Can 3D printed robot grippers be 97% cheaper?

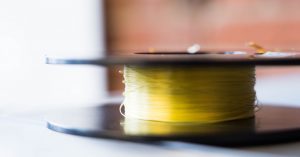

In practice, the economic and physical limitations of conventional manufacturing processes often make robot grippers heavy, bulky and inefficient – resulting in high costs with long lead times. 3D-printed robot grippers are very robust, yet lightweight and can be manufactured quickly at a fraction of the cost. With Markforged’s continuous fiber technology, these parts can withstand thousands of cycles without failure. A new set of robot grippers can be made in less than a day with the MarkTwo and is as strong as aluminium – at half the weight!

VComparison CNC to 3D printing:

Production time: 93% shorter

Production costs: 97% cheaper

Have you already discovered possibilities for additive manufacturing in your company? Write it in the comments.

Request a demo!

Feel the strength of continuous fiber for yourself.

![Jet Dragster Racing [Video] with 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Josette-Roach-500x383.png)

![Hollywood Propmaster [Video] 3D Printing with Markforged](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Thingergy-26-scaled-500x383.jpg)

![BattleBots Valkyrie [Video] Using 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/BattleBots-11-500x383.png)

Leave A Comment