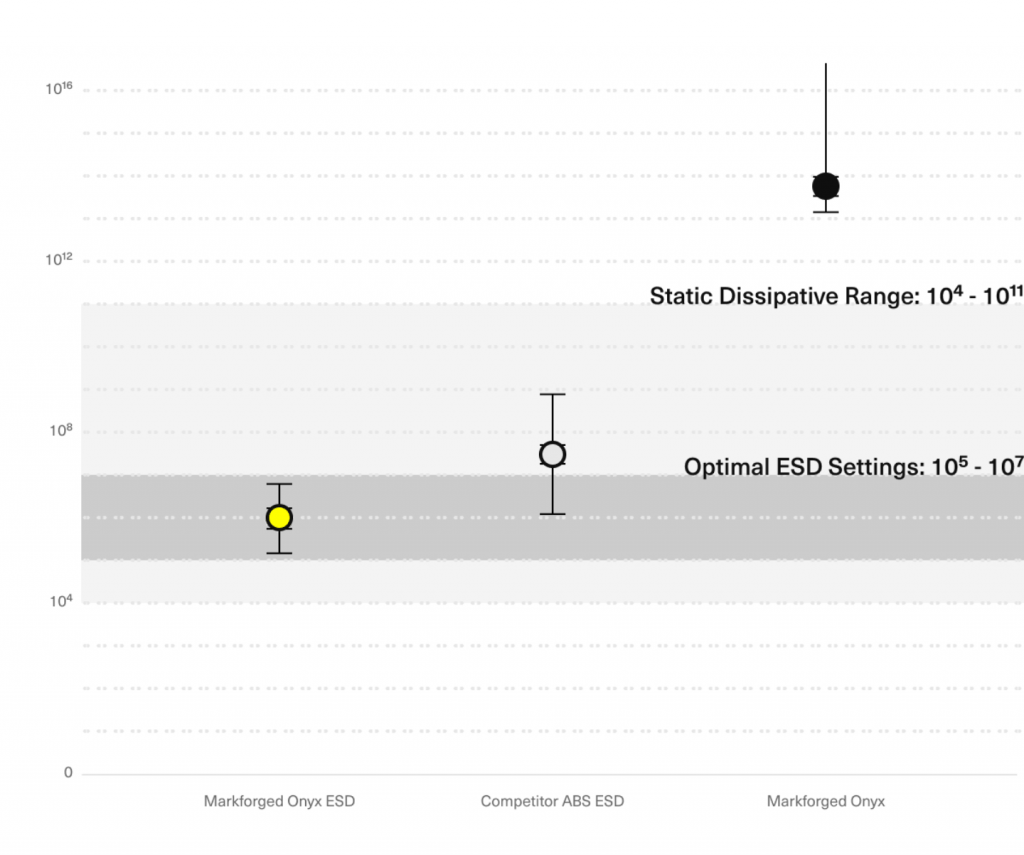

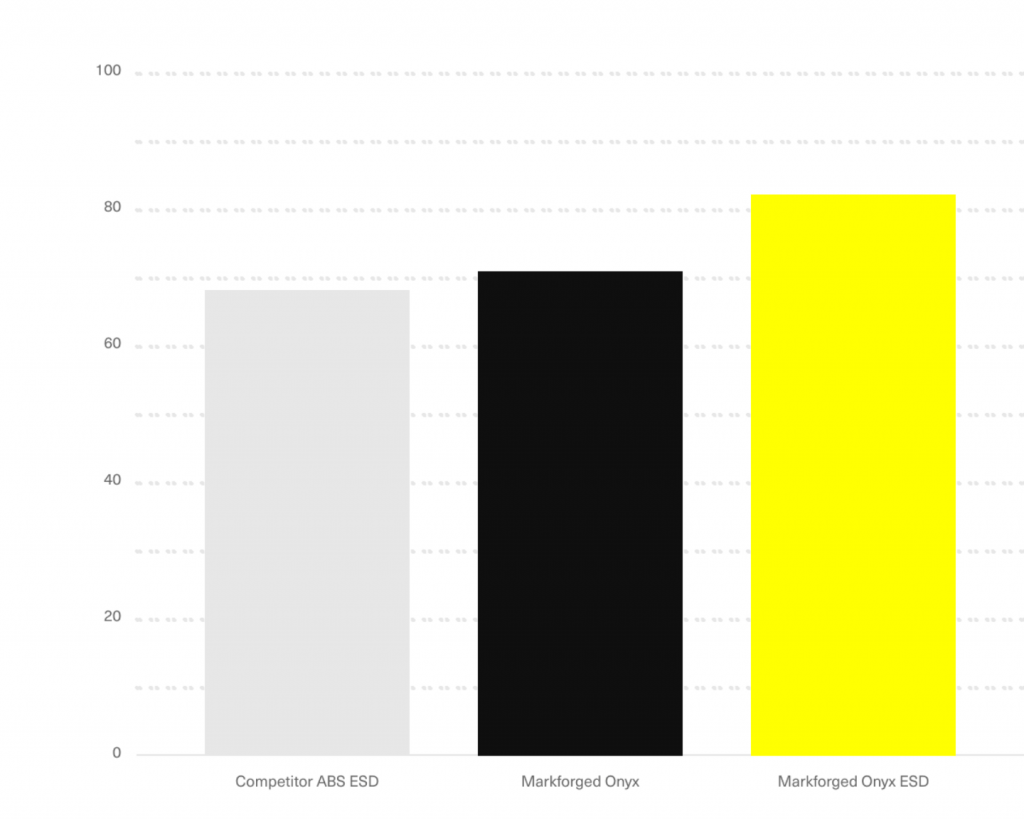

It is precision-engineered for an extremely low surface resistance range and meets the ESD protection requirements of the most stringent manufacturers. It also offers the same benefits as the renowned Markforged Onyx material. In fact, it is even stronger and stiffer than Onyx with a similarly impeccable surface finish, making it the ideal material for innovative applications.

Practical report:

FESTO relies on 3D printing with Markforged in electronic component production

FESTO is a leading global provider of automation technology and employs more than 20,000 people in over 60 countries.

The high manufacturing costs of the diverse equipment had to be reduced. "Simple" 3D printing wasn't enough. A true manufacturing system was needed that could reliably and repeatably produce mechanically resilient components.

In addition, applications for electronic component manufacturing had to be able to be manufactured reliably using ESD-safe printing materials.

Markforged Onyx ESD meets the antistatic requirements of the EMS industry

Electronic components can easily be destroyed due to electrostatic discharge.

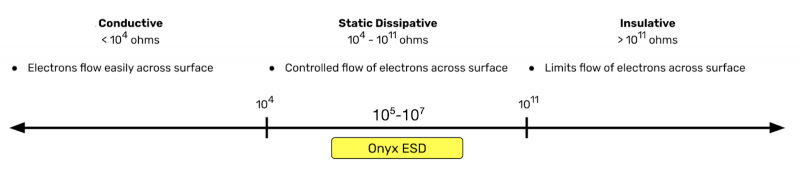

With Onyx ESD and the exceptional print quality of Markforged's X-Series, you can now print tools, fixtures, and enclosures that meet ESD protection requirements. The surface resistance of the Onyx ESD is in the middle of the static dissipative range at 105 to 107 ohms.

Surface resistance

105-107Ω

Flexural strength

83 MPa

Request a DEMO component now!

See for yourself how strong the continuous fibers are.

Frequently asked questions about ESD-safe 3D printing (FAQ)

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged X-Series printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: info@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.