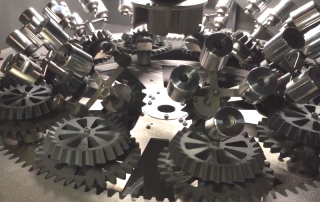

Automotive parts with metal 3D printing

Components for classic cars out of a modern 3D-printer? 🤔 RPG Industries, Inc. is always looking for ways to stay cutting edge in a saturated industry. The team decided to bring in a Markforged Metal X system and a Mark Two professional-series 3D printer, which they have used for a wide range of applications. [...]