Carbon fiber-reinforced, 3D printed tube bending die ✅

Rebula MTB builds custom, high-performance mountain and gravel bikes for riders with big appetites for demanding terrain, and who want a bike that feels like an extension of themselves, tailored to their unique riding style.

To hit their goals and delight their customers, they are constantly building custom tools and fixtures and experimenting with new manufacturing processes like composite reinforced 3D printing to help keep themselves agile.

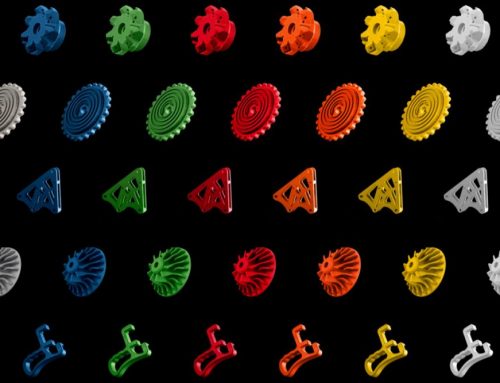

Their team is currently using this continuous carbon fiber and Onyx 3D printed tubebending die to form the curvatures of the aluminum chainstays for a new bike model that they’re ramping up for production. An off-the-shelf die with a matching profile of the aluminum tube stock wasn’t available for their bender, so a custom die was required and machining one from steel was expensive.

Since the design was in flux during their R&D stage, 3D printing the die on a Markforged X7 enabled them to rapidly-produce a high-strength tool that they could inexpensively iterate on if the design needed to change.

The best part? The bend die is working so well that it’s now Rebula MTB’s production tool as they bring their new model to market.

This is manufacturing redefined!

👉 What would you print first with carbon fibre? Write it in the comments ⤵

Request a demo!

Feel the strength of continuous fiber for yourself.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

Leave A Comment