Metal 3D printing at Stanley Black & Decker

The component

The STANLEY PD 45 is a hydraulic post-hole driver with high efficiency. In order to actuate the hydraulic drive mechanism, the device uses a group of ball bearings to transfer the pull-off force into the hydraulic actuator. The actuator housing holds these bearings in series to transmit the tensile force around a bend. Each housing is tested each time the operator operates the trigger.

Design changes

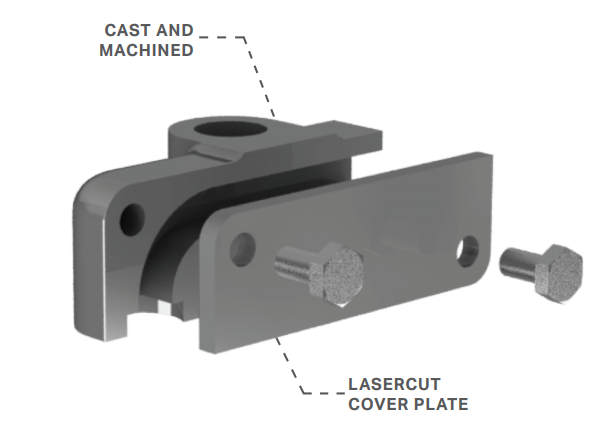

Original component

The original actuator housing consisted of four parts – a cast and machined main housing, laser cut cover plate, and two screws for securing the housing assembly together.

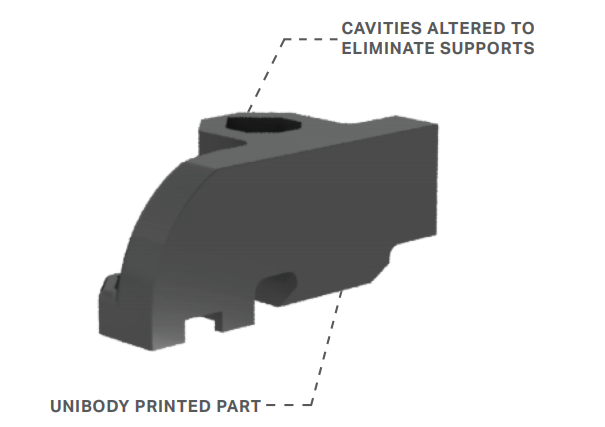

MARKFORGED component

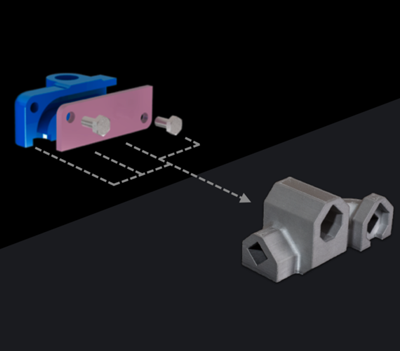

Stanley Black & Decker’s engineers redesigned the part to print on the Metal X. Instead of a four-part assembly, the redesigned part is printed in one piece without carrier material.

The component in the video

Request a demo!

Feel the strength of continuous fiber for yourself.

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.