#08 Road to Christmas – Peil Maschinenbautechnik

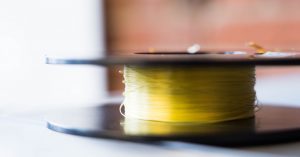

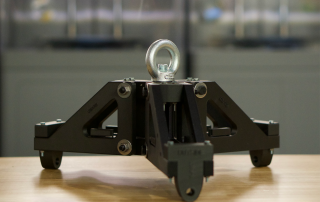

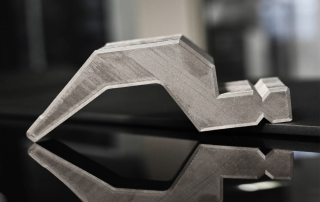

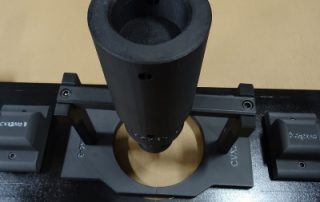

#08 Road to Christmas – Peil Maschinenbautechnik 3D printing in special machines construction! 💪 „The great advantage of additive manufacturing is that the material on the spool can be used to produce all shapes.“ – Thomas Peil, Managing Director of Peil Maschinenbautechnik ✔ Better dynamics ✔ Huge time-saver ✔ Sound insulation Read the [...]