Oil & Gas Companies

Reduction of changeover times and increase of plant throughput through Markforged technology

Challenge

The manufacturing department of a Canadian energy provider faced the challenge of developing a device for automatically loading large fiber optic cable reels. This was necessary to significantly reduce changeover time and increase plant throughput. The replacement reels weighed between 50 kg and 105 kg, making them too heavy to transport.

The cost of manufacturing the custom parts for the machine was prohibitively high. "These one-off parts typically have a lead time of three to six weeks," said Phil M., a senior mechanical designer. Commissioning the machine was expected to increase the plant's throughput by 15%. The company faced a loss-making situation—either pay the additional cost of building the machine or forgo the increase in plant throughput.

Solution

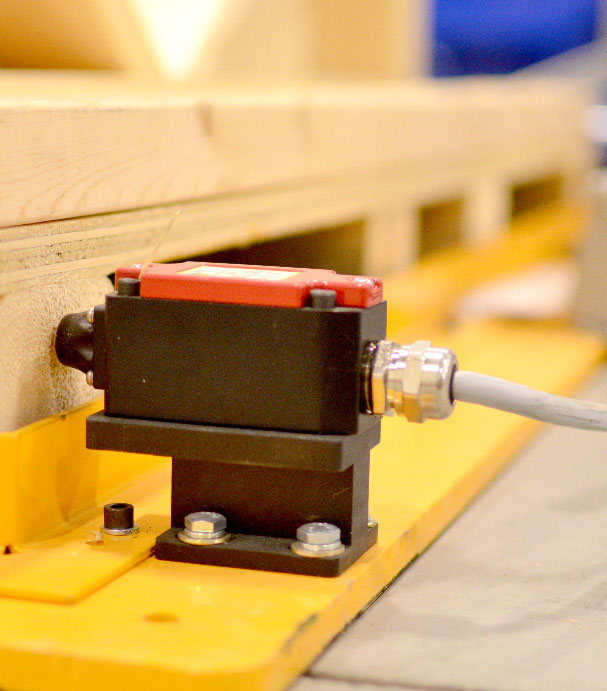

Phil and his team had heard about Markforged and realized they could print several of their custom aluminum parts on a Markforged 3D printer. He demonstrated the potential savings and purchased a Markforged Mark Two—a desktop 3D printer capable of printing with continuous filament. The team began printing parts for the machine and discovered they could do so at a significantly lower cost. There are now 53 3D printed components for the handling machine, including fuse covers, laser sensor mounts, mechanical covers, bump stops, motor mounts, and more. In addition, the team has been replacing machine parts that broke during testing or needed adjustments with Markforged 3D printed parts overnight. These spare parts are critical to keeping the machine's development on schedule.

The company leveraged the added value of Markforged technology and reinforced components with continuous fibers for added strength. Phil estimates that about 50 percent of the printed parts were reinforced with Kevlar®, HSHT glass fiber, or carbon fiber. "For impact-loaded parts, we chose Kevlar® or HSHT glass fiber, and for parts that needed stiffer, we chose carbon fiber," says Phil. The design team saved €19,000 by replacing aluminum and sheet metal parts with 3D-printed parts on the handling machine alone.

At a glance

Customer testimonials

“Every month the handling machine is not in operation, we lose over 15% of the total plant throughput.”

– Phil M., Senior Mechanical Designer

“People were blown away by the overall quality; they never thought they would see printed parts applied to machines that would actually be used in a production environment.”

– Phil M., Senior Mechanical Designer

Request a DEMO component now!

See for yourself how strong the components are.

Looking to the future

The Markforged Mark Two has since attracted a lot of attention from engineers across the company. "People are now starting to realize that you can prototype faster and iterate faster," says Allan C., an electrical engineer at the company. At first, other employees were concerned about the time it would take to operate the printer, but Phil had no concerns. "It takes me less time to set up the printer than it does to create a purchase order to source the part externally," says Phil. Originally, only three engineers and designers used the 3D printer, but now it is used across departments. The printer has become a center of attention within the company: "When people tour the factory, they now point to the printer as something cool and innovative," says Phil.

Learn more about the opportunities for the oil & gas industry!

36 percent of global oil and gas (O&G) companies are already using or intend to use additive manufacturing (AM), according to a recent global survey by EY. Find more information on the topic here: