Why 3D printing with Markforged?

INDUSTRIAL 3D PRINTING

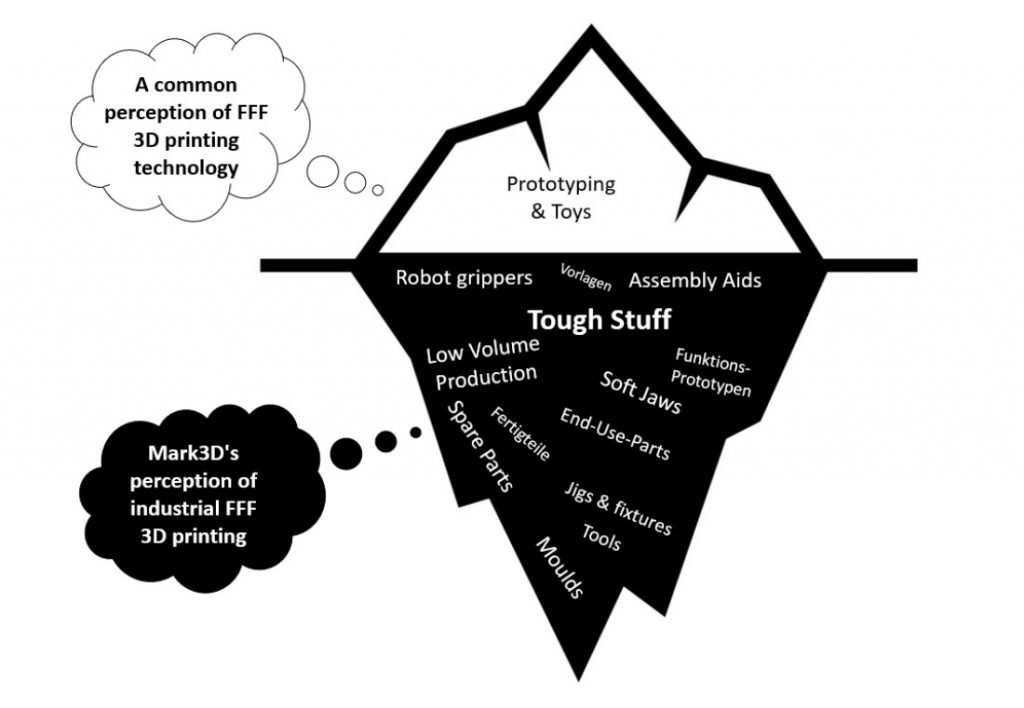

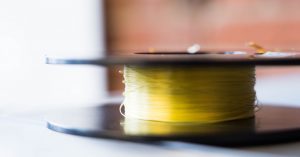

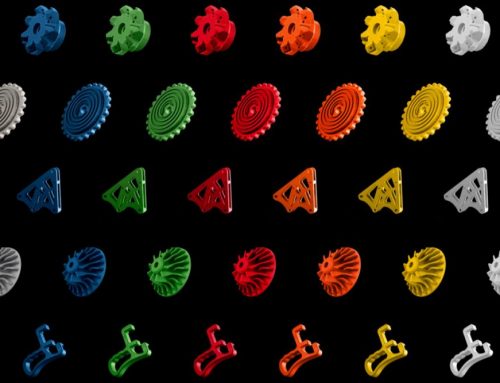

Most people think of Yoda heads and fidget spinners as soon as they hear the term “3D printing”. Some people may think of building prototypes, but modern 3D printing goes way beyond that.

At Mark3D, we understand “3D printing” to mean; high-strength components, robot grippers, assembly aids, spare parts and so on. How is that possible? Markforged’s advanced 3D printers can print carbon fiber reinforced parts that are stronger than aluminum. This allows high-strength utility parts, tools, fixtures and small batches to be produced quickly and inexpensively overnight to meet industrial requirements.

High strength components overnight

Thanks to Markforged 3D printers, high-strength components can be produced overnight. This allows the production of cost-effective spare parts and prevents long machine downtime. Instead of having to wait for suppliers, individual components are simply 3D printed. This creates a wide range of applications that make daily operations more convenient, faster and more cost-effective.

DUNLOP Systems and Components could make exactly this experience and thus remains competitive in the long run. We have summarized this experience for you in a user report. Read report now.

The Markforged Mark Two 3D printer quickly paid for itself, resulting in significant cost savings, streamlined processes and increased manufacturing flexibility.

SIEMENS was also able to save $8000 and around 35 weeks delivery time per component. Simply because cost-consuming components were questioned and redesigned with the possibilities of additive manufacturing.

Staying competitive

Modern manufacturing requires new tools, perspectives and ways of thinking in order to be able to compete in the highly competitive markets. Additive manufacturing can drastically reduce the cost of tools and parts that are required for maintenance, repair and operation. Many manufacturers, such as DUNLOP and SIEMENS, have significantly improved the competitiveness of their operations by using additive manufacturing solutions for high-strength components, such as Markforged’s Industrial Series printers. These fully equipped machines enable rapid production of tooling and MRO equipment robust enough to meet the demands of the factory floor while significantly reducing tooling costs and lead times.

Advanced printing materials, such as continuous carbon fiber, reinforce components to achieve strengths beyond those of 6061-T6 aluminum and enable geometric complexities that exceed the capabilities of 6-axis machining centers – all controlled by powerful, simple printer management software that requires no CAM or NC programming skills. The Markforged Industrial Series is a critical tool for reducing costs and improving performance in your manufacturing strategy.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

I think most of the people like 3D printing. It’s a great technology to print objects at low cost, that’s why it’s gaining popularity.

In my opinion, additive manufacturing is developing so fast because of the high flexibility of this technology. You will never be able to change the production process as quickly and deeply as you can with additive manufacturing facilities.