#04 Road to Christmas – Nieka

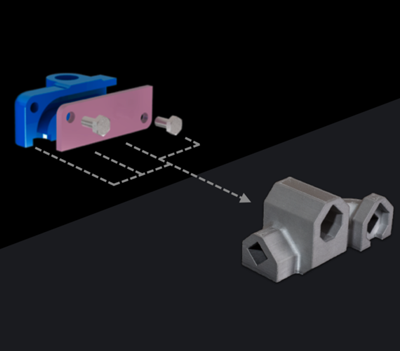

Utilizing Inconel 625 for rapid and repeated temperature cycling! 💪

“By adding the Markforged Metal X in-house, there’s virtually no lead time on these parts anymore!“ – Louis Croisetière PH.D, Founder of Nieka Systems

✔ 80K USD saved per year ✔ 86 % saved in lead time ✔ 1,5 years to achieve ROI

Read the whole Case Study from Nieka!

What would you 3D print with the Metal X System ❓

Request a demo!

Feel the strength of 3D printed metal for yourself.

Learn more about applications with metal 3D printing!

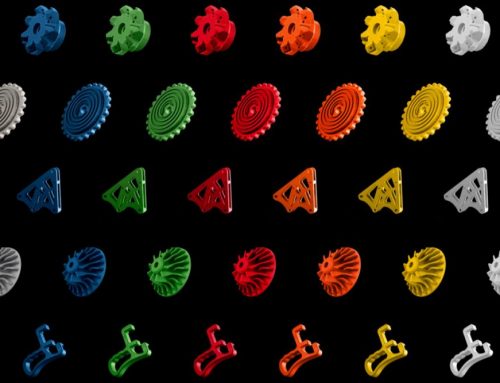

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

Leave A Comment