Special Offer

Renowned for its ability to print stronger than Aluminium the Markforged Mark Two has always delivered a great ROI for Engineers. Now, with the help of a Markforged promotion, Mark3D can help make that ROI even stronger!

In the past Aluminium has often been the material of choice for prototypes, jigs and fixtures, welding fixtures and the like due to its low cost, ready availability and ease of machining. However, when you take into consideration the associated tooling costs, set up and manpower required it can often make low volume or complex machining using Aluminium too expensive.

The Markforged range of 3D printers are designed to make it hassle free to create a variety of prototypes, fixtures, and one-off parts using 3D printable plastics. They are strong, tough, and stiff — and especially well-suited for checking shape and fit, and making fixtures, end of arm tooling and low volume production parts.

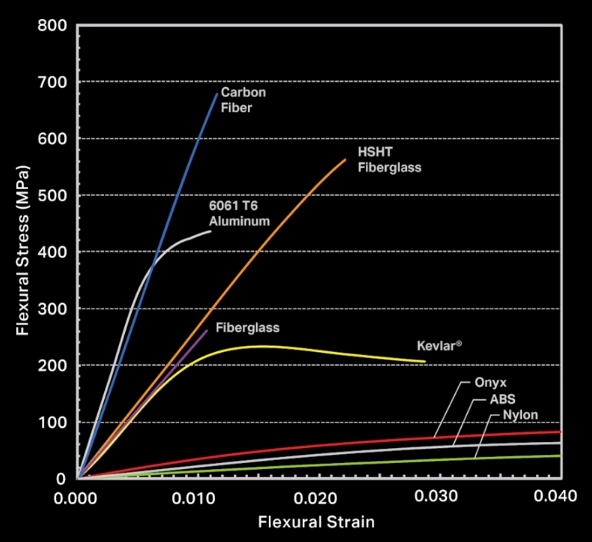

Print materials include Onyx, Nylon and Fibre Reinforced Plastics such as Carbon Fibre, Kevlar and Fibreglass. The chart to the right shows how these compare with Aluminium for strength, toughness, stiffness and environmental resistance.

In our recent blog post Carbon Fibre delivers high end strength for industrial parts we show how now more and more companies are turning to a 3D printed continuous carbon fibre composite that can deliver industrial strength parts on the same day – at a fraction of the cost. For years they had been forced to accept a trade off between strength, time and affordability, compromising on strength and using parts made from conventional polymers, which are just not up to the job in a manufacturing environment.

A college in the USA, 3D printed a chain link made out of nylon plastic reinforced with carbon to test just how strong they could print. Watch the video to see the chain lifting the equivalent of a 10 tonne cement lorry before breaking the strain at 22,000lbs of force.

But it’s not just about being able to print stronger but also more cost effectively using 3D printing technology and Fibre reinforced plastics. In the example below you can see the difference in material and associated costs involved in producing the same part using 3D printed reinforced plastic versus aluminimum.

Justification is getting easier

The argument in favour of a good return on investment for 3D printers has certainly become stronger in the last couple of years. More and more people are now able to find good 3D printing cost justifications allowing them to fund machines. Meanwhile 3D printing is advancing into the realm of production, both in terms of work-holding and custom end-use parts. So whilst the value of a printer didn’t used to be blindingly apparent at first, when you run the calculations now, it tells a different story.

In production and manufacturing, productivity is directly tied to revenue and performance. Whilst the price of a production quality 3D printer may sound steep initially, you can save alot of money. It is possible to eliminate many of the traditional manufacturing costs and find a strong ROI. Examples of this can be found in work-holding, jigs and fixtures, initial prototyping, and special tooling costs.

In our ‘Economics of 3D printing’ whitepaper we outline the steps you can take to calculate your return on investment. Download it and run the calculation for yourself now.

Learn more about applications with plastic printing with continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.