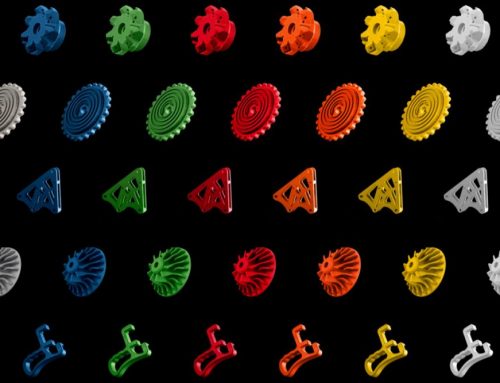

“The components made of the base material onyx have proven to be very wear-resistant and break-proof even under extreme conditions. They can therefore also be used in the sandblasting sector without hesitation. Compared to milled components, a weight reduction of over 60% has been achieved. The lead time for production is now only a few hours”. – Marc Krause from BMF GmbH

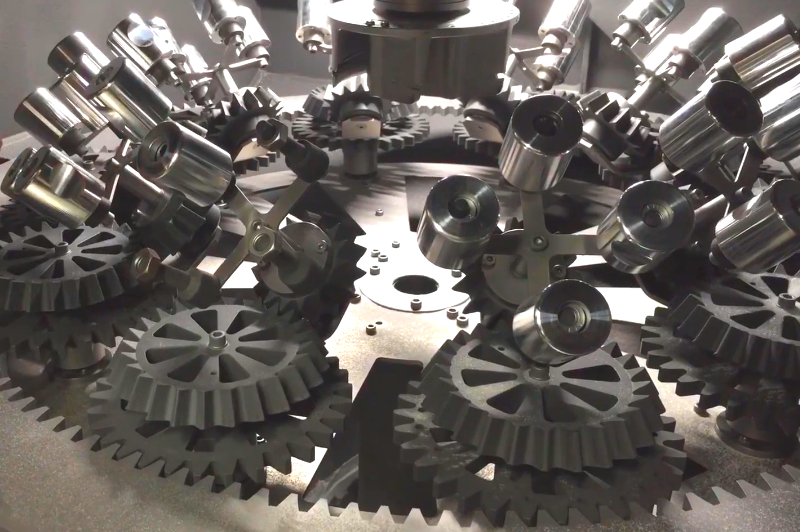

The Smart Surface Control technology developed by BMF GmbH from Chemnitz, Germany, requires a large number of different components, some of which require complex manufacturing processes. Until now, this has required a long production lead time and costly warehousing.

In the meantime, a large number of different parts for the Twister and Tornado are produced on several Markforged 3D printers, as required.

Request a demo!

Feel the strength of continuous fiber for yourself.

Learn more about 3D printing continuous fibres!

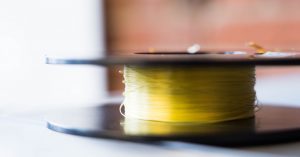

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

Leave A Comment