Customized solutions for aircraft cabins

at Cabin Management Solutions (CMS)

Founded in 2019, Cabin Management Solutions (CMS) is a small, privately held cabin management and entertainment systems company in Conroe, Texas.

CMS works with aircraft maintenance, repair and overhaul (MRO) companies and private owners to design and implement cabin control and entertainment systems for luxury private and corporate aircraft. The company was founded to provide a cost-effective, quick-turnaround alternative to the long lead times and high costs associated with maintaining, upgrading and replacing cabin management systems.

Although CMS is relatively young, two of the founders, Jeff Pike and Jeff McCormick, have over 35 years of combined experience in the aviation field. The company has quickly earned a reputation for its fast time-to-market, the high quality of the products it delivers and its rigorous testing and certification procedures. The CMS team attributes much of its success to the decision to consolidate the majority of product design, development, manufacturing and certification under one roof at its East Texas headquarters.

The challenge

"The Markforged 3D printers have helped us to be on a par with the big players in the industry." - Jeff Pike, Deputy Head of Technology, CMS

CMS is often commissioned to replace or repair obsolete cabin systems in luxury jets. Many projects involve discontinued models and components that were previously produced by manufacturers that no longer exist. For most of these projects, CMS has to manufacture high-quality parts from scratch in small quantities. These range from reading lights, thermostats, switches, USB chargers, custom brackets to entertainment screens and anything else you need. Many of these finished parts are later visible, so maintaining and caring for their upscale aesthetics is almost as important as ensuring functionality.

Custom-made products can be time-consuming and labor-intensive to produce. They are also quite complex as they often require the adaptation of new designs to existing layouts. It is not uncommon for customer requests to change during production. Therefore, the CMS team often needs to be prepared for last-minute changes. Most importantly, all aircraft materials and parts must be thoroughly tested and traceable in order to receive Federal Aviation Administration (FAA) approval.

At a glance

The solution

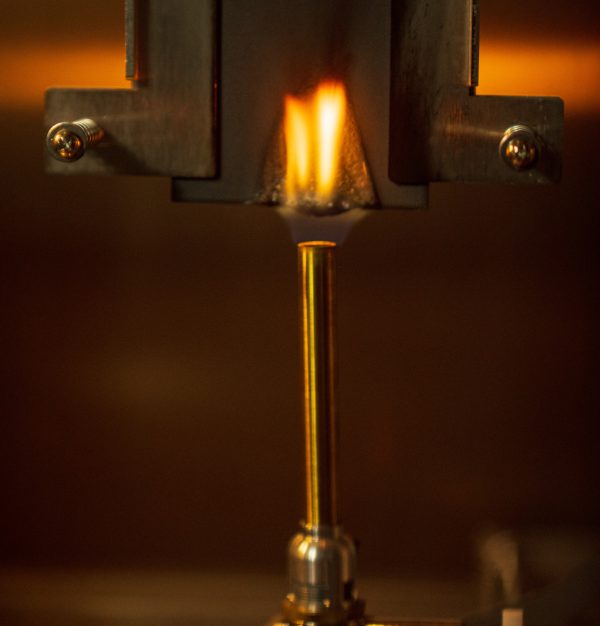

CMS uses Onyx FR to deliver customized parts that are high-strength, lightweight and flame-retardant.

Shortly after founding CMS in 2019, the team purchased two Markforged Industrial X7 3D printers. They immediately recognized the value of 3D printing compared to traditional manufacturing processes and materials. Additive manufacturing allowed CMS to keep the majority of manufacturing in-house, rather than outsourcing production as is often the case when using conventional methods. This has brought huge benefits to the company in terms of the number of orders and speed of execution. "Other 3D printers don't produce such a high-quality surface, which results in additional post-processing that the CMS team can save by using the X7," says Pike.

CMS prints all parts on its two Markforged X7 printers using Onyx FR, a UL 94 V-0 certified flame retardant nylon filled with carbon short fiber. With Onyx FR, CMS delivers customized parts, such as aftermarket parts for in-flight entertainment, that are high-strength, lightweight and flame-retardant.

To meet the specific needs of its luxury-minded customers, the team then adds an extra level of customization through overlays that mimic upscale cabin finishes such as gold electroplating, wood veneer and more. This ensures that the final product meets FAA regulations while exceeding customer aesthetics and expectations.

On one particular aircraft, the CMS team printed at least 100 different parts with the X7. These included around 29 light switch panels, a cabin climate controller, latches, release buttons, USB-C and drop-in USB-A chargers, adjustable touchscreen mounts and much more. Most of these printed parts were then electroplated with gold-plated bezels to match the cabin's existing interior design. The result was more durable parts that look and feel just as high quality as the originals.

Request a DEMO component now!

See for yourself how strong the components are.

"In the aerospace industry, quality and short-term adaptability are crucial for success. Markforged delivers more than that."

- Jeff Pike, Deputy Head of Technology, CMS

The future

Big plans

CMS has big plans for the future, especially with the recent release of two new materials by Markforged: Onyx FR-A and Carbon Fiber FR-A. Both materials come with full material traceability and are undergoing qualification on the Markforged X7 printer as part of a program conducted by the National Center for Advanced Materials Performance (NCAMP), one of two FAA-authorized entities to qualify materials for flight operations. Once this process is complete, CMS will be able to use the data to bring printed parts into critical applications with confidence.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.